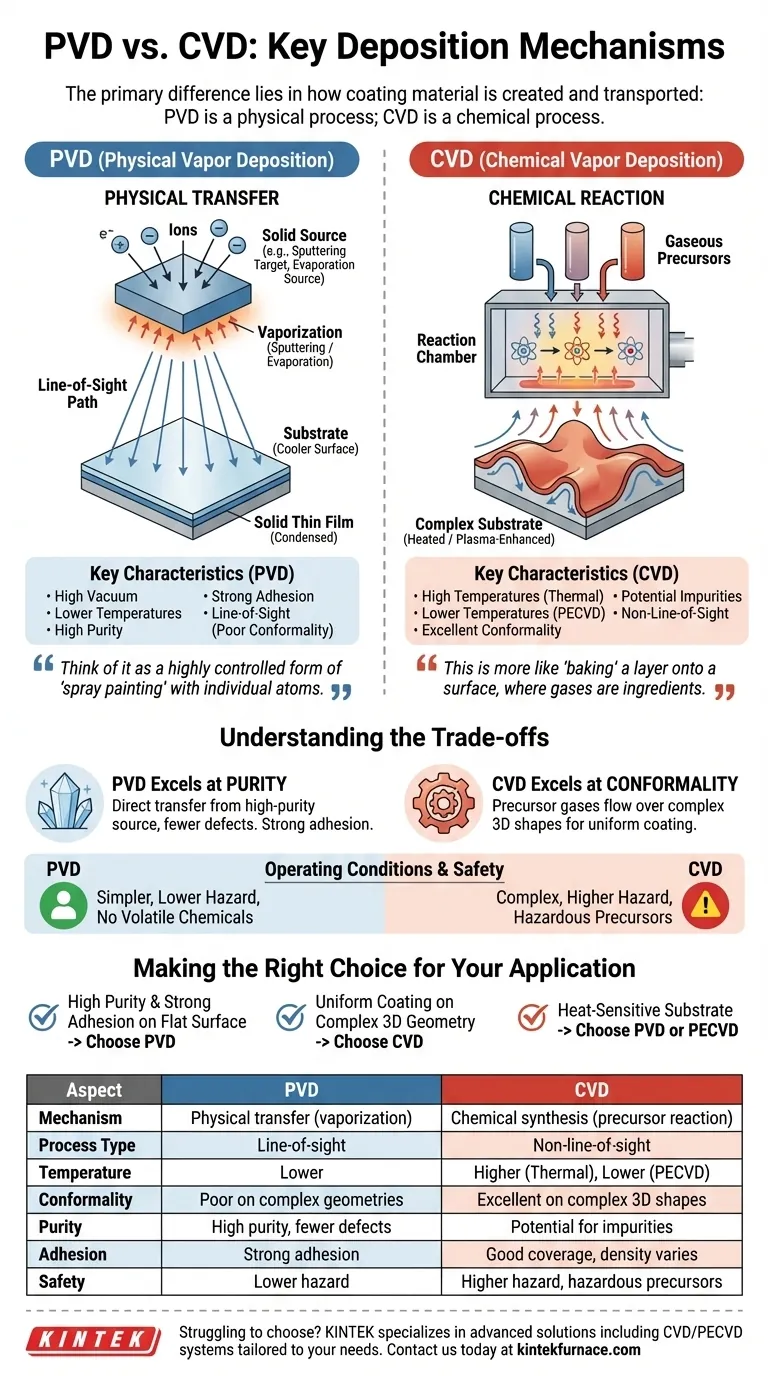

At its core, the primary difference between Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) lies in how the coating material is created and transported. PVD is a physical process that transfers an existing material from a source to a substrate, while CVD is a chemical process that synthesizes a new solid material directly on the substrate's surface from gaseous precursors.

The choice between PVD and CVD is not about which is "better," but which is the right tool for the job. PVD physically moves atoms from a source to a target, offering high purity, while CVD uses gas-phase chemical reactions to build a film, offering superior coverage on complex shapes.

The Mechanics of Physical Vapor Deposition (PVD)

The Core Principle: A Physical Transfer

PVD is a line-of-sight process fundamentally based on physics. It involves taking a solid source material, turning it into a vapor, and having it condense onto a substrate to form a thin film.

Think of it as a highly controlled form of "spray painting" with individual atoms or molecules in a high-vacuum environment.

The Process in Action

The process begins by creating a vapor from a solid source using methods like sputtering (bombarding the source with ions) or evaporation (heating it). This vapor then travels in a straight line through a vacuum chamber and deposits onto the cooler substrate, forming a solid, thin film.

Because it is a line-of-sight process, areas not directly "visible" to the source material will not get coated effectively.

Key Characteristics of PVD

PVD operates in a high vacuum and can often be performed at lower temperatures than traditional CVD. This makes it suitable for coating materials that are sensitive to heat.

The resulting films are known for their high purity, density, and strong adhesion to the substrate. Control is relatively straightforward, governed by factors like deposition time and vaporization rate.

The Mechanics of Chemical Vapor Deposition (CVD)

The Core Principle: A Chemical Reaction

CVD is fundamentally a chemistry-based process. It does not transfer an existing material; instead, it synthesizes a new material directly on the substrate from chemical precursors.

This is more like "baking" a layer onto a surface, where gases are the ingredients that react to form the solid coating.

The Process in Action

In CVD, one or more volatile precursor gases are introduced into a reaction chamber. Energy, typically in the form of high heat, is applied to initiate chemical reactions.

These reactions produce a solid material that deposits uniformly onto the substrate, creating the desired thin film. Because the precursor gases can flow around complex shapes, CVD is not a line-of-sight process.

The Role of Temperature and Plasma

Traditional thermal CVD requires very high temperatures (hundreds or even thousands of degrees Celsius) to drive the necessary chemical reactions.

A modern variant, Plasma-Enhanced CVD (PECVD), uses a plasma to excite the precursor gases. This allows the chemical reactions to occur at much lower temperatures, expanding the range of substrates that can be coated without heat damage.

Understanding the Trade-offs

Conformality vs. Purity

CVD excels at conformality. Since the precursor gases can flow and react on all exposed surfaces, CVD can create highly uniform coatings on complex, three-dimensional geometries with trenches and undercuts.

PVD excels at purity. Because the material is simply transferred from a high-purity source to the substrate without intermediate chemical reactions, PVD films are generally purer and have fewer incorporated defects.

Operating Conditions

CVD often involves high temperatures and hazardous chemical precursors, making the process more complex and posing greater safety challenges.

PVD is a mechanically simpler process that typically operates at lower temperatures and avoids the hazards of volatile precursor chemicals.

Film Properties and Adhesion

PVD films are often very dense and exhibit excellent adhesion, making them ideal for applications requiring durability and precise property control, such as optical coatings or hard coatings on tools.

CVD films, while offering great coverage, can sometimes have lower density or introduce impurities from the chemical reactions, which must be carefully managed.

Making the Right Choice for Your Application

Choosing between these methods requires a clear understanding of your primary goal.

- If your primary focus is high purity and strong adhesion on a relatively flat surface: Choose PVD for its clean, direct physical transfer mechanism.

- If your primary focus is uniformly coating a complex 3D geometry: Choose CVD for its superior conformality and ability to cover non-line-of-sight surfaces.

- If your substrate is sensitive to heat: Your best options are PVD or Plasma-Enhanced CVD (PECVD), as traditional high-temperature CVD could cause damage.

Ultimately, understanding the fundamental difference between physical transport and chemical reaction empowers you to select the precise deposition technology for your specific need.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Deposition Mechanism | Physical transfer of material via vaporization (e.g., sputtering, evaporation) | Chemical synthesis from gaseous precursors via reactions |

| Process Type | Line-of-sight | Non-line-of-sight |

| Temperature | Lower temperatures, suitable for heat-sensitive materials | Higher temperatures (thermal CVD), lower with PECVD |

| Conformality | Poor on complex geometries | Excellent on complex 3D shapes |

| Purity | High purity, fewer defects | Potential for impurities |

| Adhesion | Strong adhesion, dense films | Good coverage, may vary in density |

| Safety | Lower hazard, no volatile chemicals | Higher hazard, uses hazardous precursors |

Struggling to choose between PVD and CVD for your laboratory needs? At KINTEK, we specialize in advanced high-temperature furnace solutions, including CVD/PECVD Systems and more, tailored to your unique experimental requirements. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to ensure precise performance for your applications. Contact us today to discuss how our expertise can optimize your deposition processes and enhance your lab's efficiency!

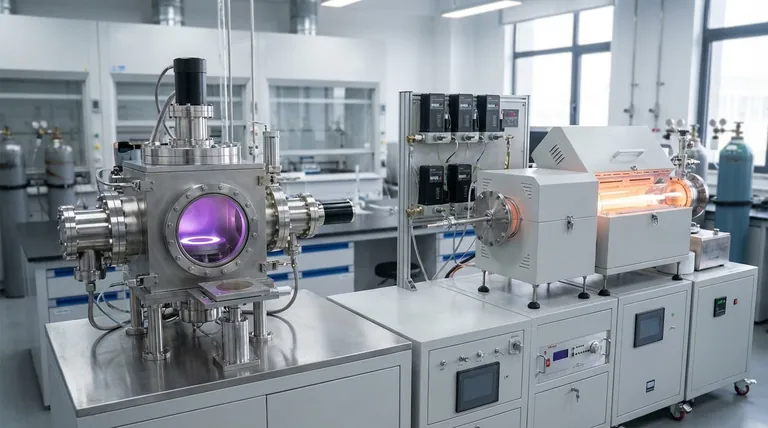

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab