In essence, Molybdenum Disilicide (MoSi₂) heating elements are the definitive choice for high-temperature industrial and laboratory applications where long-term stability, thermal efficiency, and resistance to oxidation are paramount. They excel in processes like glass production, ceramics sintering, and metallurgy that operate continuously at extreme temperatures where element failure would be catastrophic.

The decision to use a MoSi₂ heating element is not just about reaching a high temperature; it's an investment in process reliability. Their primary value lies in maintaining those extreme temperatures consistently over long periods, minimizing costly furnace downtime in critical production environments.

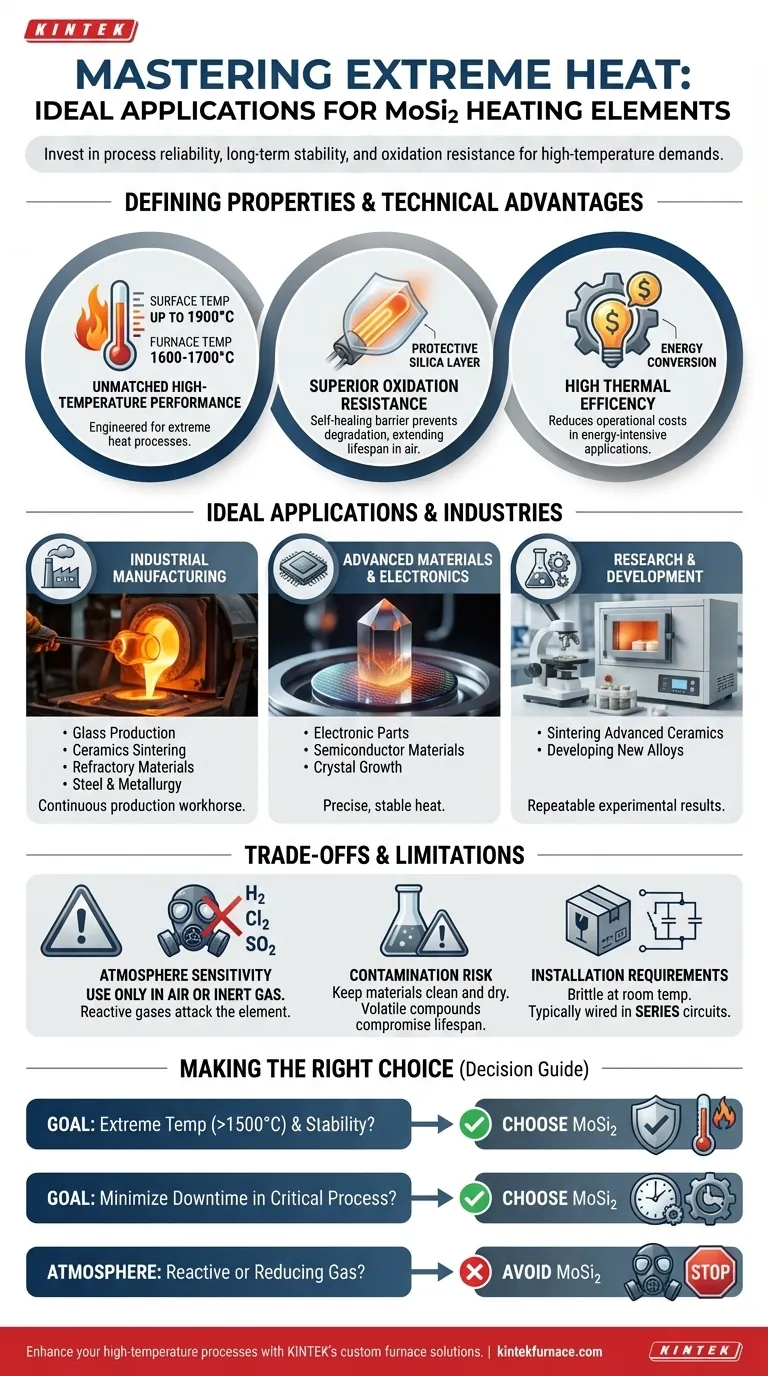

The Defining Properties of MoSi₂ Elements

To understand where MoSi₂ elements shine, you must first understand their core technical advantages. These properties make them uniquely suited for the most demanding heating tasks.

Unmatched High-Temperature Performance

MoSi₂ elements are engineered for extreme heat. They can operate with a surface temperature reaching up to 1800-1900°C, allowing for furnace chamber temperatures between 1600°C and 1700°C.

This capability places them in a class above many other heating elements, making them essential for processes requiring the synthesis or treatment of advanced materials.

Superior Oxidation Resistance

At high temperatures, these elements form a protective layer of silica glass on their surface. This layer prevents further oxidation, which is the primary cause of degradation in most heating elements.

This self-healing protective barrier is why MoSi₂ elements can have a significantly longer lifespan than alternatives, especially when operated consistently above 1500°C.

High Thermal Efficiency

Like other advanced ceramic heaters, MoSi₂ elements are highly efficient at converting electrical energy into heat. This efficiency is critical for managing operational costs in energy-intensive industrial furnace applications.

Ideal Applications and Industries

The unique properties of MoSi₂ dictate its use in specific, high-value sectors where performance and reliability justify the investment.

Industrial Manufacturing

MoSi₂ is a workhorse in heavy industry. It is widely used in furnaces for the production of glass, ceramics, refractory materials, steel, and for metallurgical processes.

The element's longevity ensures these continuous production lines can run without interruption for maintenance.

Advanced Materials and Electronics

The manufacturing of specialized components relies on the precise and stable heat that MoSi₂ provides. This includes producing electronic parts, semiconductor materials, and crystals.

These applications demand a clean heating environment with minimal temperature fluctuation, which MoSi₂ elements deliver.

Research and Development

In laboratory settings and for materials research, MoSi₂ elements are used in high-temperature furnaces for sintering advanced ceramics and developing new alloys.

Their stability ensures that experimental results are repeatable and not compromised by heater degradation.

Understanding the Trade-offs and Limitations

No technology is without its constraints. Being aware of the specific operational requirements for MoSi₂ is critical for success.

Extreme Sensitivity to Atmospheres

This is the most critical limitation. MoSi₂ elements should only be used in air or inert gas environments.

Active or reducing gases like hydrogen (H₂), chlorine (Cl₂), and sulfur dioxide (SO₂) will chemically attack the element and its protective silica layer, causing rapid failure.

Risk of Contamination

The elements can be vulnerable to contamination. For example, technicians must ensure materials like colored or painted zirconia are completely dry before heating.

Improper furnace maintenance or introducing volatile compounds can compromise element lifespan and performance.

Specific Installation Requirements

MoSi₂ elements are typically brittle at room temperature and must be handled with care. They are often produced in "U," "W," or "L" shapes and are wired in series circuits for operation. This differs from other element types and must be considered in the furnace design.

Making the Right Choice for Your Process

Your specific goal will determine if MoSi₂ is the correct solution for your application.

- If your primary focus is extreme temperatures (>1500°C) and long-term stability: MoSi₂ is the superior choice due to its exceptional oxidation resistance and longevity in air.

- If your primary focus is minimizing furnace downtime in a critical process: The durability of MoSi₂ makes it a sound investment for continuous production in industries like aerospace or automotive parts manufacturing.

- If your process involves a reactive or reducing gas atmosphere: You must avoid MoSi₂ and select an alternative element material specifically designed for those conditions.

Ultimately, choosing MoSi₂ is an investment in stable, reliable performance for your most demanding high-temperature applications.

Summary Table:

| Property | Benefit | Ideal Application |

|---|---|---|

| High-Temperature Performance (up to 1900°C) | Enables extreme heat processes | Glass production, ceramics sintering |

| Superior Oxidation Resistance | Long lifespan in air or inert gases | Metallurgy, advanced materials |

| High Thermal Efficiency | Reduces operational costs | Industrial manufacturing, R&D labs |

| Sensitivity to Atmospheres | Requires careful environment control | Avoid in reactive gas settings |

Enhance your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to discuss how our reliable MoSi2 heating elements can minimize downtime and boost efficiency in your lab or production line!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics