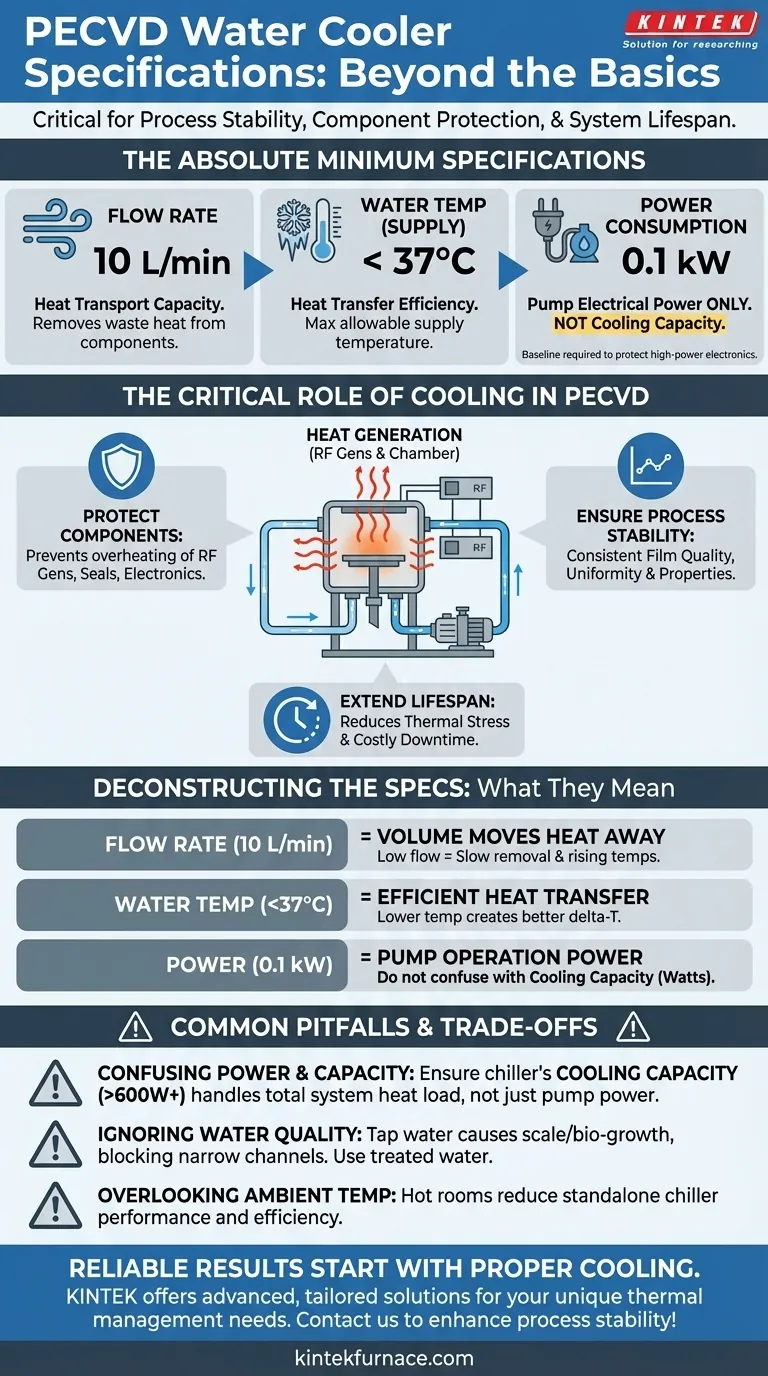

At a minimum, the PECVD water cooler requires a flow rate of 10 L/min and must be supplied with cooling water that remains below 37°C. The cooler itself consumes approximately 0.1 kW of power to operate its pump and internal systems. These specifications are the absolute baseline required to protect the system's high-power electronics and ensure process stability.

Understanding these numbers is not just about checking a box; it's about managing the thermal load of the entire deposition system. Insufficient cooling is a primary cause of process drift, component failure, and inconsistent film quality.

The Role of Cooling in a PECVD System

A Plasma-Enhanced Chemical Vapor Deposition (PECVD) system is a thermally intensive environment. Heat is generated intentionally by heaters and as a byproduct of high-power electronics. Effective cooling is non-negotiable for stable operation.

Protecting Critical Components

The primary purpose of the water cooler is to remove waste heat from high-power and temperature-sensitive components. This includes the RF generators (e.g., 30/300W and 600W units) and potentially the vacuum chamber walls and other electronics. Without constant cooling, these components would quickly overheat and fail.

Ensuring Process Stability

The characteristics of the plasma and the rate of chemical reactions are highly dependent on temperature. The water cooler ensures a stable thermal baseline for the chamber and power delivery systems. This consistency is critical for achieving reproducible film thickness, uniformity, and material properties from one run to the next.

Extending System Lifespan

Operating electronics and vacuum components at elevated temperatures drastically shortens their lifespan. Proper cooling mitigates thermal stress on O-rings, seals, and circuit boards, preventing premature failure and reducing costly downtime.

Deconstructing the Water Cooler Specifications

Each specification serves a distinct purpose in the overall thermal management strategy. Understanding what each one means is key to providing adequate cooling.

Flow Rate: 10 L/min

This specifies the volume of cooling water that must pass through the system's cooling loop every minute. It represents the capacity to transport heat away from the components. Too low a flow rate means heat is removed too slowly, causing component temperatures to rise even if the water itself is cold.

Water Temperature: Below 37°C

This is the maximum allowable temperature for the water being supplied to the PECVD system. The cooler water provides a larger temperature differential (delta-T) between the coolant and the hot component, enabling more efficient heat transfer. Operating closer to this limit reduces your safety margin.

Power: 0.1 kW

This figure most likely refers to the electrical power consumed by the water cooler's pump and internal controls. It is not a measure of the cooler's heat removal capability, which is typically rated in Watts or BTU/hr of "cooling capacity."

Understanding the Trade-offs and Common Pitfalls

Simply meeting the minimum numbers is not enough. A robust cooling strategy requires a deeper understanding of potential failure points.

Confusing Cooler Power with Cooling Capacity

The most critical mistake is assuming the 0.1 kW power consumption is the cooling capacity. You must ensure your chiller's cooling capacity can handle the full heat load from the PECVD system—primarily its RF generators (totaling over 600 W) and any chamber heating.

Ignoring Facility Water Quality

If connecting to a facility loop, water quality is paramount. Using standard tap water can lead to mineral deposits (scale) and biological growth inside the narrow cooling channels of the PECVD system. This buildup acts as an insulator, drastically reducing cooling efficiency and potentially causing a complete blockage. Distilled or properly treated water is often required.

Overlooking Ambient Conditions

A standalone chiller's performance depends on the ambient temperature of the room it's in. A chiller operating in a hot, poorly ventilated room will struggle to cool the water down to the target temperature, even if it is functioning correctly.

Making the Right Choice for Your Goal

Your approach to cooling will depend on your specific setup and resources.

- If your primary focus is connecting to a facility-wide chilled water loop: Verify that the loop can consistently provide water below 37°C at a flow rate of at least 10 L/min, even during periods of high facility-wide demand.

- If your primary focus is purchasing a dedicated chiller: Select a chiller whose cooling capacity (in Watts) exceeds the PECVD's total heat load and can deliver 10 L/min of water at your desired temperature.

- If your primary focus is troubleshooting an unstable process: Measure the flow rate and temperature of your cooling water both entering and exiting the PECVD system to confirm your cooler is performing to specification under load.

Properly implementing these cooling specifications is the foundation for reliable and repeatable results from your PECVD system.

Summary Table:

| Specification | Requirement | Purpose |

|---|---|---|

| Flow Rate | 10 L/min | Transports heat away from components to prevent overheating |

| Water Temperature | Below 37°C | Enables efficient heat transfer for stable process conditions |

| Power Consumption | 0.1 kW | Powers the cooler's pump and internal systems, not cooling capacity |

Ensure your PECVD system operates flawlessly with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored cooling systems, including our CVD/PECVD Systems, backed by deep customization to meet your unique thermal management needs. Contact us today to discuss how we can enhance your process stability and extend equipment lifespan!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings