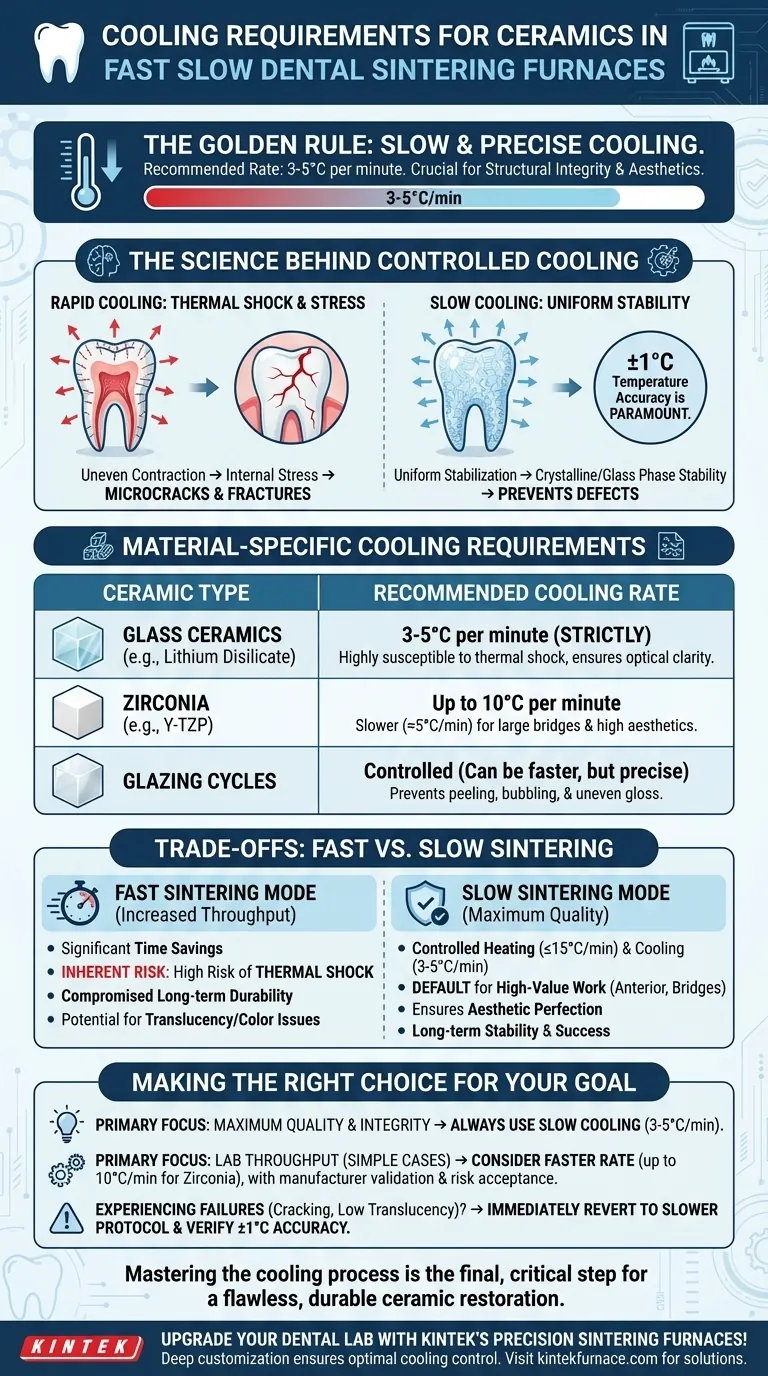

For optimal results, ceramics in a Fast Slow Dental Sintering Furnace must be cooled slowly and precisely. The recommended cooling rate is between 3-5°C per minute to prevent internal stress and cracking. This controlled process is just as critical as the heating cycle for ensuring the final restoration's structural integrity and aesthetic quality.

The core challenge in dental sintering is not just reaching a peak temperature, but managing the entire thermal cycle. A controlled cooling phase is essential to mitigate thermal shock, which prevents the formation of microcracks and ensures the long-term stability and success of the ceramic restoration.

The Science Behind Controlled Cooling

The cooling phase is where the final properties of the ceramic are locked in. Rushing this stage introduces significant risk, turning a potentially perfect restoration into a failure.

Preventing Thermal Shock and Internal Stress

As a ceramic restoration cools, its outer surface loses heat faster than its inner core. A rapid cooling rate creates a large temperature difference between the surface and the core.

This differential causes the material to contract unevenly, building up internal stress. If this stress exceeds the material's strength, it will manifest as microcracks or even catastrophic fractures.

Ensuring Crystalline and Glass Phase Stability

Slow cooling allows the material's internal structure to stabilize uniformly. In zirconia, this ensures a proper crystalline transformation.

For glass ceramics, it prevents the uneven flow of the glass phase, which is critical for achieving the desired translucency and preventing deformation. Precise temperature control, with an accuracy of ±1°C, is paramount during this process.

Material-Specific Cooling Requirements

Different ceramics have different thermal properties. Using a one-size-fits-all program is a common cause of inconsistent results. Always start with the ceramic manufacturer's recommendations and create dedicated programs for each material.

For Glass Ceramics

Glass ceramics are highly susceptible to thermal shock due to their amorphous structure. Adhering strictly to a slow cooling rate of 3-5°C per minute is non-negotiable for preventing cracks and ensuring optimal aesthetics.

For Zirconia

Zirconia is generally more robust than glass ceramics, allowing for a slightly faster cooling rate of up to 10°C per minute. However, for large-span bridges or highly aesthetic anterior cases, a slower rate closer to 5°C per minute remains the safest approach to guarantee stability.

For Glazing

Glazing cycles are much shorter and occur at lower temperatures (e.g., 800-900°C). While the cooling can be faster than a full sintering cycle, it must still be controlled to prevent the glaze from peeling, bubbling, or developing an uneven surface gloss.

Understanding the Trade-offs: Fast vs. Slow Sintering

The primary benefit of a "Fast Slow" furnace is its flexibility. However, understanding the trade-offs between these modes is crucial for making informed decisions.

The Lure of Fast Sintering

The "fast" mode is designed to increase lab throughput. It dramatically shortens the entire heating and cooling cycle, offering a significant time savings per unit.

The Inherent Risk of Rapid Cooling

This speed comes at a cost. A rapid cooling cycle dramatically increases the risk of thermal shock, leading to compromised restorations that may look acceptable initially but can fail prematurely once in service. It can also negatively impact translucency and color matching.

When to Prioritize Slow Sintering

The slow sintering mode, with its controlled heating (≤15°C/minute) and cooling (3-5°C/minute) rates, should be your default for all high-value work. This includes anterior crowns, multi-unit bridges, and any case where aesthetic perfection and long-term durability are the primary goals.

Making the Right Choice for Your Goal

Use these guidelines to select the appropriate cooling protocol for your specific objective.

- If your primary focus is maximum quality and structural integrity: Always use a slow cooling rate, ideally between 3-5°C per minute, especially for glass ceramics and complex zirconia frameworks.

- If your primary focus is maximizing lab throughput for simple cases: A faster rate up to 10°C per minute may be used for single-unit zirconia posteriors, but you must validate this with the material manufacturer and accept the increased risk.

- If you are experiencing failures like cracking or low translucency: Immediately revert to a slower cooling protocol and verify that your furnace's temperature is calibrated to maintain an accuracy of ±1°C.

Mastering the cooling process is the final, critical step in delivering a flawless and durable ceramic restoration.

Summary Table:

| Aspect | Recommendation |

|---|---|

| General Cooling Rate | 3-5°C per minute |

| Glass Ceramics Cooling | 3-5°C per minute |

| Zirconia Cooling | Up to 10°C per minute (slower for complex cases) |

| Temperature Accuracy | ±1°C |

| Key Benefits | Prevents internal stress, microcracks, and ensures stability |

Upgrade your dental lab with KINTEK's precision sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs. Our deep customization ensures optimal cooling control for flawless ceramic restorations. Contact us today to enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations