Ultimately, inconsistent firing quality in a dental sintering furnace directly leads to compromised restorations that are weaker, aesthetically flawed, and may not fit properly. This happens because uneven temperatures cause the ceramic material to sinter incompletely or excessively in different areas, undermining its final structural and visual properties.

The core issue is a loss of predictability. When a furnace cannot deliver consistent and uniform heat, it turns a precise manufacturing process into a game of chance, risking costly material waste, frustrating remakes, and a loss of clinical confidence.

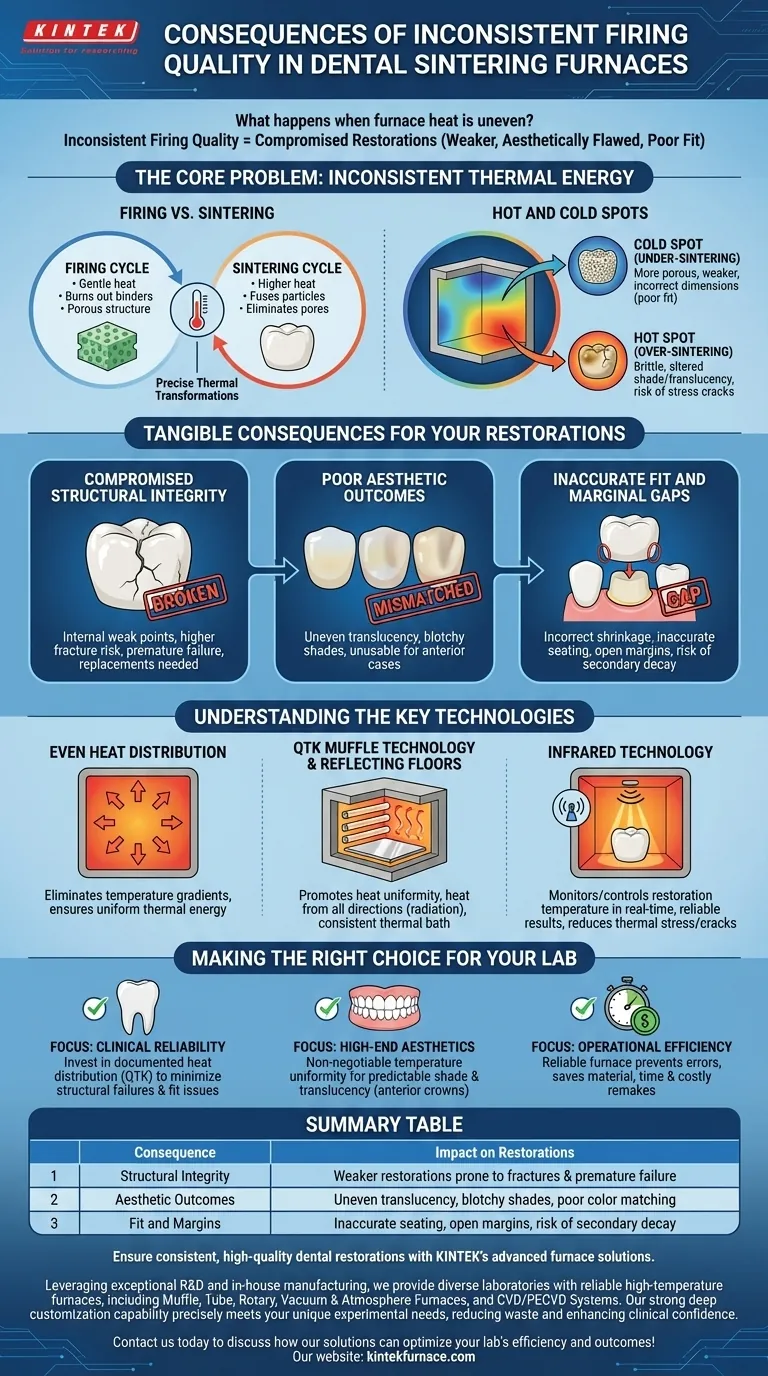

The Core Problem: Inconsistent Thermal Energy

The processes of firing and sintering are precise thermal transformations. Any deviation from the target temperature profile, even in a small section of the furnace, can have significant consequences for the final product.

Firing vs. Sintering

First, the firing cycle gently heats the "green state" ceramic to burn out organic binding materials, creating a stable but porous structure. Then, the sintering cycle heats the material to a much higher temperature, causing the ceramic particles to fuse, eliminating pores and increasing the material's density to its final intended state.

Both stages rely on absolute temperature accuracy and uniformity.

The Impact of Hot and Cold Spots

Inconsistent heating creates "hot spots" and "cold spots" within the furnace chamber.

A cold spot results in under-sintering. The ceramic in this area will be more porous, weaker, and will not shrink to the correct dimensions, leading to a poor marginal fit.

A hot spot can cause over-sintering or burning. This can make the material brittle, alter its shade and translucency, and increase the risk of stress cracks forming as the restoration cools.

The Tangible Consequences for Your Restorations

These thermal inconsistencies manifest as clear, clinical failures that directly impact your lab's efficiency and your patients' outcomes.

Compromised Structural Integrity

The most critical consequence is a weaker restoration. Under-sintered areas create internal weak points, drastically increasing the risk of fractures once the crown or bridge is in function. This leads to premature failure and the need for a replacement.

Poor Aesthetic Outcomes

Aesthetics depend entirely on achieving the correct material density and crystalline structure. Inconsistent heating can cause blotchy or uneven translucency, and it can prevent the restoration from matching the target shade, rendering it unusable for anterior cases.

Inaccurate Fit and Marginal Gaps

Sintering causes the ceramic to shrink by a precise, calculated amount. If parts of the restoration are under-sintered due to cold spots, they will not shrink correctly. This results in a restoration that does not seat properly, creating open margins that invite secondary decay.

Understanding the Key Technologies

Preventing these issues is a matter of furnace design and technology. The goal is to create a perfectly uniform thermal environment for every cycle.

Even Heat Distribution

This is the fundamental principle. High-quality furnaces are engineered to eliminate temperature gradients within the firing chamber, ensuring every part of every restoration receives the exact same amount of thermal energy.

QTK Muffle Technology and Reflecting Floors

These are specific design features that promote heat uniformity. A QTK (Quartz Tube Kiln) muffle combined with a reflecting floor ensures heat is distributed evenly from all directions through radiation, rather than just from the heating elements themselves. This envelops the restorations in a consistent thermal bath.

The Role of Infrared Technology

Modern furnaces often use infrared technology to monitor and control the temperature of the restorations directly. This provides more reliable firing results by allowing the furnace to react in real-time, reducing thermal stress on the ceramic and minimizing the risk of cracks or warping.

Making the Right Choice for Your Lab

Selecting a furnace requires balancing budget with the need for predictable, high-quality results. Your decision should be guided by the consequences you most need to avoid.

- If your primary focus is clinical reliability: Invest in a furnace with documented heat distribution technology (like QTK) to minimize the risk of structural failures and inaccurate fits.

- If your primary focus is high-end aesthetics: For anterior crowns and veneers, temperature uniformity is non-negotiable to achieve predictable shade and translucency.

- If your primary focus is operational efficiency: Preventing firing errors with a reliable furnace is a direct cost-saving measure that reduces wasted material, technician time, and costly remakes.

Ultimately, consistent firing quality is the foundation upon which predictable, high-quality dental restorations are built.

Summary Table:

| Consequence | Impact on Restorations |

|---|---|

| Structural Integrity | Weaker restorations prone to fractures and premature failure |

| Aesthetic Outcomes | Uneven translucency, blotchy shades, and poor color matching |

| Fit and Margins | Inaccurate seating, open margins, and risk of secondary decay |

Ensure consistent, high-quality dental restorations with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, reducing waste and enhancing clinical confidence. Contact us today to discuss how our solutions can optimize your lab's efficiency and outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns