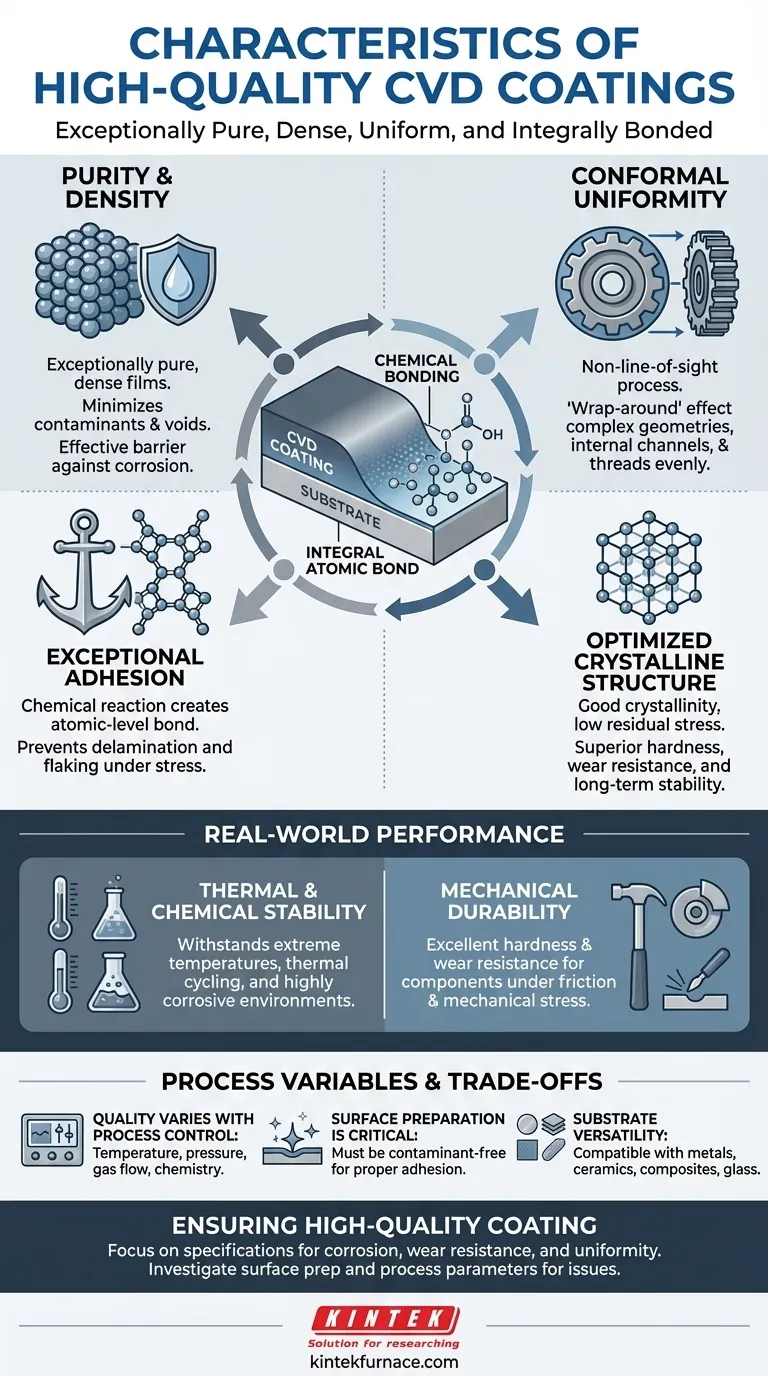

In essence, a high-quality Chemical Vapor Deposition (CVD) coating is defined by its exceptional purity, density, uniformity, and integral adhesion to the substrate. These characteristics are not merely surface treatments; they create a new, functional surface at an atomic level, delivering superior performance that is highly uniform across even the most complex geometries.

The true value of CVD lies in its ability to create a fundamentally new surface with precisely engineered properties. A successful process yields a coating that is not merely 'on' the substrate but is integrally bonded to it, offering predictable performance and complete coverage even in extreme conditions.

The Hallmarks of a Superior CVD Coating

A properly executed CVD process results in a film with a distinct set of desirable properties. These are the key indicators of a high-quality coating.

Purity and Density

Because the CVD process occurs in a controlled environment, it produces exceptionally pure and dense films. This process minimizes contaminants and voids, which are common failure points in other coating methods. A dense, non-porous layer is critical for creating an effective barrier against corrosion.

Conformal Uniformity (The "Wrap-Around" Effect)

CVD is a non-line-of-sight process. The gaseous precursors flow around the part, coating every exposed surface with remarkable uniformity. This "wrap-around" or conformal coverage is a key advantage, ensuring that internal channels, threads, and complex surface features receive the same high-quality coating as flat areas.

Exceptional Adhesion

The bond created by CVD is chemical, not mechanical. The coating is formed by a chemical reaction directly on the surface of the substrate, creating an exceptionally strong and adherent bond at the atomic level. This prevents the delamination and flaking that can plague physically deposited coatings under stress.

Optimized Crystalline Structure

A well-controlled CVD process produces a coating with good crystallinity and low residual stress. A defined crystalline structure often translates to superior hardness and wear resistance. Low internal stress is vital for the coating's long-term stability, preventing spontaneous cracking or failure during thermal cycling.

Performance Under Demanding Conditions

These intrinsic characteristics translate directly into superior real-world performance, making CVD a preferred solution for critical applications.

Thermal and Chemical Stability

The strong chemical bonds and high purity of CVD coatings give them the ability to withstand extreme temperatures, thermal cycling, and highly corrosive environments. They act as a chemically inert barrier, protecting the underlying substrate from chemical attack.

Mechanical Durability

The combination of high density, strong adhesion, and an optimized crystalline structure results in coatings with excellent hardness and wear resistance. This makes them ideal for components exposed to friction, abrasion, or mechanical stress.

Substrate Versatility

CVD is compatible with a wide range of substrate materials, including metals, ceramics, composites, and glass. This versatility allows engineers to apply high-performance surfaces to the most suitable base material for their application's structural needs.

Understanding the Trade-offs and Process Variables

Achieving a high-quality CVD coating is not automatic. It is a sophisticated process where quality is directly tied to control and preparation.

Why Quality Can Vary: The Process is Paramount

Reports of poor uniformity or particle inclusions in CVD coatings are not inherent flaws of the technology itself. Rather, they are symptoms of a sub-optimal or poorly controlled process. The quality of the final product is directly dependent on the precise management of temperature, pressure, gas flow rates, and chemistry.

The Critical Role of Surface Preparation

The substrate surface must be meticulously cleaned and prepared before coating. Any contaminants, oils, or oxides will interfere with the chemical reaction, leading to poor adhesion and coating defects. A perfect coating requires a perfect starting surface.

Material and Part Configuration

The success of the coating process also depends on the selection of the base material and the optimization of the part's geometry. Some substrates may require specific pre-treatments, and extremely complex internal features may necessitate adjustments to the process parameters to ensure uniform gas flow and deposition.

How to Ensure a High-Quality Coating

By focusing on the desired outcome, you can better specify your requirements and evaluate the quality of a CVD service.

- If your primary focus is corrosion resistance or purity: Emphasize the need for a dense, pinhole-free coating and verify that the process is designed to eliminate contaminants.

- If your primary focus is wear resistance on complex parts: Confirm that the process ensures conformal uniformity, especially on critical internal or detailed features.

- If you are facing coating failures or inconsistencies: Your investigation should focus on surface preparation protocols and process parameter control, not just the coating technology itself.

By understanding these fundamental characteristics, you can effectively specify and verify the quality of a CVD coating for your most critical applications.

Summary Table:

| Characteristic | Description |

|---|---|

| Purity and Density | Exceptionally pure, dense films with minimal contaminants and voids for effective corrosion barriers. |

| Conformal Uniformity | Non-line-of-sight process ensures uniform coverage on all surfaces, including complex geometries. |

| Exceptional Adhesion | Chemical bond at atomic level prevents delamination and flaking under stress. |

| Optimized Crystalline Structure | Good crystallinity and low residual stress for superior hardness and long-term stability. |

| Thermal and Chemical Stability | Withstands extreme temperatures and corrosive environments due to strong bonds and high purity. |

| Mechanical Durability | High hardness and wear resistance from density, adhesion, and crystalline structure. |

| Substrate Versatility | Compatible with metals, ceramics, composites, and glass for diverse applications. |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures precise coating performance for your unique experimental needs. Contact us today to enhance your lab's efficiency with tailored CVD coatings!

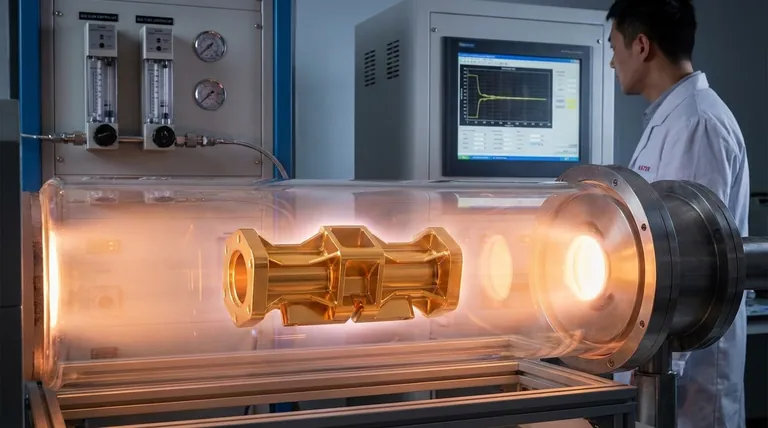

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods