In essence, a metal resistance heating element is a specially designed wire, ribbon, or strip that converts electrical energy into heat. Its primary characteristics are high electrical resistivity, durability, and the ability to withstand high temperatures without degrading. These elements are commonly used in a vast range of applications, from simple household appliances like toasters and hair dryers to high-temperature industrial furnaces.

The core challenge of resistance heating is not in generating heat, but in selecting the right material that can survive its operating environment. The choice of metal alloy is a critical trade-off between the required temperature, resistance to oxidation, and cost.

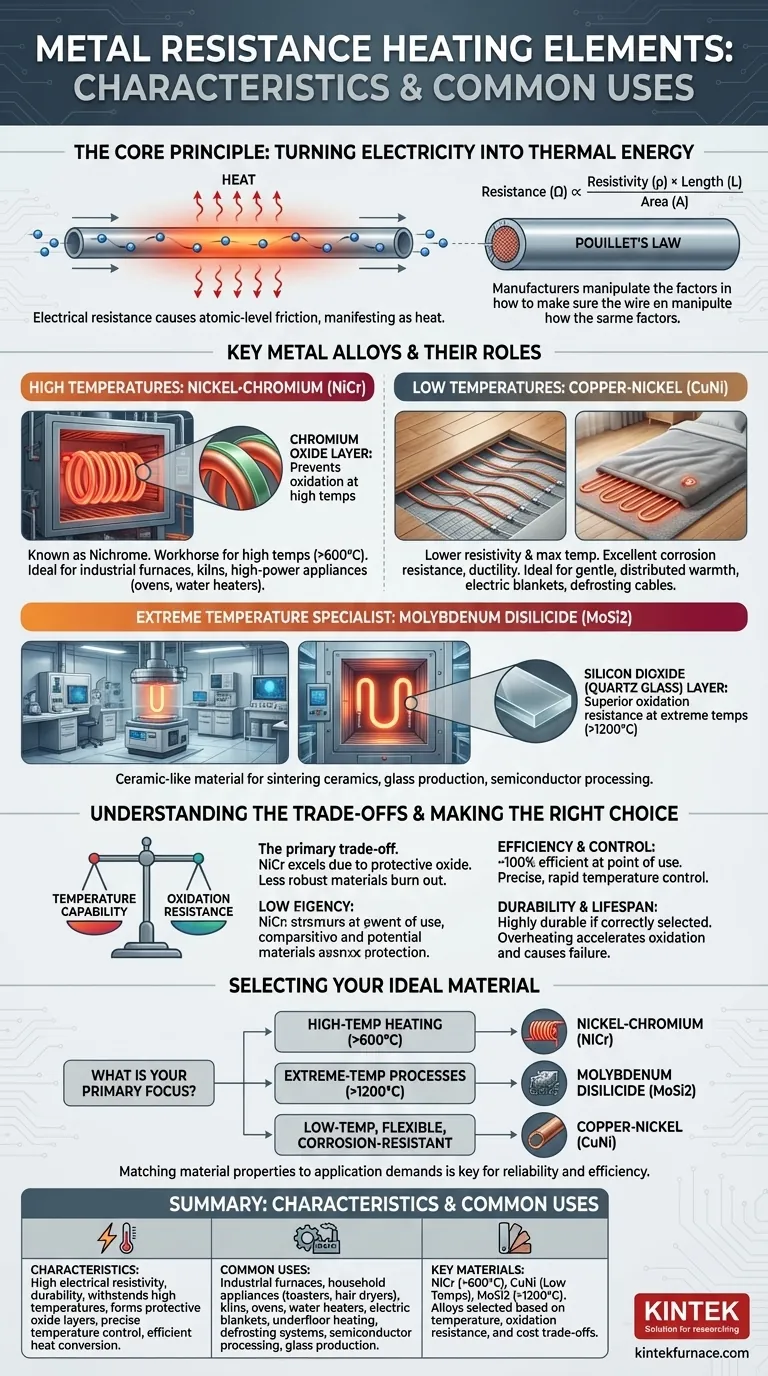

The Core Principle: How Resistance Creates Heat

Turning Electricity into Thermal Energy

Resistance heating works on a simple principle: when an electric current flows through a material, the material resists that flow. This opposition, known as electrical resistance, causes friction at the atomic level, which manifests as heat.

The Physics of Resistance

The amount of resistance is governed by Pouillet's law, which states that resistance is proportional to the material's inherent resistivity and its length, and inversely proportional to its cross-sectional area.

Heating element manufacturers use this law to create wires of a specific material, length, and thickness to produce a precise amount of heat for a given voltage.

Key Metal Alloys and Their Roles

Different applications demand different performance characteristics. The two primary families of metal alloys used for resistance heating are Nickel-Chromium (NiCr) and Copper-Nickel (CuNi).

Nickel-Chromium (NiCr) for High Temperatures

Nickel-Chromium alloys, often known by the trade name Nichrome, are the workhorses of high-temperature heating.

Their defining feature is the ability to form a protective outer layer of chromium oxide when heated. This layer is highly stable and prevents the metal underneath from oxidizing and failing, allowing it to operate reliably at very high temperatures.

This makes NiCr ideal for devices like industrial furnaces, kilns, and high-power appliances such as ovens and water heaters.

Copper-Nickel (CuNi) for Low Temperatures

Copper-Nickel alloys have lower resistivity and a lower maximum operating temperature compared to NiCr.

However, they offer excellent corrosion resistance and ductility. Their lower heat output makes them perfect for applications where gentle, distributed warmth is needed.

Common uses include low-temperature systems like electric blankets, underfloor heating, and defrosting cables.

Beyond Traditional Metals: High-Temperature Specialists

For the most extreme temperature demands, engineers turn to non-traditional materials that blur the line between metals and ceramics.

Molybdenum Disilicide (MoSi2)

Molybdenum disilicide (MoSi2) is a ceramic-like material valued for its exceptional oxidation resistance at very high temperatures.

When heated, it forms a protective layer of pure silicon dioxide, or quartz glass. This allows it to function in furnaces used for sintering ceramics, producing glass, and processing semiconductor materials.

Understanding the Trade-offs

Choosing a heating element involves balancing performance, lifespan, and cost. No single material is perfect for every situation.

The Temperature vs. Oxidation Dilemma

The primary trade-off is between temperature capability and resistance to oxidation. Materials like NiCr excel at high temperatures precisely because they form a protective oxide layer. Less robust materials will simply burn out.

Efficiency and Control

Metal resistance elements are nearly 100% efficient at converting electricity into heat at the point of use. They also allow for very precise and rapid temperature control, which is a major advantage over combustion-based heating.

Durability and Lifespan

A well-designed element made from the correct material for its application is highly durable. The most common cause of failure is operating the element above its rated temperature, which accelerates oxidation and causes it to become brittle and break.

Making the Right Choice for Your Application

Your specific goal dictates the ideal material. Use these guidelines to inform your decision.

- If your primary focus is high-temperature heating (above 600°C): Nickel-Chromium (NiCr) alloys are the standard choice due to their stable, protective oxide layer.

- If your primary focus is extreme-temperature industrial processes (above 1200°C): Molybdenum disilicide (MoSi2) elements are required for their superior performance in air.

- If your primary focus is low-temperature, flexible, or corrosion-resistant heating: Copper-Nickel (CuNi) alloys provide the necessary durability and gentle heat output for applications like heated blankets or defrosting systems.

Ultimately, matching the material's properties to the application's demands is the key to a reliable and efficient heating system.

Summary Table:

| Characteristic | Common Uses | Key Materials |

|---|---|---|

| High electrical resistivity, durability, withstands high temperatures | Industrial furnaces, household appliances (toasters, hair dryers) | Nickel-Chromium (NiCr), Copper-Nickel (CuNi), Molybdenum Disilicide (MoSi2) |

| Forms protective oxide layers, precise temperature control | Kilns, ovens, water heaters, electric blankets, underfloor heating | NiCr for high temps (>600°C), CuNi for low temps, MoSi2 for extreme temps (>1200°C) |

| Efficient heat conversion, rapid control, corrosion resistance | Defrosting systems, semiconductor processing, glass production | Alloys selected based on temperature, oxidation resistance, and cost trade-offs |

Need a custom high-temperature furnace solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your efficiency with tailored heating elements and systems!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions