The primary benefit of a vacuum furnace is its ability to produce exceptionally clean, bright parts by heat treating them in a controlled, contaminant-free environment. This process prevents surface reactions like oxidation and decarburization, ensuring precise control over the material's final properties and finish without the need for post-treatment cleaning.

While a pristine surface finish is the most visible advantage, the true value of vacuum heat treatment lies in achieving absolute process control. By eliminating atmospheric variables, you gain unparalleled repeatability in producing the exact metallurgical properties required for high-performance applications.

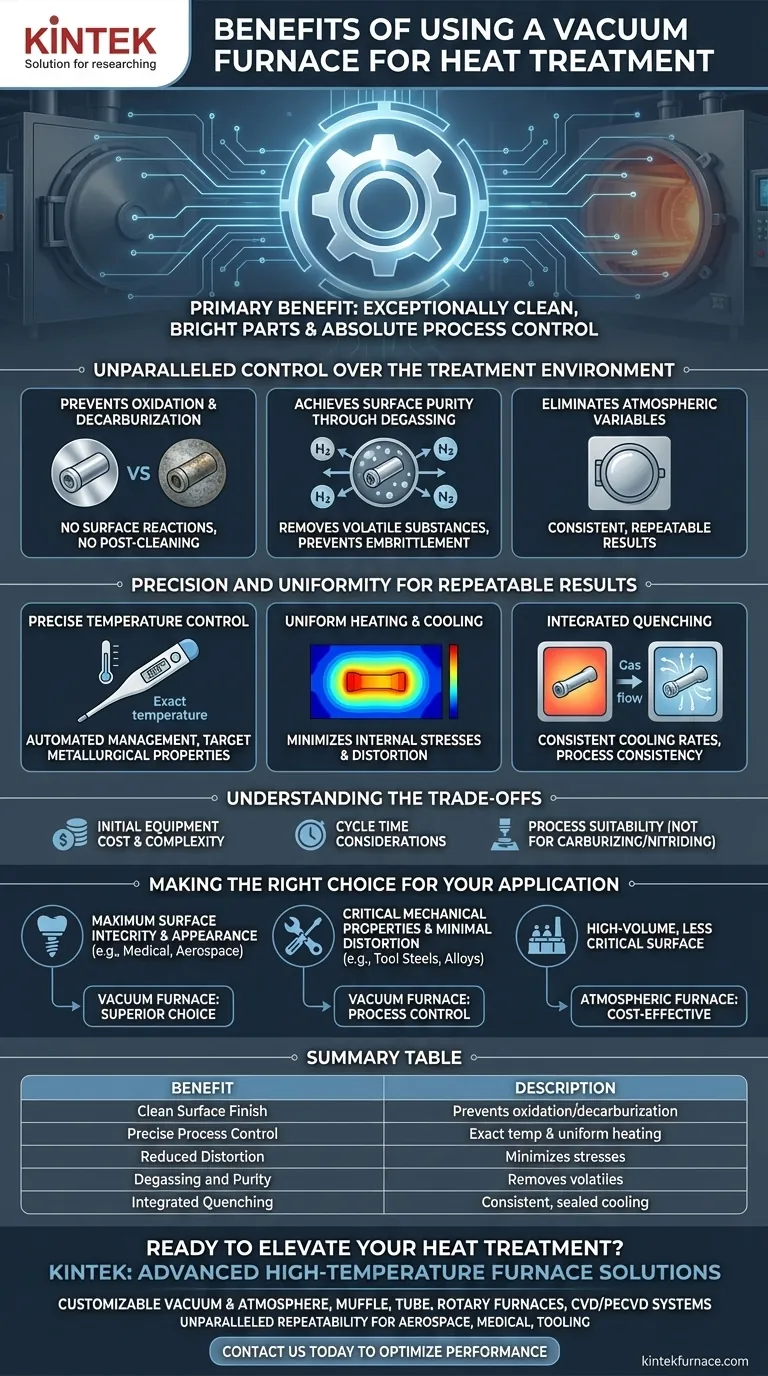

Unparalleled Control Over the Treatment Environment

The defining feature of a vacuum furnace is the removal of atmosphere. This seemingly simple act has profound implications for the quality and integrity of the heat-treated component.

Preventing Oxidation and Decarburization

At elevated temperatures, reactive gases like oxygen in the air will readily bond with a metal's surface, creating a layer of oxide scale. This discoloration must often be removed through costly and abrasive secondary operations.

A vacuum environment, by definition, removes virtually all oxygen. This fundamentally prevents oxidation, resulting in a clean, bright part directly out of the furnace.

Similarly, the controlled environment prevents decarburization—the loss of carbon from the surface of steel—which can compromise hardness and wear resistance.

Achieving Surface Purity Through Degassing

The vacuum actively pulls volatile substances and trapped gases, like hydrogen and nitrogen, out of the material itself. This degassing and degreasing function purifies the component's surface.

This is critical for preventing issues like hydrogen embrittlement, a failure mechanism that can severely compromise the integrity of high-strength steels.

Precision and Uniformity for Repeatable Results

Beyond creating a clean environment, vacuum furnaces provide a superior level of control over the entire thermal cycle, which is essential for achieving specific and repeatable mechanical properties.

Precise Temperature Control

Modern vacuum furnaces are equipped with advanced, automated process controls. This allows for extremely precise temperature management and uniform heating throughout the workload.

This level of precision is critical for hitting the exact temperatures required for metallurgical phase transformations, ensuring the material achieves its target hardness, toughness, and strength.

Uniform Heating and Cooling

By heating parts primarily through radiation in a vacuum, temperature gradients are minimized. This uniform heating reduces the internal stresses that cause distortion and warping, which is especially important for complex or thin-walled geometries.

The result is a higher pass rate for finished parts and less material wasted due to thermal deformation.

Integrated Quenching for Process Consistency

Many vacuum furnaces are all-in-one systems that include a sealed quenching chamber. After the heating cycle, the chamber is backfilled with a high-pressure inert gas (like nitrogen or argon) to cool the parts rapidly.

Keeping the entire process—from heating to quenching—within a single, sealed environment ensures a consistent, repeatable cooling rate and protects the part from contamination until it is at a safe temperature.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for every heat treatment need. Acknowledging its limitations is key to making an informed decision.

Initial Equipment Cost and Complexity

Vacuum furnaces represent a significant capital investment compared to traditional atmospheric furnaces. They require robust vacuum pumping systems and more complex control instrumentation, which also increases maintenance requirements.

Cycle Time Considerations

Achieving a deep vacuum takes time. The pump-down phase adds to the overall cycle time, which can make vacuum furnaces less suitable for high-volume, low-margin parts where throughput is the primary driver.

Process Suitability

For certain materials and processes where a specific surface reaction is desired (like carburizing or nitriding), an atmospheric furnace with a controlled carrier gas is necessary. A vacuum is beneficial only when the goal is to prevent all surface reactions.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on your end goal and the performance requirements of your component.

- If your primary focus is maximum surface integrity and appearance: A vacuum furnace is the superior choice for medical implants, aerospace components, and any part where a clean, bright finish is non-negotiable.

- If your primary focus is critical mechanical properties and minimal distortion: A vacuum furnace provides the process control needed for sensitive tool steels, high-performance alloys, and complex geometries.

- If your primary focus is high-volume production with less critical surface requirements: A traditional atmospheric furnace may offer a more cost-effective and higher-throughput solution.

Ultimately, choosing a vacuum furnace is an investment in process repeatability and the metallurgical purity of your final product.

Summary Table:

| Benefit | Description |

|---|---|

| Clean Surface Finish | Prevents oxidation and decarburization, eliminating need for post-treatment cleaning. |

| Precise Process Control | Enables exact temperature management and uniform heating for consistent metallurgical properties. |

| Reduced Distortion | Minimizes internal stresses and warping through uniform heating and cooling. |

| Degassing and Purity | Removes volatile substances to prevent issues like hydrogen embrittlement. |

| Integrated Quenching | Provides consistent cooling in a sealed environment for repeatable results. |

Ready to elevate your heat treatment process with precision and purity? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in aerospace, medical, or tooling industries, our vacuum furnaces deliver clean, bright parts with unparalleled repeatability. Contact us today to discuss how we can optimize your laboratory's performance and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today