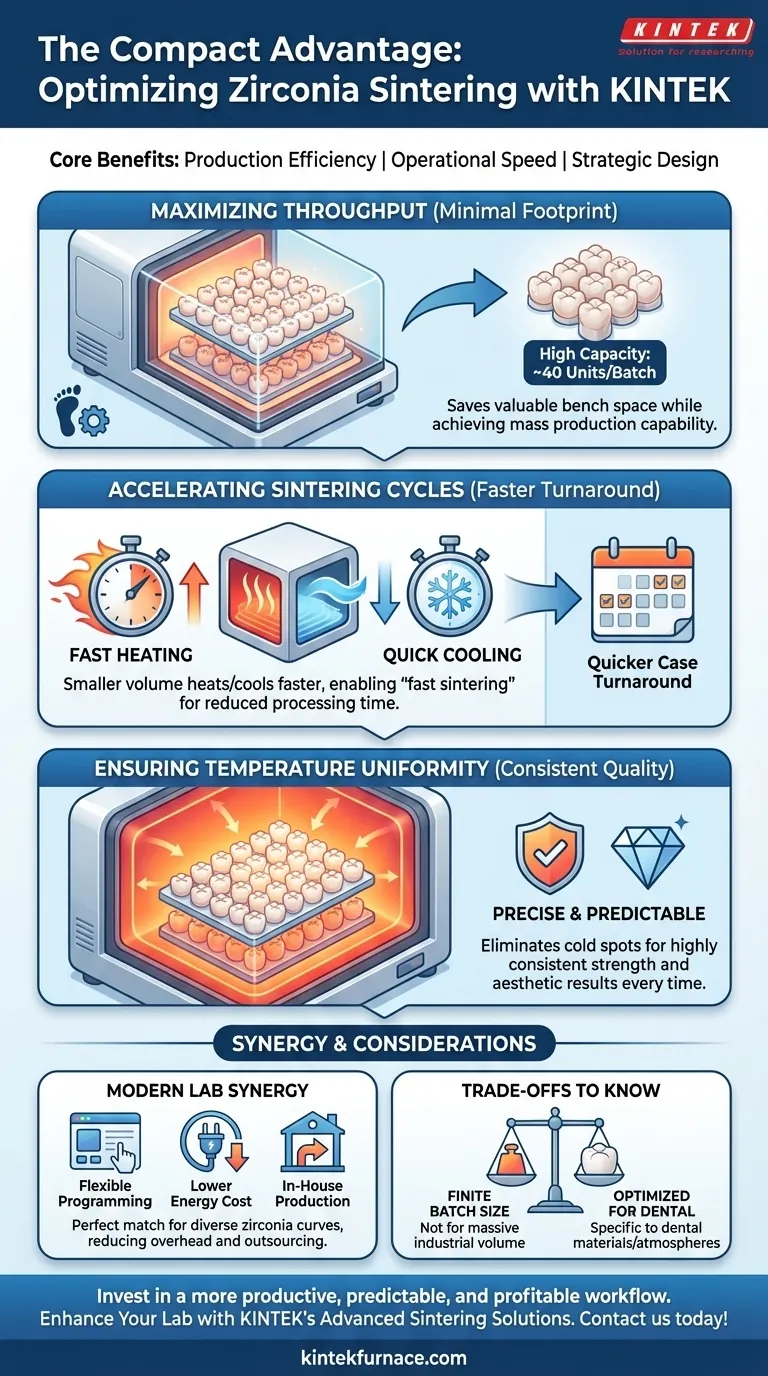

At its core, a compact furnace chamber in a Zirconia Dental Sintering Furnace is designed for two primary benefits: production efficiency and operational speed. Its smaller volume allows a dental lab to process a significant number of restorations (around 40 units) in a minimal physical footprint, while also enabling faster heating and cooling cycles.

The compact chamber is not just a space-saving feature; it is a strategic design choice that directly translates to higher throughput, faster turnaround times, and greater energy efficiency for dental laboratory and clinical workflows.

The Strategic Advantage of a Compact Design

A furnace chamber's size has a direct and significant impact on the entire sintering process. Understanding this relationship is key to appreciating its value beyond just the physical dimensions.

Maximizing Throughput in a Minimal Footprint

The most immediate benefit is placing high-capacity production into a small package. A chamber volume of around one liter is engineered to hold a multi-level tray system.

This design allows for the simultaneous sintering of approximately 40 individual dental units. For a dental lab, this means achieving mass production capability without sacrificing valuable bench space for a larger machine.

Accelerating Sintering Cycles

A smaller volume heats up and cools down much faster than a larger one. This physical principle is a critical advantage for modern dental materials.

The ability to achieve fast heating rates is essential for "fast sintering" cycles, drastically reducing the time required to process zirconia restorations. This improves overall lab productivity and enables quicker case turnaround.

Ensuring Temperature Uniformity

Achieving and maintaining a precise, uniform temperature throughout the chamber is critical for the final strength and aesthetic quality of the zirconia.

In a smaller, well-engineered chamber, it is easier to eliminate cold spots and ensure every restoration on every level receives the exact same heat treatment. This leads to highly consistent and predictable results.

Understanding the Trade-offs

While highly beneficial, the compact design comes with considerations that must be aligned with your specific operational needs.

Limitation on Batch Size

The capacity, while impressive for its size, is finite. A lab with extremely high volume may find a 40-unit batch restrictive, potentially requiring multiple furnaces to meet demand.

The design is optimized for the typical daily workflow of most labs and clinics, not necessarily for massive, centralized industrial production centers.

An Optimized, Not Universal, Solution

These furnaces are purpose-built for the sintering requirements of dental materials, primarily zirconia. The chamber's design and heating elements are optimized for these specific processes.

While programming is flexible, the physical constraints are tailored to dental restorations. It is not a general-purpose laboratory furnace for materials requiring vastly different atmospheres or physical dimensions.

How the Chamber Complements Modern Lab Needs

The compact chamber works in synergy with other furnace features to create a highly effective system for today's dental laboratories.

Synergy with Flexible Programming

Modern labs use many different types of zirconia, each with a unique, manufacturer-recommended sintering curve. The furnace's ability to store user-defined programs is a perfect match for the chamber's efficiency.

Technicians can load a batch and select the precise cycle required, ensuring both speed and material compliance. This combination of physical efficiency and digital flexibility is crucial.

Lowering Operational Costs

The benefits of a compact chamber directly contribute to a lower cost per unit. Faster cycles consume less electricity, and a smaller physical footprint reduces overhead.

Furthermore, by enabling labs to bring this process in-house, it eliminates the costs and delays associated with outsourcing to a third-party laboratory, improving both profitability and service quality.

Making the Right Choice for Your Lab

The decision to choose a furnace with a compact chamber depends on your primary objectives.

- If your primary focus is high-volume production: The combination of a 40-unit capacity and fast cycle times is ideal for maximizing daily throughput.

- If your primary focus is bringing production in-house: The small footprint and operational efficiency make it a practical choice for clinics and labs where space is a premium.

- If your primary focus is consistent quality: The superior temperature uniformity of a compact chamber helps ensure every restoration meets the highest standards for strength and fit.

Ultimately, integrating a furnace with a compact chamber is a direct investment in a more productive, predictable, and profitable workflow.

Summary Table:

| Benefit | Key Feature | Impact |

|---|---|---|

| Production Efficiency | Small footprint with 40-unit capacity | Maximizes throughput in minimal space |

| Operational Speed | Fast heating and cooling cycles | Reduces processing time for faster turnaround |

| Temperature Uniformity | Precise heat distribution | Ensures consistent quality and strength of restorations |

| Cost Savings | Lower energy consumption and overhead | Decreases operational costs per unit |

Ready to enhance your dental lab's productivity with advanced sintering solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces tailored for dental laboratories. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, combined with deep customization capabilities, precisely meet your unique experimental needs. Contact us today to discuss how our compact furnace chambers can boost your efficiency and profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations