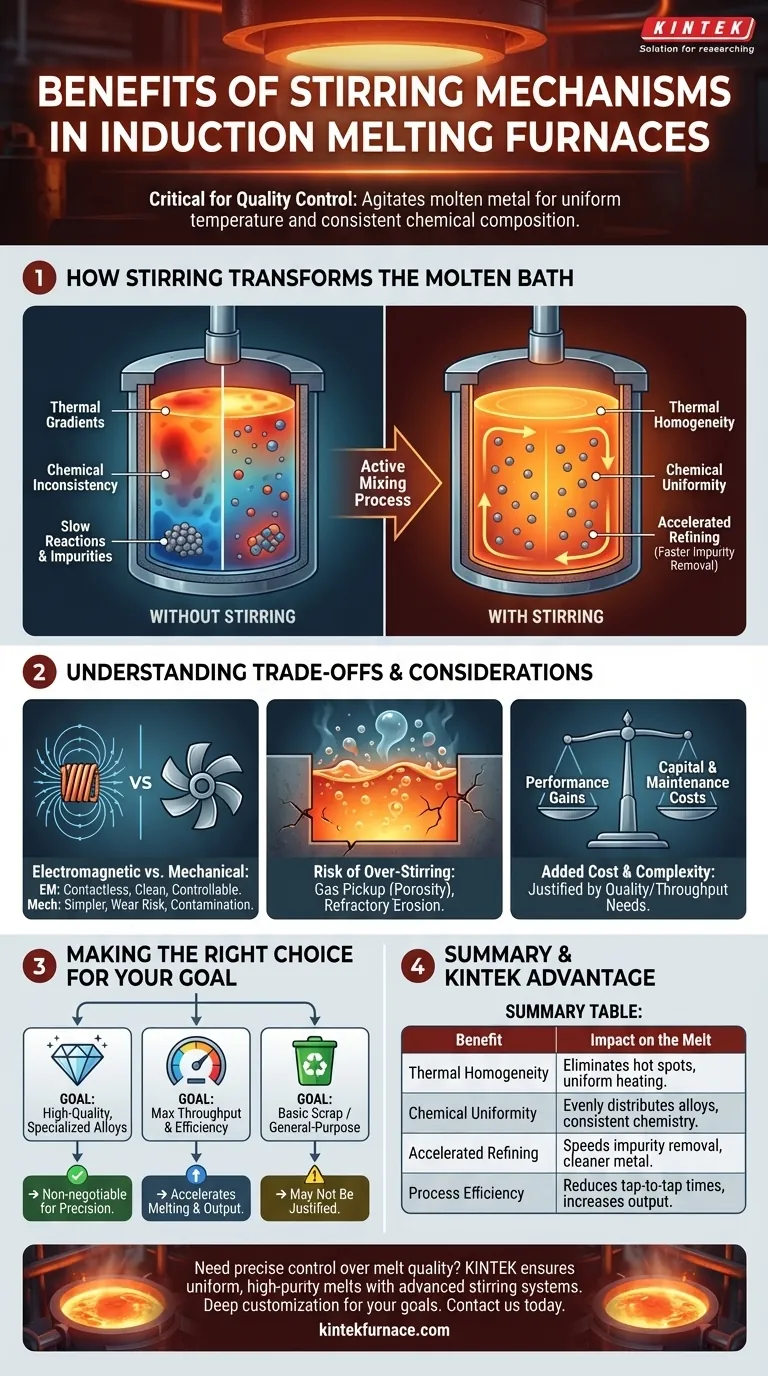

In essence, stirring mechanisms are critical for quality control in induction melting. They agitate the molten metal to ensure the final product has a uniform temperature and a consistent chemical composition. This active mixing process is key to removing impurities and creating a homogeneous, high-quality melt.

Stirring is not merely an auxiliary function; it is a core process that elevates induction melting from simple heating to precise metallurgical refinement. By actively managing the molten bath, you gain direct control over final material properties, consistency, and overall operational efficiency.

How Stirring Transforms the Molten Bath

An induction furnace melts metal with powerful magnetic fields, but this process can create inconsistencies within the molten bath. A stirring mechanism corrects these issues, ensuring a uniform and predictable result.

Achieving Thermal Homogeneity

Induction currents can create "hot spots" in the melt, leading to significant temperature variations. Stirring forces the circulation of the entire molten bath.

This circulation eliminates thermal gradients, ensuring the entire melt is at a single, uniform temperature. This prevents localized overheating, which can damage alloys, and avoids under-heated zones that can slow down the process.

Ensuring Chemical Uniformity

When adding alloys to a melt, they can easily become concentrated in one area. Without proper mixing, the final cast product will have inconsistent properties.

Stirring acts as a powerful, integrated mixer. It rapidly and evenly distributes all alloying elements throughout the molten metal, guaranteeing the final chemistry is consistent and meets precise specifications.

Accelerating Metallurgical Reactions

Refining metal involves reactions between the molten bath and slag to remove impurities. The speed of these reactions depends on the contact between the materials.

Stirring dramatically increases the surface area contact between the metal and slag, which accelerates the removal of oxides and other impurities. This results in cleaner metal and can significantly shorten overall cycle times.

Understanding the Trade-offs and Considerations

While highly beneficial, integrating a stirring mechanism is a decision that involves balancing performance gains with practical realities.

Electromagnetic vs. Mechanical Stirring

The two primary methods are electromagnetic and mechanical. Electromagnetic stirring uses low-frequency magnetic fields to induce movement without physical contact, offering clean and controllable operation.

Mechanical stirring uses a physical impeller, which is often simpler to implement but introduces a component that is subject to wear and can be a potential source of contamination if not managed correctly.

The Risk of Over-Stirring

More is not always better. Excessive or overly turbulent stirring can have negative consequences.

It can increase gas pickup from the atmosphere, leading to porosity defects in the final product. It can also accelerate the erosion of the furnace's refractory lining, increasing maintenance costs and downtime. The goal is always controlled, deliberate agitation.

Added Cost and Complexity

A dedicated stirring system adds to the initial capital cost of the furnace. It also introduces another layer of control and potential maintenance to the operation.

The decision to include one must be justified by the need for higher-quality alloys, improved consistency, or the throughput gains it enables.

Making the Right Choice for Your Goal

Ultimately, the need for a stirring mechanism depends entirely on your operational goals and the materials you produce.

- If your primary focus is producing high-quality, specialized alloys: A stirring mechanism is non-negotiable for achieving the required chemical homogeneity and cleanliness.

- If your primary focus is maximizing throughput and efficiency: Stirring accelerates melting and refining, reducing tap-to-tap times and increasing the overall output of your furnace.

- If your primary focus is melting basic scrap for general-purpose castings: The added cost of a stirring system may not be justified if minor variations in chemistry and temperature are acceptable.

By understanding your metallurgical requirements, you can determine if a stirring mechanism is a necessary tool for precision or an unnecessary complexity.

Summary Table:

| Benefit | Impact on the Melt |

|---|---|

| Thermal Homogeneity | Eliminates hot spots and temperature gradients for uniform heating. |

| Chemical Uniformity | Evenly distributes alloying elements for consistent final chemistry. |

| Accelerated Refining | Speeds up impurity removal by increasing metal-slag contact. |

| Process Efficiency | Reduces tap-to-tap times, increasing overall furnace throughput. |

Need precise control over your melt quality and efficiency? At KINTEK, we understand that achieving a uniform, high-purity melt is critical for producing advanced alloys. Our expertise in high-temperature furnace solutions, including advanced induction melting systems with precisely controlled stirring mechanisms, ensures you get the metallurgical results you demand. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to tailor a furnace solution that perfectly matches your specific material and production goals. Contact us today to discuss how we can enhance your melting process. Get in touch with our experts

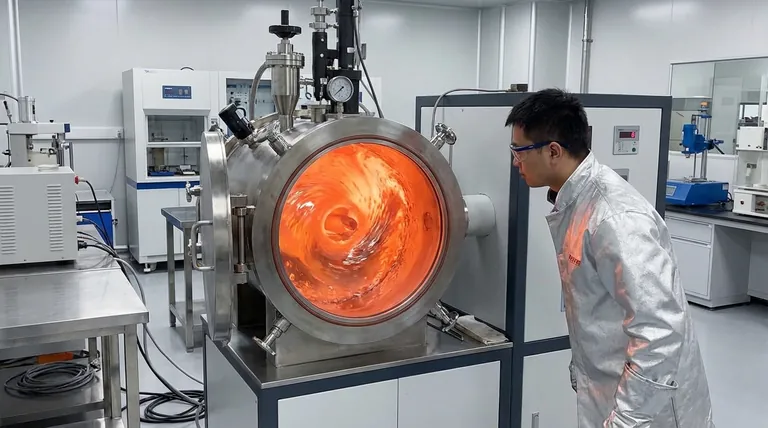

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a cooling system necessary in an induction heater? Prevent Overheating and Ensure Safe Operation

- What factors should be considered when selecting an induction melting furnace for a business? Maximize Efficiency and ROI

- What is the role of a Vacuum Arc Melting Furnace in HEA prep? Achieve Perfect Alloy Homogeneity

- What role does a vacuum induction melting furnace play in the K439B superalloy? Ensure High-Purity Casting Outcomes

- What are the key advantages of melting metals under vacuum or protective atmospheres? Achieve Purity and Precision in Metal Processing

- How does a vacuum induction furnace work? Achieve Ultra-Clean Metal Melting for Superior Alloys

- What components are involved in a vacuum system for induction furnaces? Optimize Your High-Temperature Processing

- What is the primary function of a Vacuum Arc Melting Furnace in the synthesis of Al25CoCrFeNiNd? Ensure Alloy Purity