In short, adopting electromagnetic heating in a rotary kiln delivers significant benefits in three core areas: thermal efficiency, process speed, and product quality. By generating heat directly within the material itself, this technology dramatically reduces energy waste, accelerates production cycles, and provides a level of temperature precision that traditional heating methods cannot match.

The primary advantage isn't just better heating; it's a fundamentally different approach. Unlike traditional methods that heat the kiln chamber and then transfer that heat to the material, electromagnetic induction generates heat directly within the material itself, leading to unprecedented efficiency and control.

How Electromagnetic Heating Redefines Kiln Performance

The benefits of electromagnetic (EM) heating stem from its unique physical principle, which moves beyond the limitations of conventional combustion or resistance heating.

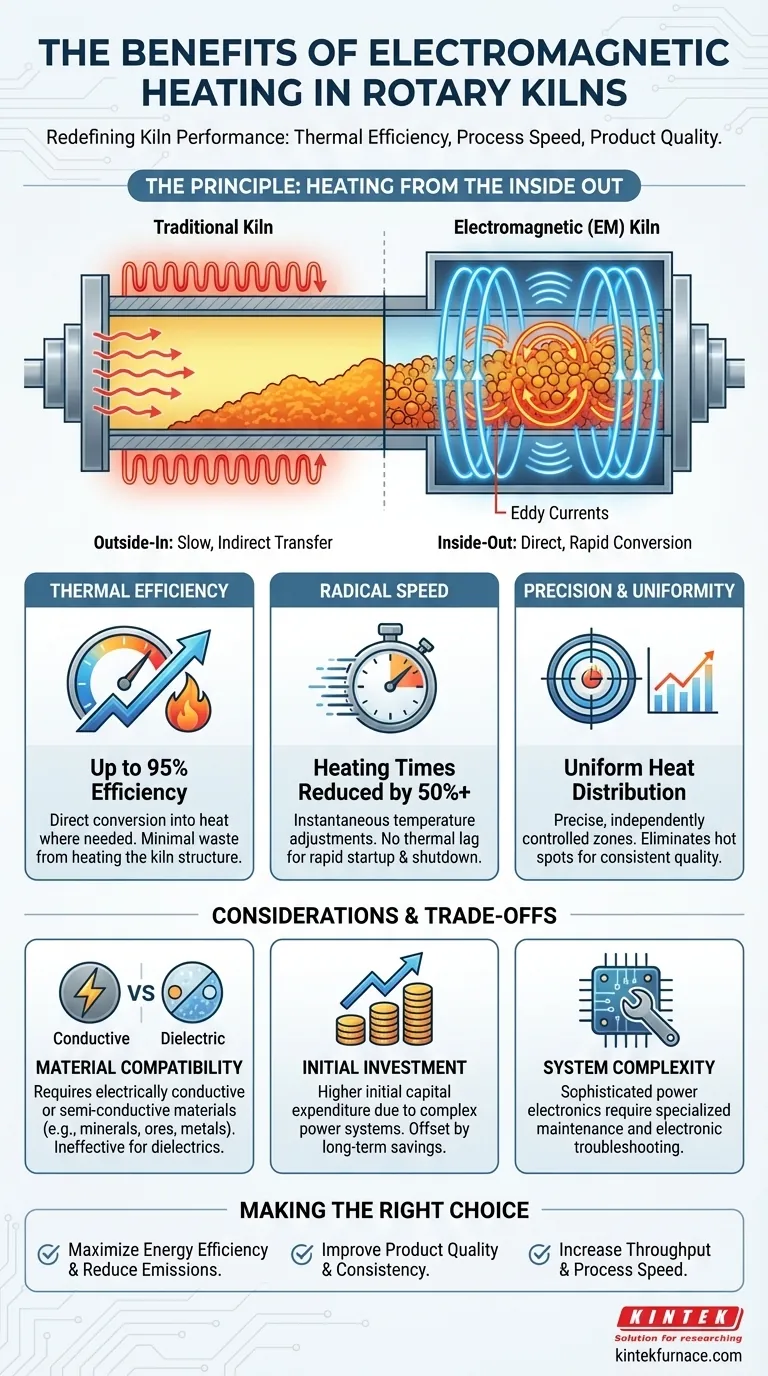

The Principle: Heating from the Inside Out

Traditional kilns heat from the outside in. They burn fuel or use heating elements to heat the kiln's internal atmosphere and walls, which then slowly transfer thermal energy to the material via radiation and conduction.

EM heating inverts this process. A high-frequency electromagnetic field is generated within the kiln, which induces electrical eddy currents directly inside the target material. These currents create heat through electrical resistance, effectively turning each particle of the material into its own tiny heat source.

Unprecedented Thermal Efficiency

Because energy is converted into heat precisely where it's needed—inside the material—very little is wasted. This direct conversion process can achieve thermal efficiencies of up to 95%.

Energy is not lost heating the massive volume of the kiln itself or escaping through exhaust flues, which is a major source of waste in conventional systems. This leads to a direct reduction in energy consumption and associated operational costs.

Radical Speed and Responsiveness

Heating the material directly eliminates the thermal lag inherent in conventional systems. You are no longer waiting for the kiln chamber to reach temperature and then for that heat to slowly penetrate the material bed.

As a result, heating times can be reduced by over 50%. Temperature adjustments are nearly instantaneous, allowing for rapid startup, shutdown, and precise control over the temperature profile throughout the calcination process.

Precision Control and Product Uniformity

The direct heating method ensures exceptionally uniform heat distribution throughout the material bed, avoiding the hot spots and cool zones common in traditional kilns.

Modern EM kilns can be designed with multiple, independently controlled temperature zones. This allows operators to create a precise thermal profile along the length of the kiln, ensuring the material experiences the exact required temperature for the exact required duration. This repeatability is critical for producing high-quality, consistent end products.

Understanding the Trade-offs and Considerations

While the benefits are substantial, electromagnetic heating is not a universal solution. A clear-eyed technical assessment requires understanding its limitations.

Material Compatibility is Key

The entire process relies on the ability to induce eddy currents within the material. This means the technology works best for materials that are electrically conductive or semi-conductive, such as certain minerals, ores, and metals.

For electrically insulating (dielectric) materials, this specific heating method would be ineffective. A thorough analysis of your material's properties is the essential first step.

Initial Capital Investment

The technology behind high-frequency power generation and induction coil systems is more complex than a simple gas burner. Consequently, the initial capital expenditure for an electromagnetic rotary kiln is typically higher than for a conventional system.

This upfront cost must be weighed against the significant long-term operational savings from reduced energy consumption, higher throughput, and potentially lower maintenance.

System Complexity

While the kilns are designed for a long service life, the underlying power electronics are more sophisticated than traditional heating equipment. Maintenance may require more specialized knowledge, and troubleshooting is an electronic rather than a mechanical process.

Making the Right Choice for Your Process

The decision to adopt electromagnetic heating should be driven by your specific production goals and material characteristics.

- If your primary focus is maximizing energy efficiency and reducing emissions: The direct, "inside-out" heating method offers efficiency up to 95%, drastically lowering long-term energy consumption.

- If your primary focus is improving product quality and consistency: The uniform, precisely zoned heating eliminates process variability and ensures every batch meets exact specifications.

- If your primary focus is increasing throughput and process speed: The ability to reduce heating times by more than half allows for significantly faster and more responsive production cycles.

Ultimately, adopting electromagnetic heating is a strategic shift from brute-force thermal processing to a precise, data-driven method of material transformation.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Thermal Efficiency | Up to 95% energy efficiency, reducing waste and operational costs |

| Process Speed | Heating times reduced by over 50%, with rapid startup and shutdown |

| Product Quality | Uniform heat distribution and precise temperature control for consistent results |

| Material Compatibility | Best for electrically conductive or semi-conductive materials |

Ready to transform your material processing with advanced electromagnetic heating? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and product quality—Get in touch now!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions