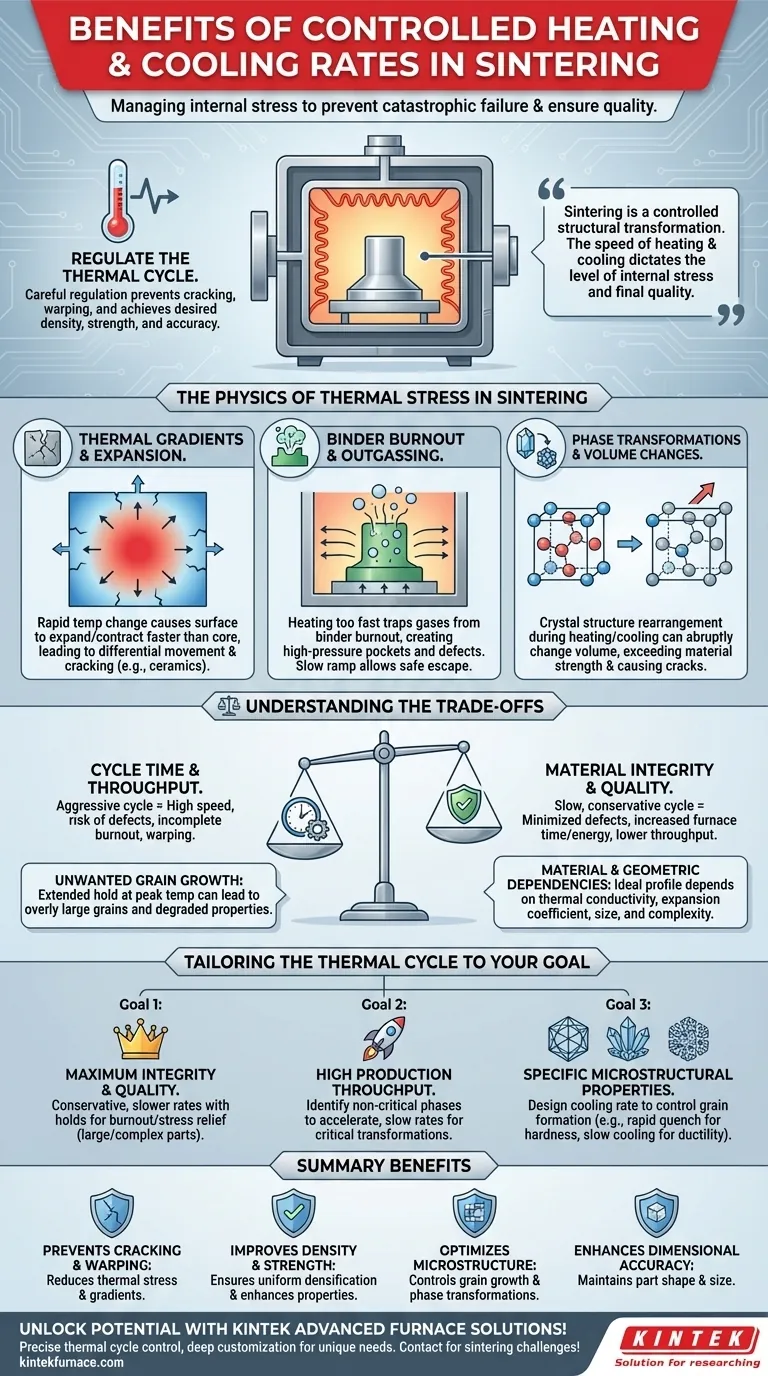

At its core, controlling the heating and cooling rates during sintering is the primary method for managing internal stress within a material. By carefully regulating the thermal cycle, you prevent catastrophic failures like cracking and warping, ensuring the sintered component achieves its desired density, strength, and dimensional accuracy.

Sintering is more than just a heating process; it's a controlled structural transformation. The speed at which you heat and cool the material dictates the level of internal stress it experiences, directly impacting the final quality and viability of the product.

The Physics of Thermal Stress in Sintering

Sintering success hinges on navigating the physical changes a material undergoes when heated and cooled. Rushing this process introduces immense stress that can easily destroy the component.

Thermal Gradients and Expansion

When a part is heated or cooled quickly, its surface changes temperature faster than its core. This difference, known as a thermal gradient, causes different parts of the material to expand or contract at different rates.

This differential movement creates powerful internal stresses. For brittle materials like ceramics, this stress is the most common cause of cracking.

Binder Burnout and Outgassing

Most powder metallurgy processes use an organic binder to hold the loose powder in its green state. This binder must be completely removed, or "burned out," at a relatively low temperature before densification begins.

Heating too rapidly can trap the gases produced during burnout, creating high-pressure pockets within the part. This can lead to internal pores, blisters, or even catastrophic failure. A slow, controlled heating ramp is essential to allow these gases to escape safely.

Phase Transformations and Volume Changes

As many materials, particularly alloys and certain ceramics, are heated and cooled, they undergo phase transformations. This is when their internal crystal structure rearranges.

These transformations are often accompanied by an abrupt change in volume. If this occurs too quickly across a thermal gradient, the resulting internal strain can easily exceed the material's strength, causing cracks or distortion.

Understanding the Trade-offs

While slow and steady is often the safest approach, it is not always the most efficient. The ideal thermal cycle is a balance between metallurgical precision and operational reality.

Cycle Time vs. Material Integrity

The most fundamental trade-off is speed versus quality. A slower, more conservative thermal cycle minimizes the risk of defects but increases furnace time, reduces throughput, and consumes more energy.

Conversely, an aggressive cycle that prioritizes speed dramatically increases the risk of thermal shock, incomplete binder burnout, and warping, leading to a higher scrap rate.

Unwanted Grain Growth

Holding a material at its peak sintering temperature for an extended period can lead to excessive grain growth. While densification is desired, overly large grains can sometimes degrade certain mechanical properties, such as fracture toughness.

The cooling rate also influences the final grain structure. Therefore, the entire thermal profile must be optimized not just to prevent cracks, but also to achieve the target microstructure.

Material and Geometric Dependencies

There is no universal "correct" rate. The ideal profile is highly dependent on the material's thermal conductivity, its coefficient of thermal expansion, the part's size, and its geometric complexity.

Large, thick parts or those with sharp angles are far more susceptible to thermal gradients and require significantly slower heating and cooling rates than small, simple components.

Tailoring the Thermal Cycle to Your Goal

Defining your primary objective is the first step toward optimizing your sintering process. The right thermal profile depends entirely on what you prioritize.

- If your primary focus is maximum structural integrity and quality: Use conservative, slower heating and cooling rates, with dedicated holds for binder burnout and stress relief, especially for large or complex parts.

- If your primary focus is high production throughput: Carefully identify the non-critical phases of the cycle where rates can be accelerated, and focus on slow, precise control only during critical phase transformations or binder burnout stages.

- If your primary focus is achieving specific microstructural properties: Design the cooling rate to control grain formation, as rapid quenching can create different, harder phases (like martensite in steel) while slow cooling promotes softer, more ductile structures.

Mastering the thermal cycle is the key to transforming loose powder into a reliable, high-performance component.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Cracking and Warping | Reduces thermal stress and gradients to avoid material failure and distortion. |

| Improves Density and Strength | Ensures uniform densification and enhances mechanical properties of sintered parts. |

| Optimizes Microstructure | Controls grain growth and phase transformations for targeted material characteristics. |

| Enhances Dimensional Accuracy | Maintains part shape and size by minimizing internal stresses during thermal cycles. |

Unlock the full potential of your sintering process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise thermal cycle control to meet your unique experimental needs, boosting efficiency and reducing defects. Contact us today to discuss how we can tailor a solution for your sintering challenges!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials