In short, vacuum brazing provides superior joint integrity and dimensional stability for aluminum components when compared to traditional welding. This is achieved by performing the joining process inside a vacuum, which prevents oxidation without requiring corrosive flux, and by heating the entire assembly uniformly to minimize heat-induced distortion.

The core difference is one of philosophy: welding is an intense, localized process that melts base materials together, while vacuum brazing is a holistic, controlled thermal process that joins components without melting them. This distinction makes vacuum brazing the definitive choice for high-precision, complex, or distortion-sensitive aluminum assemblies.

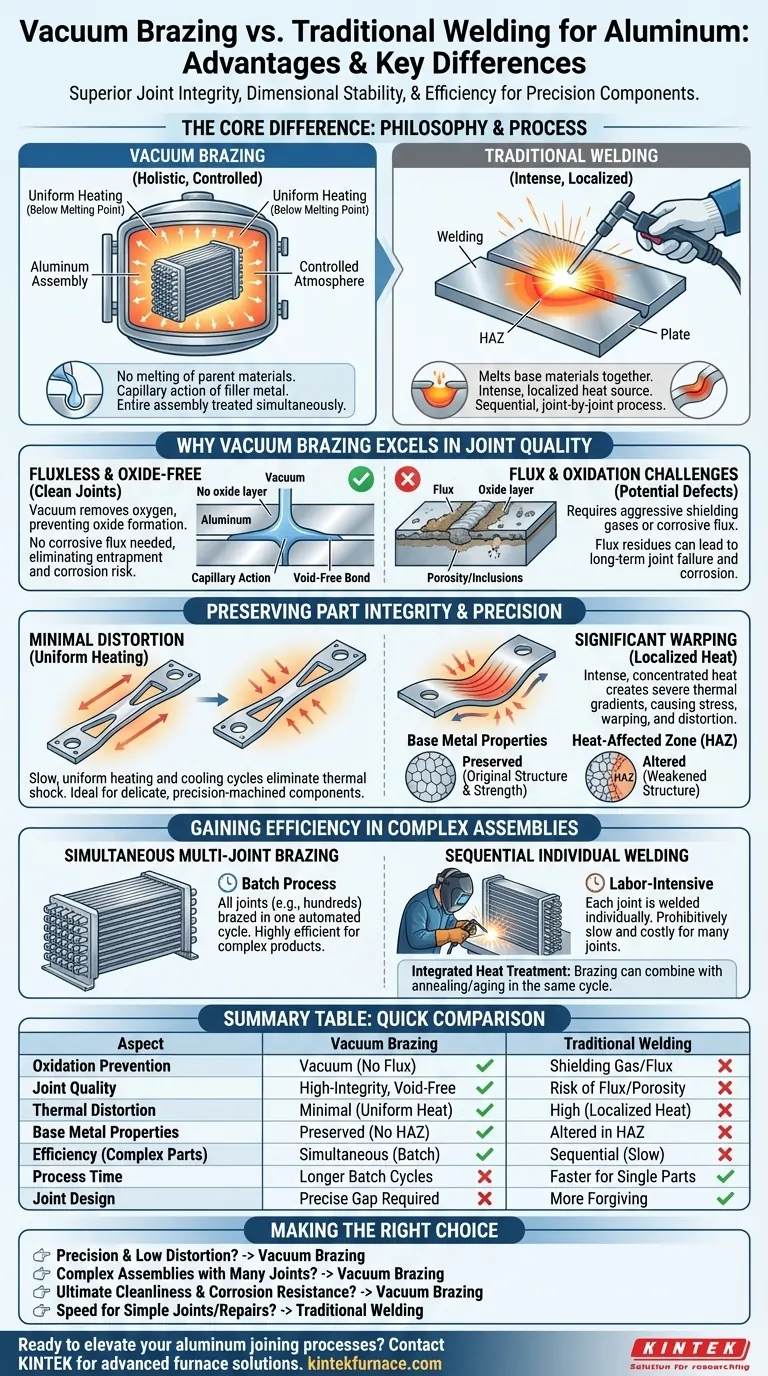

Why Vacuum Brazing Excels in Joint Quality

The primary challenge in joining aluminum is its immediate and tenacious oxide layer. Vacuum brazing directly solves this fundamental problem.

Eliminating Oxidation Without Flux

In a vacuum furnace, the oxygen is removed from the environment. This prevents the formation of aluminum oxide, which would otherwise inhibit the flow of filler metal and weaken the bond.

Traditional welding must aggressively combat this oxide layer using shielding gases (like in TIG/MIG) or chemical fluxes. These fluxes are corrosive and must be meticulously cleaned after welding to prevent long-term joint failure, adding an extra step and risk to the process.

Because vacuum brazing is a fluxless process, it produces exceptionally clean, strong joints that are free from the risk of flux entrapment or post-braze corrosion.

Achieving High-Integrity Bonds

In vacuum brazing, a filler metal with a lower melting point is placed at the joint. As the assembly is heated uniformly, this filler metal melts and is pulled into the tight gap between the parent components by capillary action.

This process ensures the entire joint interface is wetted, creating a strong, continuous, and void-free bond.

Preserving Part Integrity and Precision

For components where dimensional accuracy is critical, the method of heat application is paramount. Welding's localized heat is its biggest drawback in this regard.

Minimizing Thermal Distortion

Welding introduces intense, concentrated heat from an arc or flame. This creates severe thermal gradients across the part, causing stress that leads to warping and distortion.

Vacuum brazing, in contrast, heats the entire assembly slowly and uniformly inside a furnace. The subsequent cooling cycle is also precisely controlled. This lack of thermal shock virtually eliminates distortion, making it ideal for delicate or precision-machined components.

Maintaining Base Metal Properties

Welding functions by melting the parent materials together. This creates a Heat-Affected Zone (HAZ) where the base metal's crystalline structure and mechanical properties are altered, often in undesirable ways.

Vacuum brazing occurs at a temperature below the melting point of the aluminum components. The parent materials remain solid, preserving their original strength, temper, and metallurgical characteristics.

Gaining Efficiency in Complex Assemblies

While a single weld can be fast, vacuum brazing offers unparalleled efficiency for the right type of product.

Brazing Multiple Joints Simultaneously

For a complex assembly like a heat exchanger with hundreds of fins and tubes, welding each joint individually would be prohibitively slow and labor-intensive.

With vacuum brazing, the entire assembly can be prepared with filler metal and placed in the furnace. All joints—whether a dozen or a thousand—are brazed simultaneously in a single, automated cycle.

Integrating Heat Treatment

Since the component is already in a computer-controlled furnace, the heating and cooling cycle can be designed to serve a dual purpose.

The brazing cycle can be combined with a required heat treatment process, such as annealing or age hardening. This consolidation of manufacturing steps saves significant time, handling, and energy.

Understanding the Trade-offs

While powerful, vacuum brazing is not a universal solution. Understanding its limitations is key to making an informed decision.

Process Time and Batching

A vacuum furnace cycle is a long process, often taking several hours from start to finish. It is a batch process, making it inefficient for single-part production or quick repairs where welding would be much faster.

Joint Design and Gap Control

Vacuum brazing relies on capillary action, which requires a specific and consistent gap between the parts (typically 0.002 to 0.005 inches). This demands precise joint design and component manufacturing, as it is less forgiving of poor fit-up than welding.

Equipment and Cost

Vacuum furnaces represent a significant capital investment and require substantial infrastructure. This makes the process more suitable for established production environments than for small shops or prototyping, where the flexibility and low entry cost of welding are advantageous.

Making the Right Choice for Your Application

Your final decision should be driven by the non-negotiable requirements of your project.

- If your primary focus is precision and minimal distortion: Vacuum brazing is superior for delicate, thin-walled, or high-tolerance components due to its uniform heating.

- If your primary focus is joining complex assemblies with many joints: The ability to braze all joints simultaneously makes vacuum brazing highly efficient for products like heat exchangers or wave guides.

- If your primary focus is ultimate joint cleanliness and corrosion resistance: The fluxless nature of vacuum brazing provides the cleanest possible joint, eliminating the risk of residual flux corrosion.

- If your primary focus is speed for simple joints, repairs, or structural fabrication: Traditional welding methods are typically faster, more portable, and more forgiving of imperfect part fit-up.

By understanding these core differences, you can confidently select the joining process that aligns with your specific quality, efficiency, and design requirements.

Summary Table:

| Aspect | Vacuum Brazing | Traditional Welding |

|---|---|---|

| Oxidation Prevention | Uses vacuum environment, no flux | Requires shielding gases or corrosive flux |

| Joint Quality | High-integrity, void-free bonds via capillary action | Can have flux entrapment, risk of corrosion |

| Thermal Distortion | Minimal due to uniform heating | High due to localized heat, causing warping |

| Base Metal Properties | Preserved, no HAZ | Altered in Heat-Affected Zone (HAZ) |

| Efficiency for Complex Assemblies | Multiple joints brazed simultaneously | Joints welded individually, slower for many parts |

| Process Time | Longer batch cycles (hours) | Faster for single parts or repairs |

| Joint Design | Requires precise gap control (0.002-0.005 inches) | More forgiving of fit-up variations |

| Cost and Equipment | High capital investment for furnaces | Lower entry cost, more portable |

Ready to elevate your aluminum joining processes with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're working on high-precision components, complex assemblies, or demanding corrosion-resistant applications, our vacuum brazing expertise can help you achieve superior results. Contact us today to discuss how we can optimize your manufacturing workflow and deliver reliable, high-quality outcomes for your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum heat treatment equipment prevent the eggshell effect? Advanced Duplex Solutions for Surface Durability

- What are high temperature vacuum furnaces used for? Essential for Aerospace, Medical, and Electronics

- Why is a vacuum distillation apparatus necessary in the Kroll process? Achieving Purity in Zirconium Sponge Production

- What is the function of computer-controlled systems in modern vacuum furnaces? Achieve Unwavering Precision & Repeatability

- Why is a vacuum device essential for removing air bubbles within simulated scrap steel? Enhance Your Fluid Experiments

- What are the key benefits of using a vacuum furnace? Achieve Superior Material Purity and Control

- What role does an LTGN vacuum furnace play in stainless steel modification? Master S-Phase Surface Hardening

- What are the technical advantages of using a vacuum drying oven for electrocatalyst powders? Pt/HCCP Drying Guide