At its core, the advantage of a rotary tube furnace is its ability to dynamically mix materials during heating, a capability traditional static furnaces lack. This fundamental difference delivers superior temperature uniformity, process control, and efficiency, especially when working with powders, granules, or other particulate matter.

The decision between a rotary and static furnace is a choice between two distinct philosophies: static furnaces "bake" a stationary material, while rotary furnaces actively "process" a moving material. For any application where material consistency is paramount, this distinction is the most critical factor.

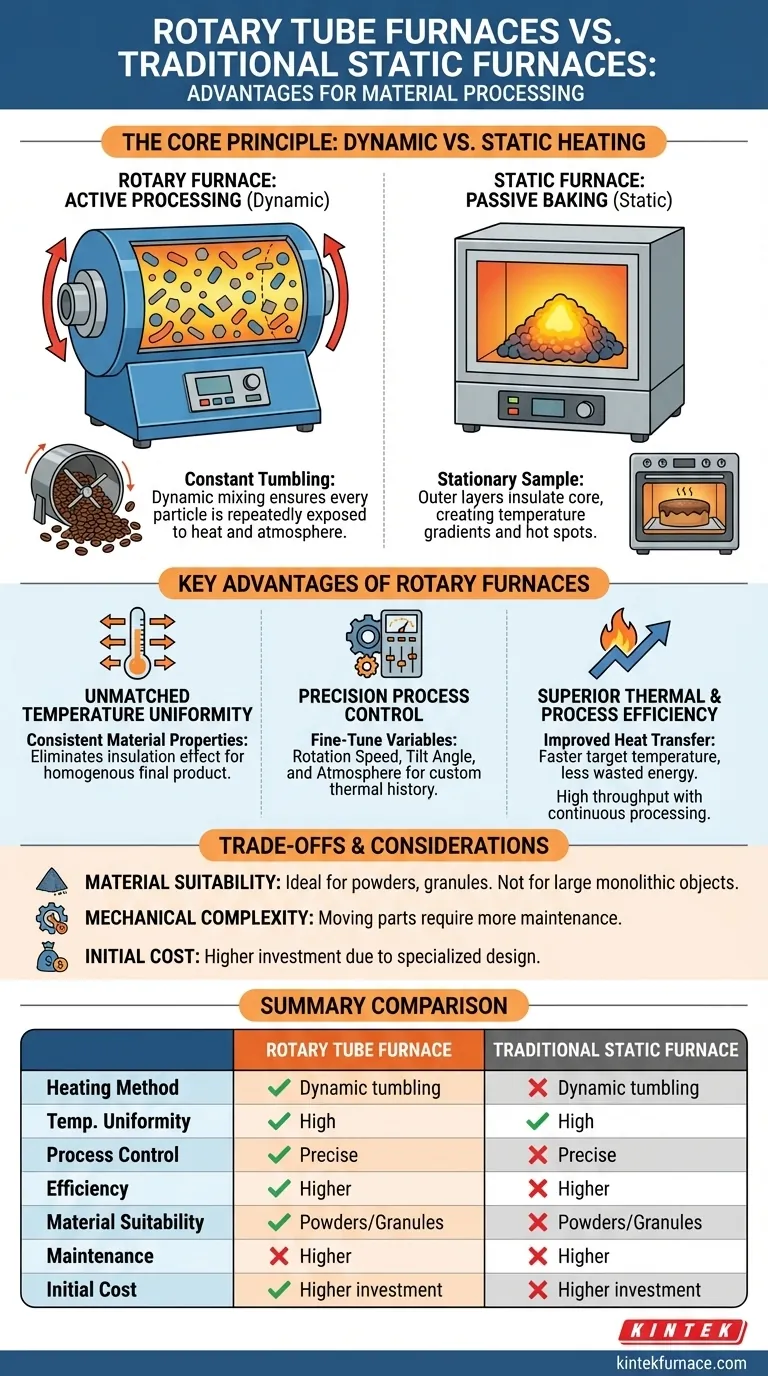

The Core Principle: Dynamic vs. Static Heating

The most significant limitations of traditional furnaces arise from their static nature. Rotary furnaces were engineered specifically to overcome these challenges through controlled movement.

How Static Furnaces Work (and Their Limits)

A traditional furnace, such as a box or static tube furnace, operates like a conventional oven. It heats a stationary sample through radiation and convection.

This method works well for solid, monolithic parts. However, when heating powders or granules, the outer layers can absorb most of the heat, effectively insulating the core and creating significant temperature gradients.

This leads to inconsistent material properties, hot spots on the surface, and potential agglomeration (clumping) of particles.

The Rotary Advantage: Constant Tumbling

A rotary tube furnace solves this by continuously rotating the tube that contains the material. This constant tumbling action ensures every particle is repeatedly exposed to the heat source and the controlled atmosphere.

Think of it as the difference between baking a cake (static) and roasting coffee beans (dynamic). The constant movement of the beans is essential for an even, uniform roast, which is precisely what a rotary furnace achieves for particulate materials.

Key Advantages of Rotary Furnaces Explained

The dynamic heating principle translates into several practical, high-impact advantages for researchers and manufacturers.

Unmatched Temperature Uniformity

By eliminating the insulation effect seen in static powders, the furnace achieves exceptional temperature uniformity throughout the entire batch.

This constant mixing prevents localized overheating and ensures every particle undergoes the same thermal history. The result is a highly consistent, homogenous final product, which is critical for advanced materials synthesis.

Precision Process Control

Rotary furnaces offer multiple variables for fine-tuning a thermal process, moving beyond simple temperature control.

- Rotation Speed: Controls how aggressively the material is mixed.

- Tilt Angle: Determines the residence time—how long the material spends in the hot zone in a continuous or semi-continuous setup.

- Atmosphere Control: Precision gas systems and sealed tubes allow for strict control over the processing atmosphere, vital for preventing oxidation or enabling specific chemical reactions.

Superior Thermal and Process Efficiency

The constant movement of material dramatically improves heat transfer, allowing the batch to reach the target temperature more quickly and with less wasted energy.

Furthermore, many rotary furnaces are designed for continuous or semi-continuous processing. This allows for a much higher throughput compared to the one-batch-at-a-time limitation of most static furnaces.

Understanding the Trade-offs and Considerations

While powerful, a rotary furnace is a specialized tool and not the universal solution for all heating applications.

Material Suitability

These furnaces are purpose-built for powders, granules, and other small particulates. They are not suitable for heat-treating large, single components or objects that could be damaged by the tumbling action.

Mechanical Complexity and Maintenance

The rotation mechanism, drive motor, and gas-tight rotating seals introduce mechanical complexity. These moving parts require more maintenance and present more potential points of failure than a simple static box furnace.

Initial Cost and Setup

Due to their specialized design and mechanical components, rotary tube furnaces typically represent a higher initial investment than static furnaces of a similar size and temperature range.

Making the Right Choice for Your Process

Selecting the correct furnace requires a clear understanding of your material, your process goals, and your operational constraints.

- If your primary focus is ultimate material consistency for powders/granules: A rotary tube furnace is the superior choice for its unmatched uniformity.

- If your primary focus is high-throughput, continuous processing: The design of a tilting rotary furnace is built specifically for this, far outperforming static batch systems.

- If your primary focus is simple heat treatment of solid, monolithic objects: A traditional static furnace is more practical, cost-effective, and easier to maintain.

- If your primary focus is process development on a limited budget: A standard static tube furnace may be a more sensible starting point for basic proof-of-concept work.

Ultimately, choosing the right furnace depends on whether you are simply heating a material or engineering a precise thermal process.

Summary Table:

| Feature | Rotary Tube Furnace | Traditional Static Furnace |

|---|---|---|

| Heating Method | Dynamic tumbling for uniform exposure | Static heating, prone to gradients |

| Temperature Uniformity | High, due to constant mixing | Lower, with risk of hot spots |

| Process Control | Precise control over rotation speed, tilt angle, atmosphere | Limited to temperature and atmosphere |

| Efficiency | Higher thermal and process efficiency, suitable for continuous operation | Lower, typically batch-based |

| Material Suitability | Ideal for powders, granules, particulates | Best for solid, monolithic objects |

| Maintenance | Higher due to mechanical complexity | Lower, simpler design |

| Initial Cost | Higher investment | More cost-effective |

Ready to enhance your lab's material processing with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're working with powders, granules, or other materials, our expertise ensures superior temperature uniformity and process control. Contact us today to discuss how we can optimize your thermal processes and drive your research forward!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating