In high-demand thermal processing, ceramic tubes provide two decisive advantages over metal alloys for rotary furnaces: superior stability at extreme temperatures and exceptional chemical inertness. This combination is essential for advanced applications where process temperatures exceed the limits of alloys or where any risk of metallic contamination would compromise the final product.

The choice of tube material is what defines the operational limits and chemical purity of a rotary furnace. Ceramic tubes are the definitive solution for processes requiring extreme heat and absolute inertness, while metal alloys remain suitable for lower-temperature, less chemically sensitive applications.

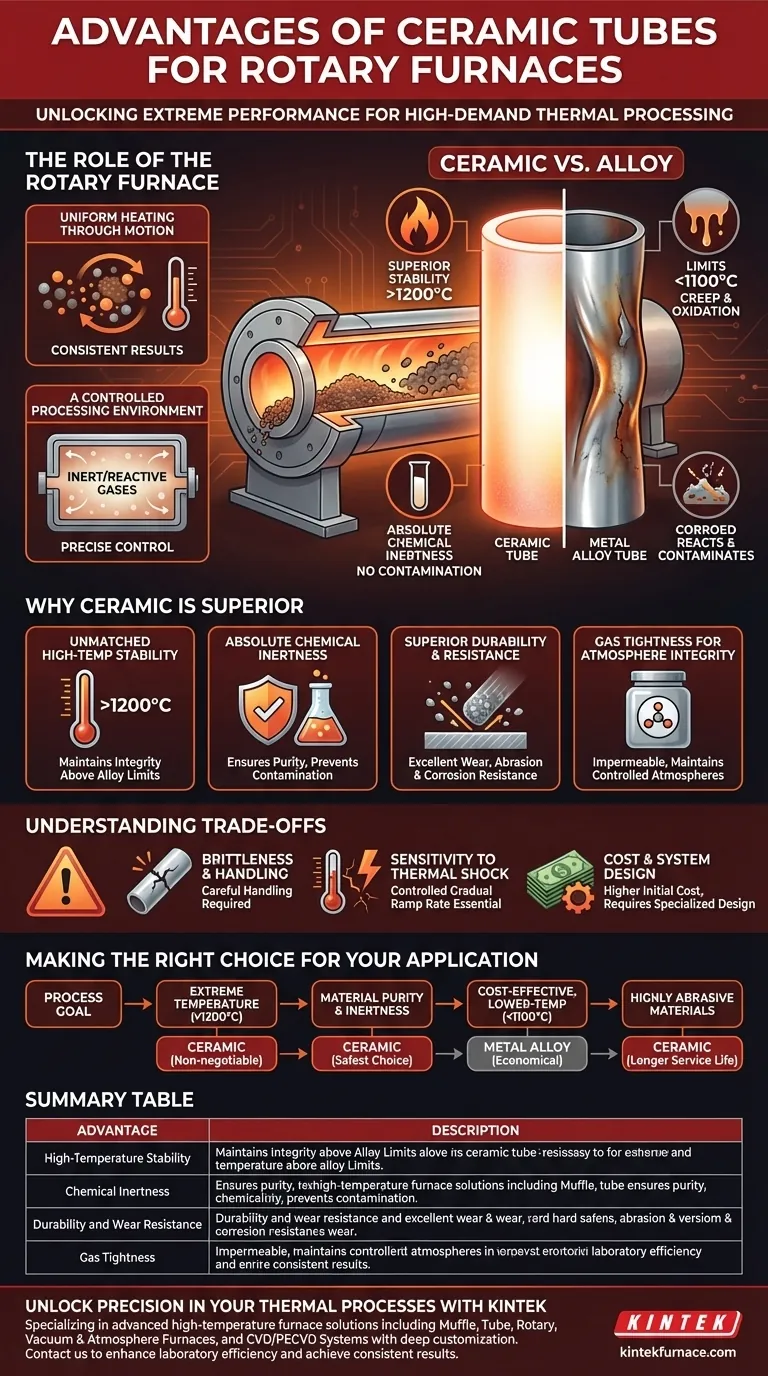

The Role of the Rotary Furnace

A rotary tube furnace is designed for the continuous or batch processing of powders and granular materials. Understanding its core function is key to appreciating why the tube material is so critical.

Uniform Heating Through Motion

The defining feature of this furnace is its rotating, cylindrical tube. This constant rotation tumbles the material, ensuring every particle is uniformly exposed to the heat source.

This method of indirect heat transfer is highly efficient and prevents hot spots, leading to consistent and reproducible results.

A Controlled Processing Environment

These furnaces provide a sealed environment, allowing for precise control over the processing atmosphere. This is critical for applications like calcination, pyrolysis, or synthesis that require inert (e.g., nitrogen, argon) or reactive gas environments.

Why Ceramic is the Superior Choice for Demanding Applications

When process conditions become extreme, the advantages of ceramic become non-negotiable. It excels where metal alloys begin to fail.

Unmatched High-Temperature Stability

Ceramic materials, particularly alumina, maintain their structural integrity at temperatures well above the melting or degradation points of even high-performance metal alloys.

They are necessary for any application requiring sustained temperatures above 1100-1200°C, a range where most alloys lose strength and begin to creep or oxidize.

Absolute Chemical Inertness

This is arguably the most critical advantage for high-purity applications. Metal alloy tubes can react with the processed material or the off-gases produced during heating.

This reaction can contaminate the product or degrade the tube itself. Ceramic is chemically inert, ensuring that the only reactions occurring are the ones you intend.

Superior Durability and Resistance

Ceramic offers excellent resistance to a wide range of hostile conditions common in industrial environments.

Its high hardness provides exceptional wear and abrasion resistance, making it ideal for processing abrasive powders that would quickly erode a metal tube. It also exhibits strong corrosion resistance.

Gas Tightness for Atmosphere Integrity

High-density ceramic tubes are impermeable to gases. This "gas tight" property is crucial for maintaining a pure, controlled atmosphere inside the furnace, preventing oxygen leaks or loss of process gases.

Understanding the Trade-offs: Ceramic vs. Alloy

While ceramic is superior for extreme conditions, it is not the default choice for every application. Its properties come with practical trade-offs that must be considered.

Brittleness and Handling

The primary drawback of ceramic is its brittleness. Unlike ductile metals that can deform under stress, ceramic will fracture. The tubes require careful handling during installation and maintenance to avoid chipping or cracking.

Sensitivity to Thermal Shock

This brittleness also makes ceramic tubes more susceptible to thermal shock. Heating or cooling the furnace too rapidly can create internal stresses that lead to cracks. A controlled, gradual temperature ramp rate is essential for ensuring a long service life.

Cost and System Design

Ceramic tubes are typically more expensive than their common alloy counterparts. Their installation and support system within the furnace may also require a more careful design to accommodate their rigidity and prevent stress points.

Making the Right Choice for Your Application

The decision between ceramic and alloy tubes must be driven by your specific process goals and operational window.

- If your primary focus is extreme temperature processing (>1200°C): Ceramic is non-negotiable, as standard metal alloys are not viable at these temperatures.

- If your primary focus is material purity and inertness: Ceramic is the safest choice to eliminate any risk of metallic contamination from the tube.

- If your primary focus is cost-effective, lower-temperature processing (<1100°C): A suitable metal alloy tube is often a more robust and economical solution, as it is less sensitive to handling and thermal shock.

- If you are processing highly abrasive materials: The superior wear resistance of ceramic can provide a longer service life and better long-term value, even at moderate temperatures.

By understanding these fundamental material properties, you can confidently select the tube that ensures the integrity and success of your thermal processing.

Summary Table:

| Advantage | Description |

|---|---|

| High-Temperature Stability | Maintains integrity above 1200°C, surpassing metal alloy limits. |

| Chemical Inertness | Prevents contamination and ensures purity in sensitive processes. |

| Durability and Wear Resistance | Resists abrasion and corrosion for longer service life. |

| Gas Tightness | Impermeable to gases, maintaining controlled atmospheres effectively. |

| Trade-offs | Brittleness, thermal shock sensitivity, and higher cost compared to alloys. |

Unlock Precision in Your Thermal Processes with KINTEK

Struggling with high-temperature challenges or contamination issues in your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization capabilities. Whether you're processing powders, granules, or require extreme heat and purity, our ceramic tube solutions ensure superior performance and reliability.

Contact us today to discuss how we can enhance your laboratory's efficiency and achieve consistent, reproducible results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing