At their core, advanced muffle furnaces are defined by specifications that deliver precise temperature control, robust safety features, and high energy efficiency. Key technical features include maximum operating temperatures typically ranging from 1200°C to 1700°C, high-purity fibrous alumina insulation, and sophisticated PID controllers with multi-segment programming for automating complex thermal cycles.

The key to understanding advanced muffle furnaces is recognizing that individual specifications work together as a system. It's the integration of precise control, superior insulation, and specialized atmosphere options that enables repeatable, high-purity results for demanding applications.

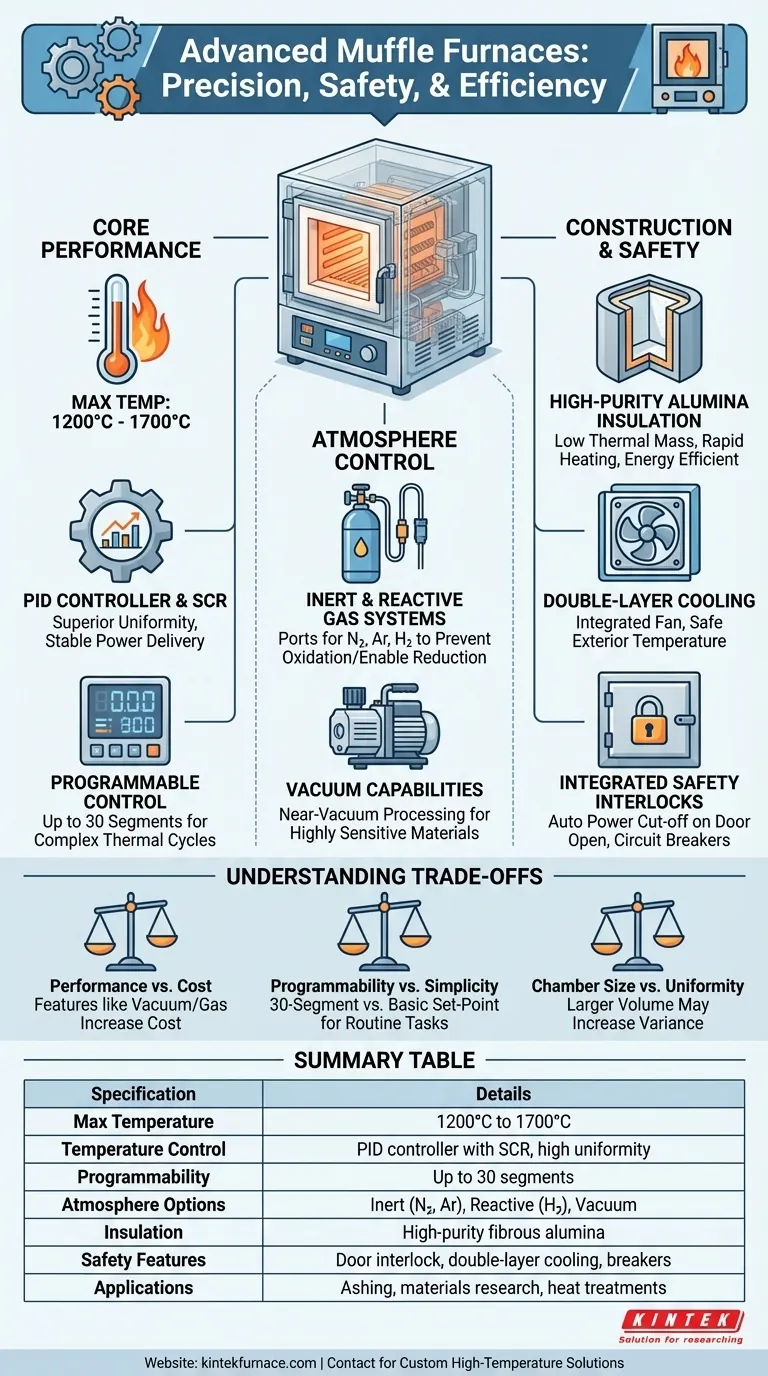

Core Performance Specifications

The primary function of any furnace is to generate and maintain heat. In advanced models, the specifications are geared toward achieving this with exceptional precision and reliability.

Maximum Operating Temperature

Modern muffle furnaces can achieve maximum temperatures between 1200°C and 1700°C, with some capable of even higher ranges. This specification is the first filter for determining if a furnace is suitable for a given process, such as ashing, materials research, or specific heat treatments.

Temperature Control and Uniformity

This is arguably the most critical feature of an advanced furnace. It is governed by a PID (Proportional-Integral-Derivative) controller, which ensures the temperature remains stable without overshooting the target.

This control is often managed via an SCR (Silicon Controlled Rectifier) or current limiting phase angle, allowing for smooth power delivery to the heating elements. The result is superior temperature uniformity across the entire chamber.

Programmable Control

Advanced furnaces feature programmable controllers with up to 30 segments. This allows users to design and automate complex heating profiles, with precise ramps, soaks (holding at a temperature), and cooling steps.

Advanced Atmosphere Control

A key differentiator for advanced furnaces is the ability to control the gaseous environment within the chamber. This is crucial for preventing unwanted chemical reactions like oxidation.

Inert and Reactive Gas Systems

Many models feature ports and control systems to introduce gases like nitrogen or argon to create an inert atmosphere. Others allow for reactive gases like hydrogen to perform reduction processes.

Vacuum Capabilities

For highly oxidation-sensitive materials, some furnaces are equipped with vacuum pump systems. This allows for processing in a near-vacuum, offering the highest level of protection against atmospheric contamination.

Construction and Safety Features

The physical design of an advanced muffle furnace is engineered for energy efficiency, durability, and operator safety.

High-Purity Alumina Insulation

The chamber is lined with high-purity fibrous alumina insulation. This material has low thermal mass and excellent insulating properties, enabling rapid heating cycles and minimizing energy loss.

Double-Layer Cooling Structure

The exterior consists of a double-layer steel structure with an integrated air cooling fan. This design actively dissipates heat, ensuring the outer casing remains at a safe temperature for operators.

Integrated Safety Interlocks

A non-negotiable feature is a safety interlock on the furnace door. This mechanism automatically cuts power to the heating elements when the door is opened, preventing exposure to extreme temperatures and ensuring operator safety. Further protection is provided by circuit breakers for emergency shutdowns.

Muffle Chamber Design

The term "muffle" refers to the inner chamber, typically made of a high-purity ceramic. This design isolates the workpiece from direct contact with the heating elements and any potential contaminants from combustion, ensuring a clean processing environment.

Understanding the Trade-offs

While advanced features offer greater capability, they also introduce complexities and considerations that must be weighed.

Performance vs. Cost

Features like vacuum systems, advanced gas mixing, and ultra-high temperature capabilities significantly increase the cost and complexity of a furnace. It is critical to assess whether these features are truly necessary for your application.

Programmability vs. Simplicity

A 30-segment programmable controller is extremely powerful for research and development. However, for simple, repetitive production tasks, a basic set-point controller may be more user-friendly and efficient.

Chamber Size vs. Temperature Uniformity

As the internal volume of a furnace increases, achieving perfect temperature uniformity becomes more challenging and expensive. A larger chamber may exhibit slightly greater temperature variance from corner to corner compared to a smaller, more compact model.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its technical specifications to your primary goal.

- If your primary focus is precision research and development: Prioritize a furnace with multi-segment programmability, superior PID control, and excellent temperature uniformity.

- If your primary focus is processing sensitive materials: Atmosphere control is non-negotiable; you must choose a model with vacuum or inert gas capabilities.

- If your primary focus is high-throughput quality control or ashing: Look for robust construction, rapid heating/cooling cycles, and simple, reliable safety features.

Ultimately, choosing the right furnace is about aligning its technical capabilities with the specific demands of your scientific or industrial process.

Summary Table:

| Specification | Details |

|---|---|

| Maximum Temperature | 1200°C to 1700°C |

| Temperature Control | PID controller with SCR, high uniformity |

| Programmability | Up to 30 segments for complex cycles |

| Atmosphere Options | Inert gases (N2, Ar), reactive gases (H2), vacuum systems |

| Insulation | High-purity fibrous alumina for efficiency |

| Safety Features | Door interlock, double-layer cooling, circuit breakers |

| Applications | Ashing, materials research, heat treatments |

Ready to elevate your laboratory's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior performance, safety, and efficiency. Don't settle for less—contact us today to discuss how we can support your specific applications and drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production