At their core, rotary kilns are the industrial workhorses for high-temperature material processing. Their most common applications are in the production of cement, the calcination of lime, and various metallurgical operations for extracting metals from ores. They achieve this by creating a controlled, high-temperature environment to induce specific chemical reactions or physical changes in a wide range of raw materials.

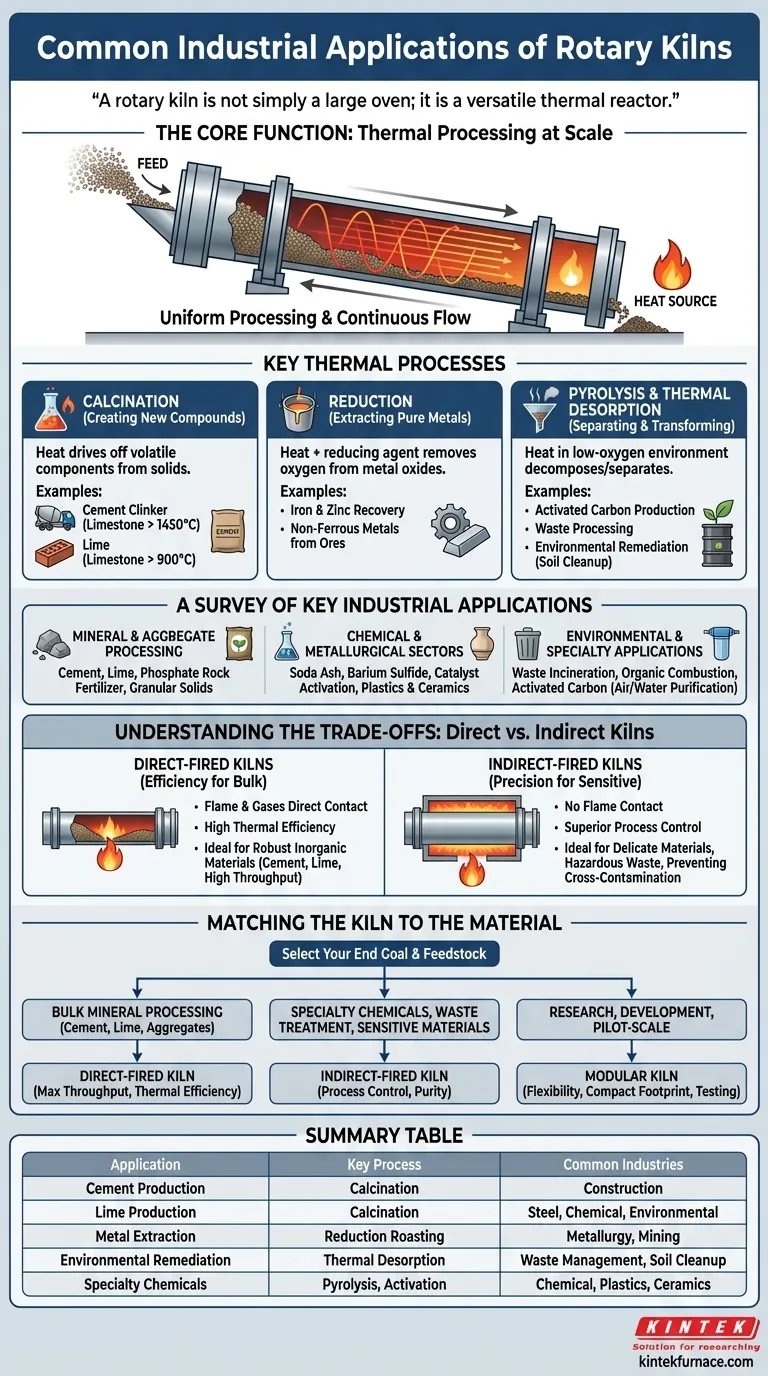

A rotary kiln is not simply a large oven; it is a versatile thermal reactor. Its value lies in its ability to continuously process vast quantities of material at extreme temperatures, making it an indispensable tool for industries that need to chemically or physically transform bulk solids at scale.

The Core Function: Thermal Processing at Scale

A rotary kiln is a large, rotating, and slightly inclined cylinder. Material is fed into the higher end, and as the kiln rotates, the material tumbles and mixes its way down toward the heat source at the lower end, ensuring uniform processing. This fundamental design enables several key thermal processes.

Calcination: Creating New Compounds

Calcination is a process that uses heat to drive off a volatile component from a solid, creating a new substance. This is the most prevalent use for rotary kilns.

The production of cement clinker is the quintessential example. Limestone (calcium carbonate) and other minerals are heated to over 1450°C, driving off carbon dioxide and causing a chemical reaction that forms the clinker nodules, which are then ground to make cement.

Similarly, lime (calcium oxide) is produced by heating limestone to a lower temperature (around 900°C) to drive off CO2.

Reduction: Extracting Pure Metals

In metallurgy, rotary kilns are used for reduction roasting. This process uses heat and a reducing agent to remove oxygen from metal oxides, liberating the pure metal.

This is a critical step in recovering metals like iron, zinc, and other non-ferrous metals from their respective ores.

Pyrolysis and Thermal Desorption: Separating and Transforming

These processes use heat in a low-oxygen or oxygen-free environment. Pyrolysis thermally decomposes organic materials, a method used to produce activated carbon or process certain types of waste.

Thermal desorption is used to drive off volatile contaminants from a solid substrate, such as removing mercury from soil or hydrocarbons from industrial waste. This makes it a key technology in environmental remediation.

A Survey of Key Industrial Applications

Beyond the "big three" of cement, lime, and metals, the rotary kiln's versatility extends into numerous specialized sectors.

Mineral and Aggregate Processing

This is the kiln's largest domain. It includes the aforementioned cement and lime production. It also extends to upgrading phosphate rock into phosphate fertilizer and processing various other small, granular solids and waste stones into usable products.

Chemical and Metallurgical Sectors

Rotary kilns are used to produce commodity chemicals like soda ash and barium sulfide. They are also essential for activating catalysts used in chemical manufacturing and for processing various materials in the plastics and ceramics industries.

Environmental and Specialty Applications

The environmental sector relies on kilns for waste incineration, organic combustion, and the remediation of contaminated soils. A growing application is the production and reactivation of activated carbon, which is critical for air and water purification systems worldwide.

Understanding the Trade-offs: Direct vs. Indirect Kilns

The choice of kiln design is dictated by the material being processed and the desired outcome. The primary distinction is how the material is heated.

Direct-Fired Kilns: Efficiency for Bulk Materials

In a direct-fired kiln, the flame and combustion gases are in direct contact with the process material. This is the most thermally efficient design.

This approach is ideal for robust, inorganic materials like cement and lime where high throughput is paramount and direct contact with combustion byproducts is not a concern.

Indirect-Fired Kilns: Precision for Sensitive Materials

In an indirect-fired kiln, the rotating cylinder is enclosed in an external furnace or heated by internal tubes. The material never comes into contact with the flame or combustion gases.

This design is essential when processing delicate materials, treating hazardous waste, or when cross-contamination would ruin the final product. It offers superior process control at the cost of lower thermal efficiency.

Matching the Kiln to the Material

Selecting the right thermal processing technology depends entirely on your end goal and feedstock.

- If your primary focus is bulk mineral processing (cement, lime, aggregates): You need maximum throughput and thermal efficiency, making a direct-fired kiln the standard choice.

- If your primary focus is specialty chemicals, waste treatment, or sensitive materials: You must prioritize process control and purity, making an indirect-fired kiln the necessary solution.

- If your primary focus is research, development, or pilot-scale production: A smaller, modular kiln offers the flexibility and compact footprint needed to test processes before scaling up.

The rotary kiln's simple design, robust construction, and operational flexibility have secured its place as a foundational technology in modern industry.

Summary Table:

| Application | Key Process | Common Industries |

|---|---|---|

| Cement Production | Calcination | Construction, Building Materials |

| Lime Production | Calcination | Steel, Chemical, Environmental |

| Metal Extraction | Reduction Roasting | Metallurgy, Mining |

| Environmental Remediation | Thermal Desorption | Waste Management, Soil Cleanup |

| Specialty Chemicals | Pyrolysis, Activation | Chemical, Plastics, Ceramics |

Unlock the full potential of your industrial processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with rotary kilns and other systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs. Contact us today to discuss how we can enhance your efficiency and outcomes!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource