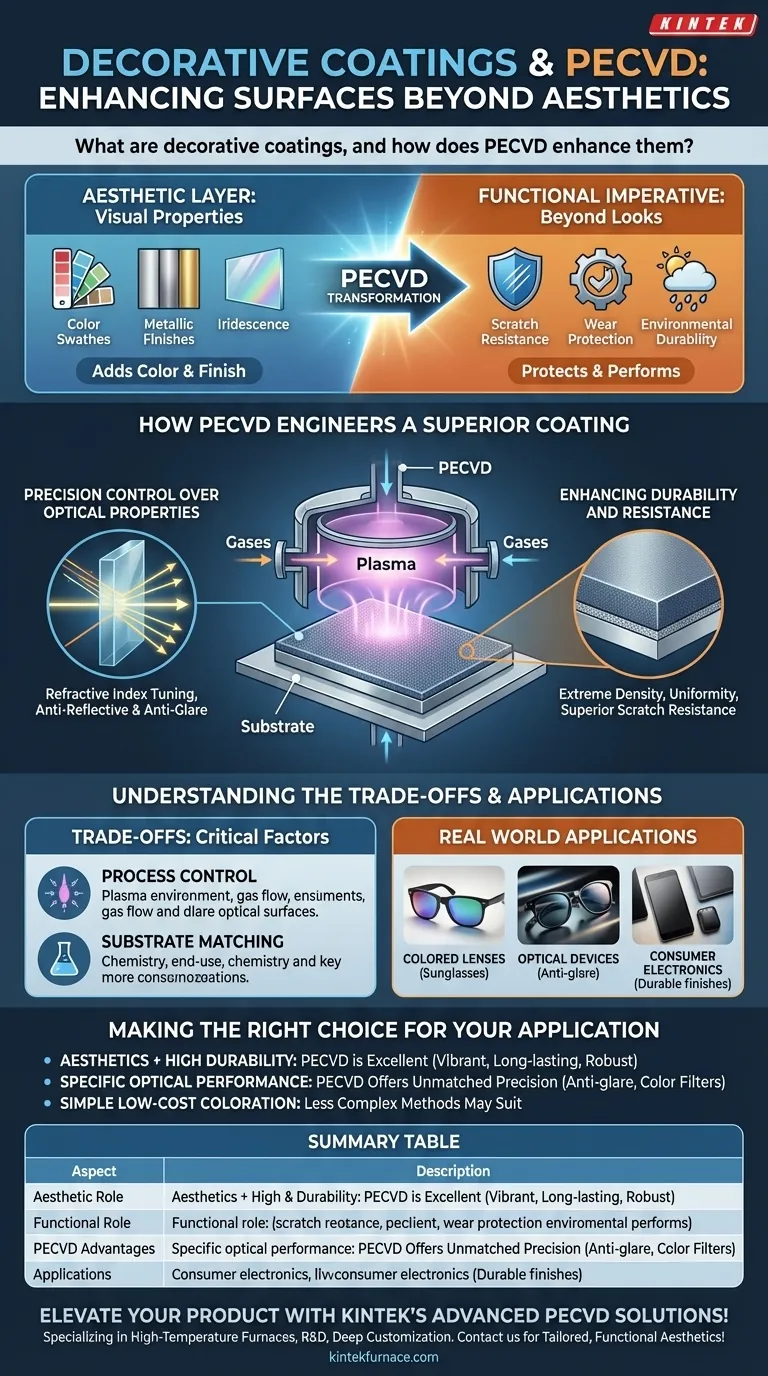

At its core, a decorative coating is a thin film applied to a material, such as glass or plastic, primarily to enhance its aesthetic appeal through color or finish. Plasma-Enhanced Chemical Vapor Deposition (PECVD) elevates these coatings beyond simple decoration by simultaneously embedding advanced functional properties, such as exceptional scratch resistance and precise optical control, directly into the material's surface.

PECVD transforms the concept of a decorative coating from a simple layer of color into a highly engineered surface. It allows for the fusion of aesthetic beauty with measurable performance benefits like durability and specific light-handling properties.

Beyond Color: The Dual Role of Modern Coatings

Modern applications demand more from a surface than just a pleasing look. The expectation is a combination of form and function, which is where advanced deposition technologies become critical.

The Aesthetic Layer

The primary goal of a decorative coating is to alter the visual properties of a substrate. This can include adding a specific color, creating a metallic or iridescent finish, or changing its reflectivity.

The Functional Imperative

Beyond looks, these coatings must often perform a job. They are expected to protect the underlying material from scratches, wear, and environmental factors. This dual requirement is what separates a simple paint from an advanced engineered coating.

How PECVD Engineers a Superior Coating

PECVD is a process that uses plasma to help deposit a thin, solid film from a gaseous state onto a substrate. This method provides a level of control that is difficult to achieve with traditional coating techniques.

Precision Control Over Optical Properties

The key advantage of PECVD is the ability to meticulously manage process parameters like pressure, temperature, and gas composition. This control directly influences the refractive index of the deposited film.

By precisely tuning the refractive index, engineers can create coatings with specific optical behaviors, such as anti-reflective or anti-glare surfaces. This is essential for products like high-performance sunglasses or precision optical instruments.

Enhancing Durability and Resistance

The plasma-enhanced process creates films that are extremely dense, uniform, and well-adhered to the substrate. The result is a hard surface that provides superior scratch resistance and overall durability compared to many conventional decorative methods.

Understanding the Trade-offs

While powerful, PECVD is a sophisticated process that requires careful consideration. Its value is tied directly to the precision with which it is applied.

The Critical Role of Process Control

The quality and properties of the final coating are entirely dependent on maintaining exact control over the plasma environment. Minor deviations in gas flow or pressure can significantly alter the color, uniformity, and performance of the film.

Substrate and Application Matching

PECVD is not a one-size-fits-all solution. The choice of coating chemistry and process parameters must be carefully matched to the substrate material and the product's end-use to ensure proper adhesion and functionality. A coating designed for glass may not perform the same way on a polymer.

Examples in the Real World

This technology is not theoretical; it is used across a wide range of products. Common applications include colored lenses for sunglasses, protective and anti-glare coatings on optical devices, and durable decorative finishes on consumer electronics.

Making the Right Choice for Your Application

Selecting the right coating technology depends entirely on your project's primary goal.

- If your primary focus is aesthetics with high durability: PECVD is an excellent choice for creating vibrant, long-lasting decorative films that also provide robust protection against scratches and wear.

- If your primary focus is specific optical performance: PECVD offers unmatched precision for engineering functional surfaces like anti-glare layers or specific color filters for advanced optical systems.

- If your primary focus is simple, low-cost coloration: A less complex method may be more suitable, as PECVD's value lies in its ability to deliver high-performance, engineered properties.

Ultimately, employing PECVD allows you to treat a product's surface not as an afterthought, but as an integral, high-performing component.

Summary Table:

| Aspect | Description |

|---|---|

| Aesthetic Role | Adds color, metallic finishes, or iridescence to improve visual appeal. |

| Functional Role | Provides scratch resistance, wear protection, and environmental durability. |

| PECVD Advantages | Enables precise optical control (e.g., anti-reflective) and enhanced film density for durability. |

| Applications | Used in sunglasses, optical devices, and consumer electronics for combined beauty and performance. |

Elevate your product's surface with KINTEK's advanced PECVD solutions! We specialize in high-temperature furnaces, including CVD/PECVD systems, backed by exceptional R&D and in-house manufacturing. Our deep customization capabilities ensure we precisely meet your unique experimental needs, delivering durable, high-performance decorative coatings for industries like optics and electronics. Contact us today to discuss how we can enhance your materials with tailored, functional aesthetics!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition