At its core, argon's primary advantages over other inert gases in heat treatment are its higher density and its superior balance of cost and performance. Unlike lighter gases, it forms a more effective protective layer over materials, and it provides true chemical inertness in applications where cheaper alternatives like nitrogen would react with the metal.

The choice of an inert gas is a technical trade-off between cost, density, and chemical reactivity. Argon excels by offering true inertness for sensitive alloys at a lower cost than helium, while its high density provides more reliable protection than nitrogen or helium in many furnace setups.

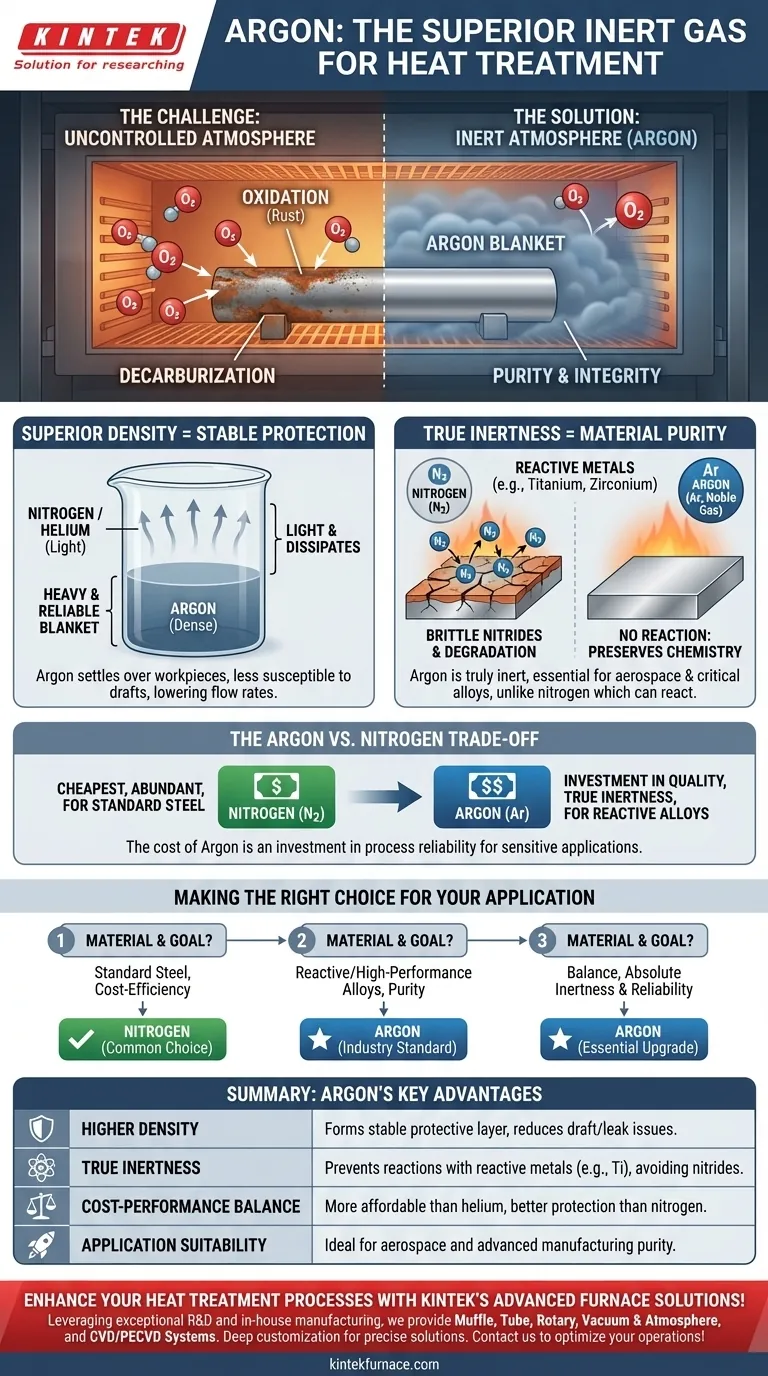

The Role of an Inert Atmosphere

Heat treatment requires precise control. The primary purpose of introducing an inert gas like argon is to create a protective atmosphere inside the furnace.

This controlled environment displaces oxygen and other reactive gases. This prevents unwanted chemical reactions such as oxidation (rusting) and decarburization (loss of carbon content in steel), which can compromise a part's structural integrity.

An inert atmosphere is critical for producing clean, high-purity components, ensuring they meet strict performance and quality standards.

Argon's Key Advantages Explained

Superior Density for Better Protection

Argon is significantly denser than air, nitrogen, and especially helium. This physical property is a distinct operational advantage.

Because it is heavy, argon gas effectively "sinks" and settles over the workpieces, creating a stable, protective blanket. This displacement of ambient air is more reliable and less susceptible to minor drafts or furnace leaks.

Lighter gases like helium dissipate quickly and require higher flow rates or perfectly sealed environments to achieve the same level of protection, increasing operational complexity and cost.

True Inertness for Reactive Metals

While nitrogen is often used as a cost-effective inert gas, it is not truly inert under all conditions. At high heat-treating temperatures, nitrogen can react with certain metals.

Alloys based on titanium, zirconium, and other high-performance metals are prone to absorbing nitrogen, which forms brittle nitrides on the surface and degrades the material's properties.

Argon, as a noble gas, does not react with these metals even at extreme temperatures. This makes it essential for critical applications in industries like aerospace and advanced manufacturing, where material purity is non-negotiable.

Understanding the Trade-offs: Argon vs. Nitrogen

The most common decision in heat treatment is not between argon and helium, but between argon and nitrogen. Understanding their differences is key.

The Cost Calculation

Nitrogen is the cheapest and most abundant option for creating an inert atmosphere. Its low cost makes it the default choice for processing standard steels and other non-reactive metals.

Argon is more expensive than nitrogen. Its use is justified when the risk of nitrogen contamination is unacceptable or when its higher density provides a tangible process benefit.

The higher cost of argon is an investment in material quality and process reliability, preventing costly part failures in sensitive applications.

The Reactivity Factor

For the vast majority of carbon and alloy steels, nitrogen is sufficiently inert and works perfectly well.

For additively manufactured parts, high-performance alloys, and reactive metals, argon is the superior technical choice. It guarantees a truly non-reactive environment, preserving the precise chemistry and performance characteristics of the material.

Making the Right Choice for Your Application

Choosing the correct gas requires aligning your material requirements with your budget.

- If your primary focus is cost-efficiency for non-reactive metals: Nitrogen is almost always the correct choice for heat-treating common steels.

- If your primary focus is purity for reactive or high-performance alloys: Argon is the industry standard for protecting materials like titanium and for critical applications in aerospace.

- If your primary focus is balancing performance and budget: Argon serves as the essential upgrade from nitrogen when absolute inertness and reliable gas coverage are required.

Ultimately, selecting the right inert gas is a critical decision that directly impacts the quality and reliability of your final product.

Summary Table:

| Advantage | Description |

|---|---|

| Higher Density | Forms a stable protective layer, reducing susceptibility to drafts and leaks. |

| True Inertness | Prevents reactions with reactive metals like titanium and zirconium, avoiding nitride formation. |

| Cost-Performance Balance | More affordable than helium while offering better protection and inertness than nitrogen. |

| Application Suitability | Ideal for aerospace and advanced manufacturing where material purity is critical. |

Enhance your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, especially for reactive metals. Contact us today to discuss how we can optimize your operations and ensure superior material quality!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality