In short, rapid heating and cooling features in a muffle furnace directly translate to increased operational efficiency. This capability allows you to complete thermal processing cycles in significantly less time, which fundamentally improves laboratory or production throughput.

While all muffle furnaces provide a controlled, high-temperature environment, the addition of rapid heating and cooling transforms the furnace from a simple oven into a high-performance tool. This feature is not just about speed; it's about gaining greater control over the entire thermal process, enabling new material treatments and maximizing your workflow.

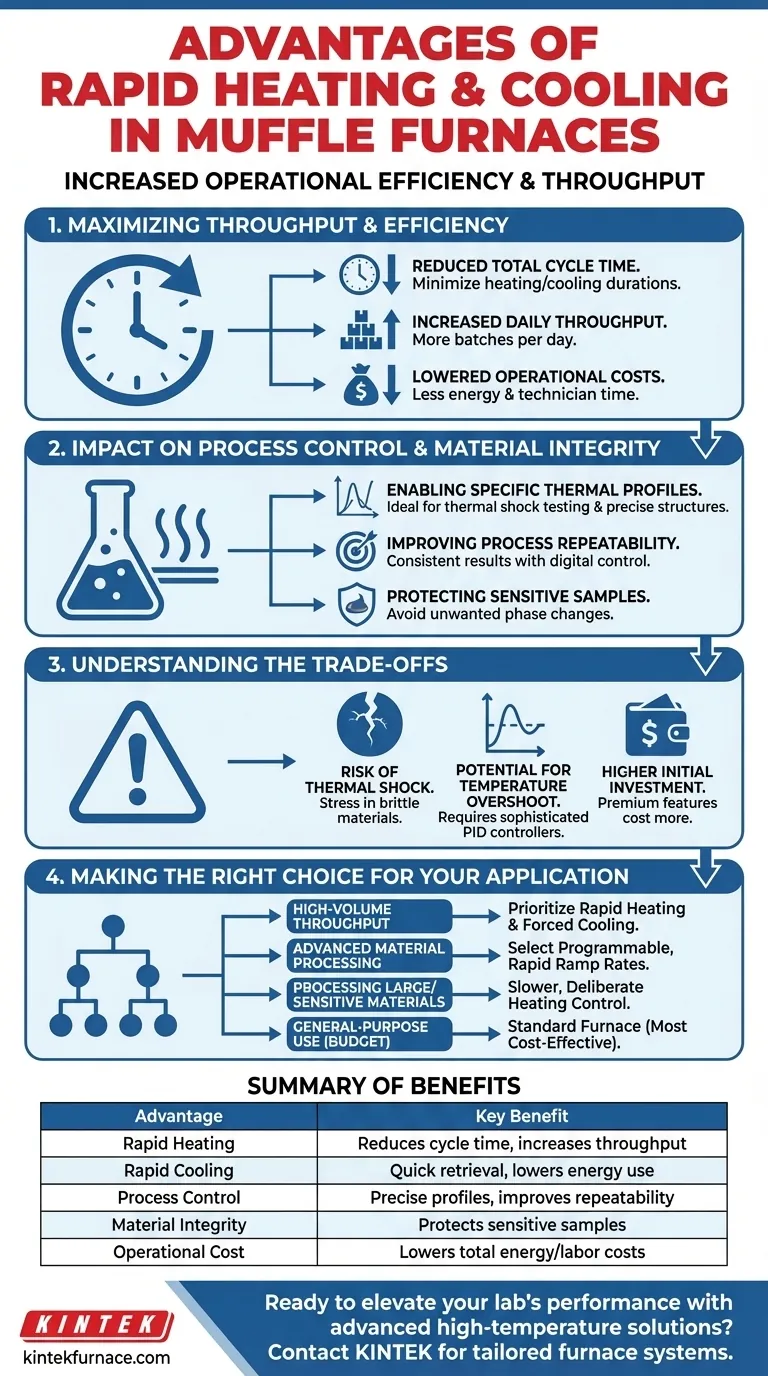

The Core Advantage: Maximizing Throughput and Efficiency

The most significant benefit of rapid temperature cycling is the direct impact on productivity. By minimizing the time the furnace spends heating up and cooling down, you shorten the entire process loop.

Reducing Total Cycle Time

A standard furnace can take over an hour just to reach its target temperature. Models designed for rapid heating can achieve this much faster, dramatically cutting down on non-productive waiting time.

The same principle applies to cooling. Instead of waiting hours for a furnace to cool naturally, forced cooling systems can bring the chamber back to a safe handling temperature quickly, allowing you to retrieve your sample and begin the next cycle.

Increasing Daily Throughput

For quality control labs, research facilities, or small-scale production, this time savings is cumulative. Shorter cycle times mean you can run more batches in a single day, effectively increasing the capacity of your facility without adding more equipment.

Lowering Operational Costs

Efficiency isn't just about time; it's also about cost. While peak power draw might be higher during ramp-up, the significantly shorter overall run time can lead to lower total energy consumption per cycle. Furthermore, less time spent waiting for the furnace translates to more efficient use of technician and operator time.

The Impact on Process Control and Material Integrity

Beyond simple speed, rapid cycling offers a higher degree of control that is critical for advanced material science applications. It gives you the power to dictate a precise thermal profile rather than being limited by the furnace's physical properties.

Enabling Specific Thermal Profiles

Some processes, like thermal shock testing or creating specific crystalline structures, require extremely fast changes in temperature. A conventional furnace is incapable of performing these treatments. Rapid heating and cooling are not just an enhancement but a requirement for such applications.

Improving Process Repeatability

Digitally controlled rapid heating systems execute a programmed thermal profile with high precision. This ensures that every batch is exposed to the exact same conditions, leading to more consistent and repeatable results compared to slower, less-controlled heating cycles.

Protecting Sensitive Samples

For certain materials, spending prolonged periods at intermediate temperatures can cause unwanted phase changes, oxidation, or grain growth. The ability to move through these temperature zones quickly can be crucial for preserving the final integrity and properties of the sample.

Understanding the Trade-offs

While highly beneficial, this feature is not universally superior for every application. Understanding its limitations is key to making an informed decision.

The Risk of Thermal Shock

The very feature that enables thermal shock testing can be a drawback for other materials. Rapid temperature changes can induce stress in brittle materials like ceramics or glass, causing them to crack or shatter. A programmable controller that also allows for slow ramp rates is essential for versatility.

Potential for Temperature Overshoot

Systems designed for rapid heating must be paired with a sophisticated PID controller to prevent the temperature from exceeding the setpoint. A furnace that heats quickly but consistently overshoots its target can ruin samples and compromise results.

Higher Initial Investment

Furnaces equipped with advanced insulation, high-power heating elements, and forced cooling systems typically come at a higher price point. The efficiency gains must be weighed against the increased upfront capital cost.

Making the Right Choice for Your Application

Ultimately, the need for rapid heating and cooling depends entirely on your specific goals and materials.

- If your primary focus is high-volume throughput: Prioritize a model with rapid heating and forced cooling to maximize the number of cycles you can run per day.

- If your primary focus is advanced material processing: Select a furnace that offers programmable, rapid ramp rates to achieve specific and repeatable thermal profiles.

- If your primary focus is processing large or highly sensitive materials: A furnace with slower, more deliberate heating control may be more important than raw speed to prevent thermal shock.

- If your primary focus is general-purpose use on a limited budget: A standard furnace without premium rapid-cycling features will be the most cost-effective solution and will perform reliably for many common applications.

Choosing the right furnace is about aligning the equipment's capabilities with your unique operational and scientific needs.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Rapid Heating | Reduces cycle time, increases daily throughput |

| Rapid Cooling | Enables quick sample retrieval, lowers energy use |

| Process Control | Allows precise thermal profiles, improves repeatability |

| Material Integrity | Protects sensitive samples from unwanted changes |

| Operational Cost | Lowers total energy and labor costs per cycle |

Ready to elevate your lab's performance with advanced high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our rapid heating and cooling features can maximize your efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation