In industrial thermal processing, an indirect-fired rotary kiln offers a decisive advantage by physically separating the material being processed from the heat source. This fundamental design choice provides unparalleled control over the processing atmosphere, prevents product contamination from combustion gases, and ensures consistent, high-quality results for sensitive and high-value materials.

The core value of an indirect-fired rotary kiln is not just how it heats, but how it isolates. By heating the kiln shell externally, it creates a pristine, highly controlled internal environment, making it the definitive choice for processes where purity and precise atmospheric conditions are paramount.

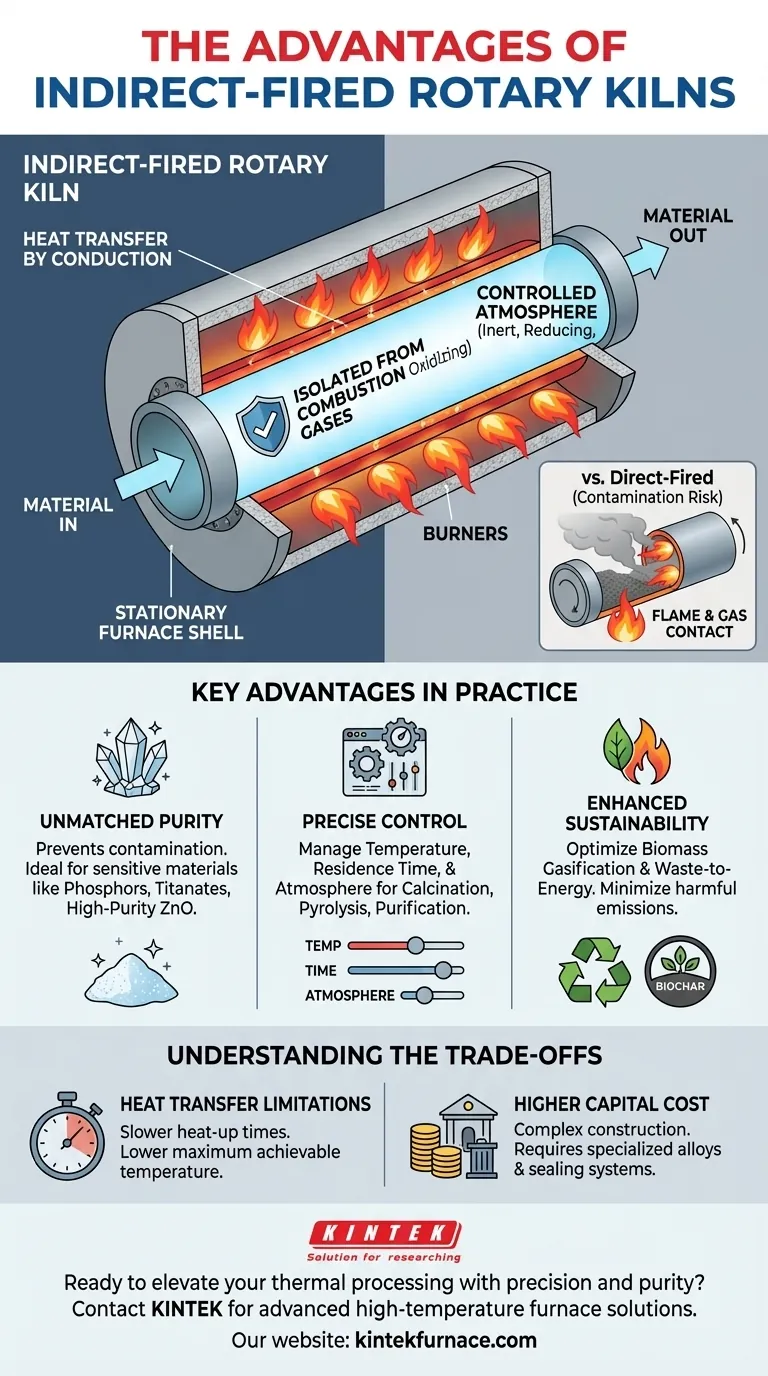

The Core Principle: Isolating the Process from the Heat

The defining characteristic of an indirect-fired kiln is its heating method. Understanding this mechanism is key to appreciating its unique benefits.

How Indirect Heating Works

An indirect-fired rotary kiln is essentially a rotating cylinder enclosed within a larger, stationary furnace or insulated shell.

Burners heat the outside of the rotating cylinder. Heat is then transferred by conduction through the cylinder's shell wall to the material tumbling inside.

This design ensures the material never comes into direct contact with the flame or the flue gases produced by combustion.

The Result: Absolute Atmosphere Control

Because the internal process environment is sealed off from the external furnace, you have total control over its composition.

This allows for the creation of specific atmospheres—such as inert (nitrogen, argon), reducing, or oxidizing—that are essential for targeted chemical reactions, without any interference from combustion byproducts like CO2 and H2O.

Key Advantages in Practice

This separation of heat and process translates directly into tangible operational benefits across numerous industries, from minerals processing to energy production.

Unmatched Purity for Sensitive Materials

The prevention of contamination is the most critical advantage. High-value products that are sensitive to chemical changes or impurities demand this level of isolation.

This makes indirect kilns essential for producing materials like phosphors, titanates, and high-purity zinc oxide, where even trace contamination from flue gas would render the product useless.

Precise Control Over Key Variables

Successful thermal processing depends on managing three factors: temperature, residence time, and atmosphere.

Indirect kilns excel at all three. External heating allows for uniform temperature profiles, the kiln's rotation and angle control material residence time, and the sealed design guarantees atmospheric integrity. This precision is vital for processes like calcination, pyrolysis, and purification.

Enhanced Sustainability and Efficiency

This technology is crucial for modern sustainable processes, such as biomass gasification and waste-to-energy conversion.

By controlling the atmosphere precisely during pyrolysis, operators can optimize the yield and quality of biochar or syngas while minimizing harmful emissions. The enclosed system captures all process outputs for treatment or use.

Understanding the Trade-offs

While powerful, the indirect-fired design is not a universal solution. Acknowledging its limitations is crucial for proper application.

Heat Transfer Limitations

Heating a material through a thick metal shell is inherently less direct than hitting it with a flame. This can lead to slower heat-up times and potential limitations on the maximum achievable material temperature compared to direct-fired designs.

The kiln shell itself becomes the bottleneck, as its material properties dictate the maximum service temperature and the rate of heat transfer.

Higher Initial Capital Cost

The "kiln-within-a-furnace" design is more complex to construct than a simple direct-fired kiln. The need for a large external furnace, specialized alloys for the rotating shell, and sophisticated sealing systems typically results in a higher initial investment.

When a Direct-Fired Kiln Is Better

For processing robust, high-volume, low-cost bulk materials where direct contact with flue gas is acceptable or even beneficial (e.g., drying), a direct-fired kiln is often more economical. Applications like cement clinker production or aggregate drying do not require the purity offered by an indirect design.

Making the Right Choice for Your Application

Selecting the correct kiln technology hinges on a clear understanding of your process requirements and primary business goal.

- If your primary focus is material purity and process control: The absolute isolation of an indirect-fired kiln is non-negotiable for producing high-value chemicals, minerals, or specialty materials.

- If your primary focus is advanced thermal conversion: The precise atmospheric control of an indirect kiln is essential for optimizing pyrolysis, gasification, or waste-to-energy processes.

- If your primary focus is high-volume processing of bulk solids: You should evaluate whether a simpler, more thermally efficient direct-fired kiln can meet your needs at a lower capital cost.

Ultimately, the indirect-fired rotary kiln is a specialized tool engineered for precision, enabling transformations that would be impossible in any other system.

Summary Table:

| Advantage | Description |

|---|---|

| Material Purity | Prevents contamination from combustion gases, ideal for sensitive materials like phosphors and titanates. |

| Atmosphere Control | Enables creation of inert, reducing, or oxidizing atmospheres for precise chemical reactions. |

| Process Precision | Offers uniform temperature, controlled residence time, and consistent results for calcination and pyrolysis. |

| Sustainability | Supports biomass gasification and waste-to-energy with optimized yields and reduced emissions. |

Ready to elevate your thermal processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're handling sensitive materials or optimizing pyrolysis processes, we can help you achieve superior results. Contact us today to discuss how our solutions can benefit your laboratory!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating