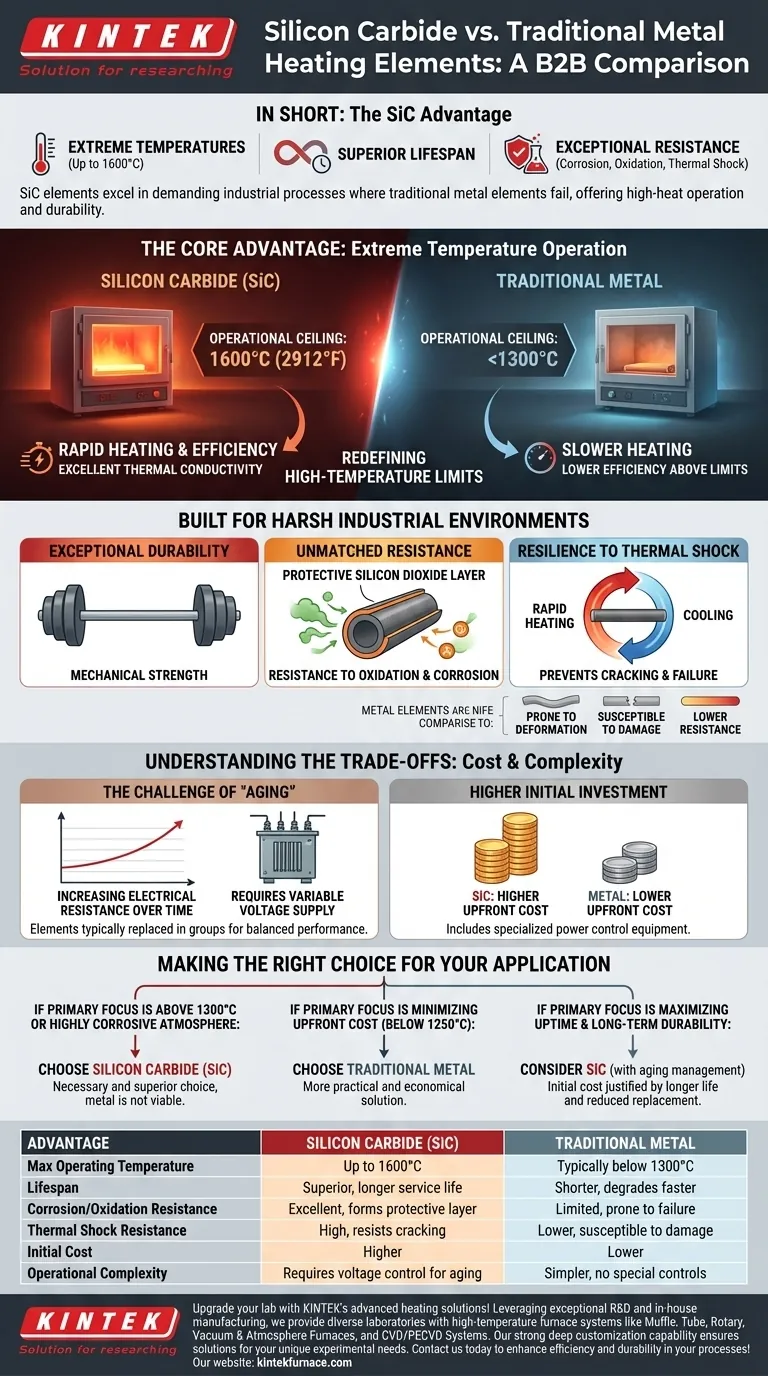

In short, the primary advantages of silicon carbide (SiC) heating elements are their ability to operate at extremely high temperatures, their superior lifespan, and their exceptional resistance to chemical corrosion, oxidation, and thermal shock. These attributes make them uniquely suited for demanding industrial processes where traditional metal elements would quickly fail.

While metal heating elements are sufficient for many applications, silicon carbide represents a significant step-up in material science. It allows for operations in extreme heat and harsh chemical environments, but this superior performance requires a clear understanding of its unique lifecycle costs and operational demands.

The Core Advantage: Extreme Temperature Operation

The fundamental difference between SiC and metal elements is their operational ceiling. SiC was engineered specifically to overcome the limitations of metal alloys in high-heat environments.

Redefining High-Temperature Limits

Silicon carbide elements can operate at furnace temperatures up to 1600°C (2912°F). This is significantly higher than the maximum temperatures for even the best metallic heating elements, which typically fail or degrade rapidly above 1300°C.

Rapid Heating and Efficiency

SiC exhibits excellent thermal conductivity, allowing it to reach its target temperature very quickly. This rapid heating capability can reduce process cycle times and lower overall energy consumption, contributing to greater operational efficiency and industrial sustainability.

Built for Harsh Industrial Environments

Beyond just heat, industrial furnaces often involve corrosive atmospheres and rapid temperature changes. SiC elements are structurally and chemically more robust than their metallic counterparts in these conditions.

Exceptional Durability and Mechanical Strength

SiC elements possess outstanding mechanical strength, even at extreme temperatures. This makes them far less prone to breakage or deformation, reducing the need for frequent replacements and the associated maintenance downtime.

Unmatched Resistance to Oxidation and Corrosion

During operation, a silicon carbide element forms a protective surface layer of silicon dioxide. This film provides superior resistance to oxidation and chemical corrosion, extending the element's service life in aggressive furnace atmospheres.

Resilience to Thermal Shock

Industrial processes often involve rapid heating and cooling cycles. SiC's material properties give it excellent resistance to thermal shock, preventing the cracking and failure that can occur with less resilient materials under such stress.

Understanding the Trade-offs: Cost and Complexity

The superior performance of SiC elements comes with specific considerations that are critical for making an informed decision. They are not a universal replacement for metal elements.

The Challenge of "Aging"

The most significant operational characteristic of SiC is aging. Over its service life, an SiC element's electrical resistance gradually increases. This requires a power supply with a variable voltage output (often a multi-tap transformer) to maintain consistent power delivery.

This aging process also means elements are typically replaced in groups to maintain balanced performance, unlike metal elements which can often be replaced individually.

Higher Initial Investment

Silicon carbide elements are more expensive than traditional metallic elements on a per-unit basis. Furthermore, the need for specialized power control equipment adds to the initial capital expenditure.

Making the Right Choice for Your Application

Selecting the correct heating element technology is a trade-off between performance requirements, operational complexity, and budget.

- If your primary focus is operating above 1300°C or in a highly corrosive atmosphere: Silicon carbide is the necessary and superior choice, as metallic elements are not viable.

- If your primary focus is minimizing upfront cost for a lower-temperature process (below 1250°C): Traditional metal elements remain the more practical and economical solution.

- If your primary focus is maximizing uptime and long-term durability: The initial cost of SiC may be justified by its longer life and reduced replacement frequency, provided you have the systems to manage its aging.

Ultimately, choosing SiC is an investment in high-performance capability for applications where standard materials are simply not an option.

Summary Table:

| Advantage | Silicon Carbide (SiC) | Traditional Metal |

|---|---|---|

| Max Operating Temperature | Up to 1600°C | Typically below 1300°C |

| Lifespan | Superior, longer service life | Shorter, degrades faster |

| Corrosion/Oxidation Resistance | Excellent, forms protective layer | Limited, prone to failure |

| Thermal Shock Resistance | High, resists cracking | Lower, susceptible to damage |

| Initial Cost | Higher | Lower |

| Operational Complexity | Requires voltage control for aging | Simpler, no special controls |

Upgrade your lab with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance efficiency and durability in your processes!

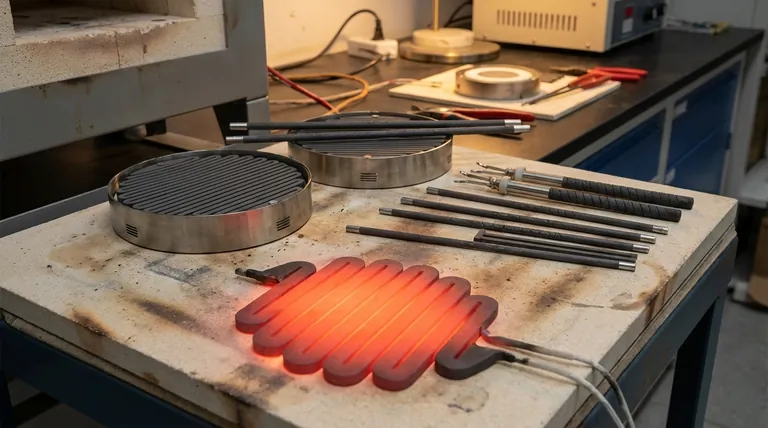

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality