At their core, advanced porcelain furnaces move beyond simple heating to offer precise, repeatable control over the entire firing environment. Key advancements include highly programmable firing cycles, sophisticated thermal management systems for uniform heating and controlled cooling, and intelligent user interfaces that streamline the workflow for the technician. These features work in concert to ensure the highest quality ceramic restorations.

The evolution of porcelain furnaces is not just about reaching higher temperatures; it's about achieving unprecedented control. Advanced features give the dental technician the power to precisely manipulate heat, time, and atmosphere, transforming the firing process from an approximation into a science.

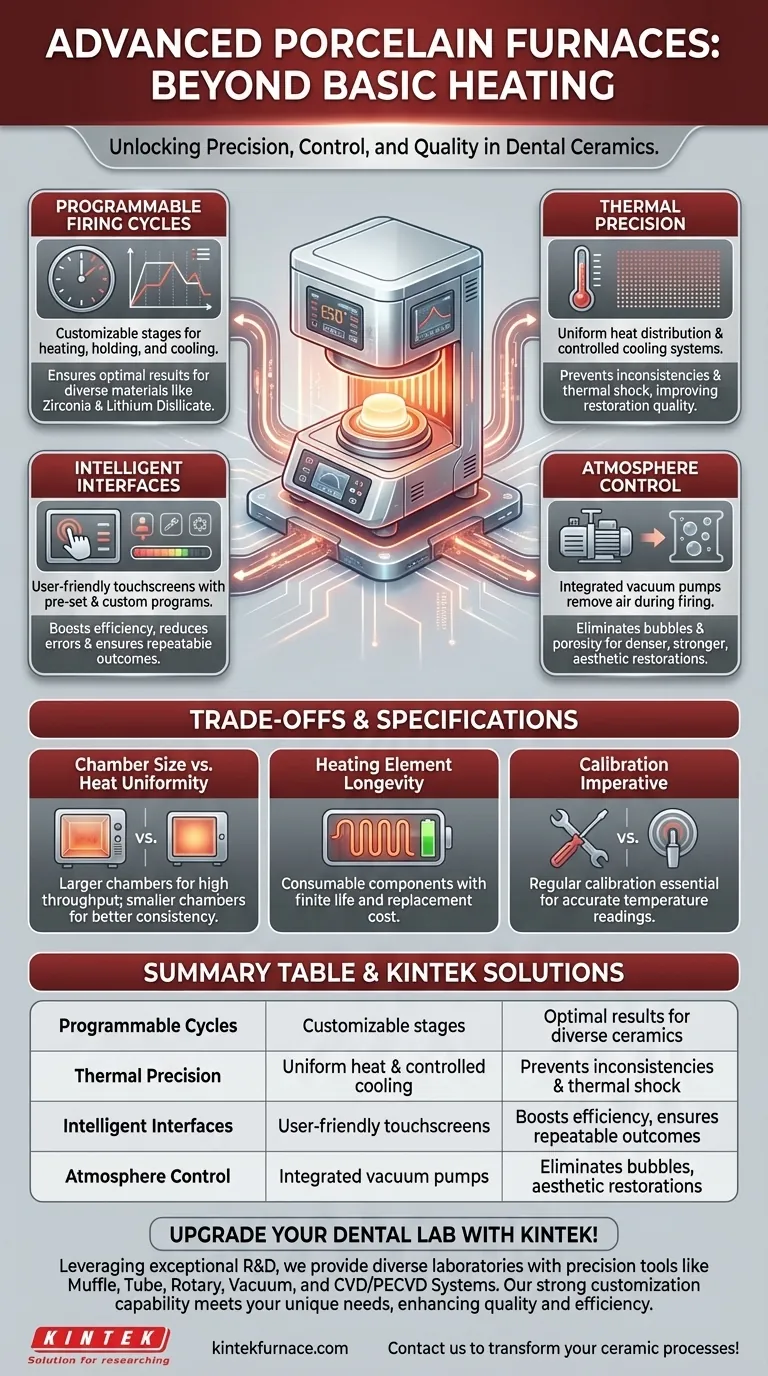

Beyond Basic Heating: The Pillars of Advanced Control

A modern furnace is a sophisticated instrument designed to manage the complex material science of dental ceramics. The most significant advancements focus on giving the operator granular control over every critical variable.

Granular Control with Programmable Firing Cycles

The ability to program a firing cycle is the foundation of an advanced furnace. This allows a technician to customize every stage of the process—from the initial drying and heating rate to the final hold time and temperature.

This level of control is essential for working with the diverse range of modern ceramics. A program for a high-translucency zirconia crown will differ significantly from one for a lithium disilicate veneer, and programmability ensures optimal results for each.

The Pursuit of Thermal Precision

Simply reaching a target temperature is not enough. Advanced furnaces focus on the quality and uniformity of that heat.

Uniform heat distribution is critical. Multiple or strategically placed heating elements, often made of materials like molybdenum disilicide, ensure the entire restoration heats evenly. This prevents hot spots that can cause inconsistencies in shade or fit.

Equally important is a controlled cooling system. Rapid, uncontrolled cooling can introduce thermal shock, leading to micro-cracks and restoration failure. Advanced furnaces manage the cooling rate to ensure the ceramic structure settles predictably and without stress.

Intelligent Interfaces and Workflow Integration

Modern furnaces feature user-friendly interfaces, often with full-color touchscreens. These systems simplify the programming process and reduce the chance of user error.

Technicians can monitor the firing cycle in real-time, access dozens of pre-set manufacturer programs, and easily save their own custom cycles. This boosts efficiency and guarantees consistent, repeatable results from one case to the next.

Atmosphere Control: The Role of Vacuum Systems

Many high-end furnaces incorporate an integrated vacuum pump. During the heating cycle, the pump removes air from the firing chamber before the porcelain reaches its vitrification (glazing) temperature.

This process eliminates oxygen that can get trapped within the porcelain, preventing bubbles and porosity. The result is a denser, stronger, and more translucent restoration with superior aesthetics.

Understanding the Trade-offs and Key Specifications

While advanced features offer significant benefits, it's crucial to understand their practical implications and the technical specifications that define them.

Chamber Size vs. Heat Uniformity

A larger firing chamber allows for higher throughput or the firing of larger cases, like full-arch bridges. However, maintaining perfect heat uniformity becomes more challenging as chamber size increases.

For most crown and bridge work, a standard chamber (e.g., ~85mm diameter) is more than sufficient and often provides more consistent thermal performance.

Heating Element Longevity and Cost

High-performance heating elements are consumables. They have a finite operational life and represent an ongoing maintenance cost. Understanding the expected lifespan and replacement cost of these elements is a key part of evaluating the total cost of ownership for any furnace.

The Calibration Imperative

An advanced furnace's precision is only as good as its calibration. Temperature sensors can drift over time, leading to inaccurate firing. Regular calibration is not an optional step; it is essential maintenance required to ensure the furnace continues to deliver accurate and predictable results.

Making the Right Choice for Your Lab

Selecting a furnace requires matching its capabilities to the primary goals of your dental laboratory.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with exceptional thermal precision and an integrated, high-performance vacuum system.

- If your primary focus is high-volume production: Look for robust reliability, a user-friendly interface with extensive pre-set programs, and proven workflow efficiency.

- If your primary focus is working with diverse materials: Ensure the furnace offers maximum programmability, a wide temperature range, and flexible control over heating and cooling rates.

Investing in the right furnace is an investment in the predictability, quality, and consistency of your final restorations.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Programmable Firing Cycles | Customizable stages for heating, holding, and cooling | Ensures optimal results for diverse ceramics like zirconia and lithium disilicate |

| Thermal Precision | Uniform heat distribution and controlled cooling systems | Prevents inconsistencies and thermal shock, improving restoration quality |

| Intelligent Interfaces | User-friendly touchscreens with pre-set and custom programs | Boosts efficiency, reduces errors, and ensures repeatable outcomes |

| Atmosphere Control | Integrated vacuum pumps to remove air during firing | Eliminates bubbles and porosity for denser, stronger, and more aesthetic restorations |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, enhancing restoration quality and workflow efficiency. Contact us today to discuss how our tailored solutions can transform your ceramic processes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency