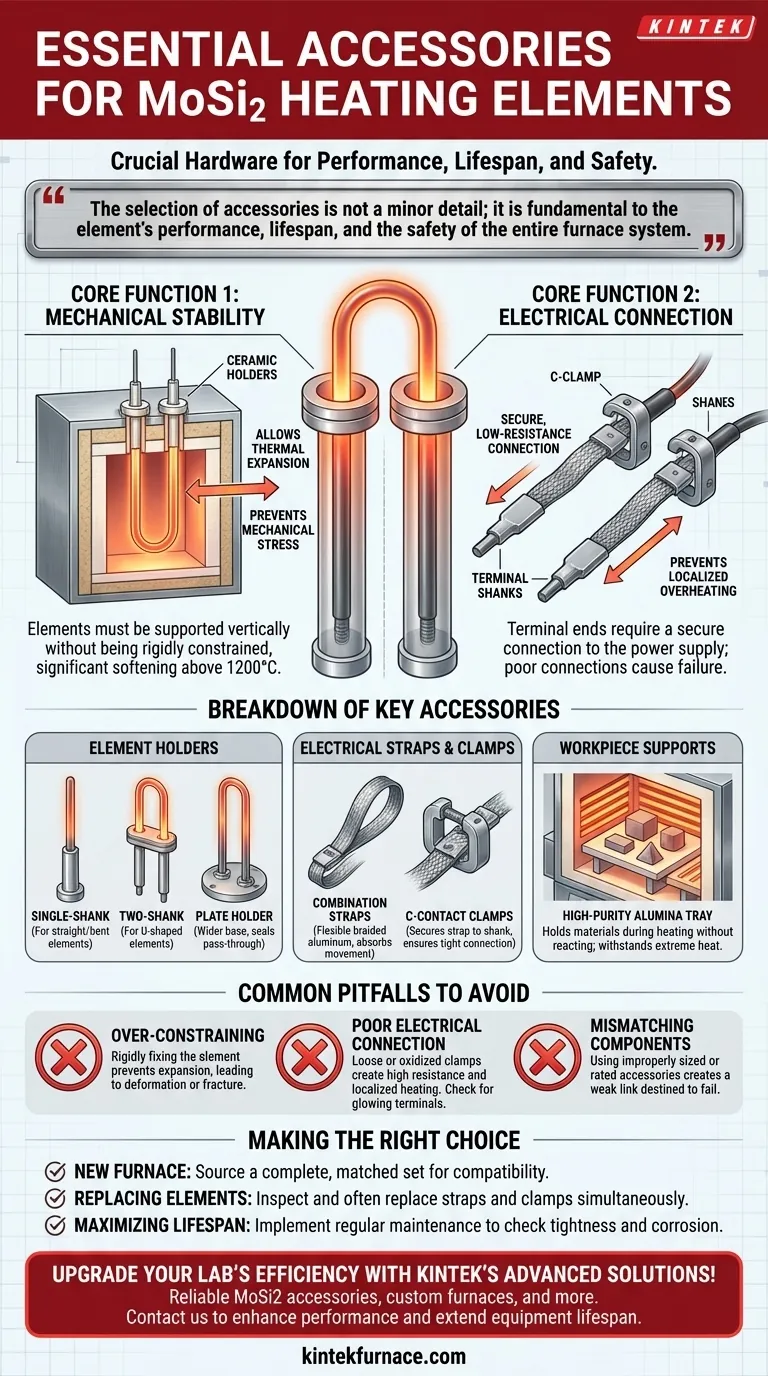

The essential accessories for MoSi2 heating elements are the specialized pieces of hardware used to securely mount the elements and provide a reliable electrical connection. These include various holders, straps, and clamps designed to handle extreme temperatures and prevent premature element failure.

The selection of accessories for a MoSi2 heating element is not a minor detail; it is fundamental to the element's performance, lifespan, and the safety of the entire furnace system. The right hardware prevents mechanical stress and ensures a reliable electrical connection—the two most critical factors for longevity.

The Core Function of MoSi2 Accessories

MoSi2 elements operate under extreme conditions, becoming soft and pliable at high temperatures. Their accessories perform two distinct but equally critical jobs: providing stable mechanical support and guaranteeing a flawless electrical connection.

Ensuring Mechanical Stability

MoSi2 elements are brittle at room temperature but soften significantly above 1200°C. They must be supported vertically without being rigidly constrained.

Holders are designed to allow the element to hang freely, accommodating thermal expansion and contraction during heat cycles. Preventing mechanical stress is paramount to avoiding element fracture.

Guaranteeing Electrical Connection

The terminal ends (or "shanks") of MoSi2 elements operate at a much lower temperature than the hot zone. They require a secure, low-resistance connection to the power supply.

A poor connection creates high electrical resistance, generating localized heat at the terminal. This can quickly destroy the terminal shank and lead to element failure, even while the main heating section remains intact.

A Breakdown of Key Accessories

Each accessory serves a specific purpose in the complete system. Using the correct combination is essential for a successful installation.

Element Holders (Plate, Single & Two-Shank)

These components pass through the furnace's refractory insulation and hold the element in its correct vertical position.

- Single-Shank Holders: Used for straight or bent elements with a single terminal passing through the furnace roof or wall.

- Two-Shank Holders: Designed to support U-shaped elements, securing both cold-end shanks.

- Plate Holders: Provide a wider base of support and are often used to seal the pass-through opening more effectively.

Electrical Straps & Clamps

These components bridge the gap between the element's terminals and the power cabling.

- Combination Straps: Typically made of flexible, braided aluminum, these straps connect the element shank to the power source. Their flexibility is crucial for absorbing movement from thermal expansion without stressing the element.

- C-Contact Clamps: These secure the strap firmly to the cylindrical element shank, ensuring a tight, low-resistance connection capable of handling high amperage.

Workpiece Supports (High-Purity Alumina Trays)

These are not accessories for the element itself, but for the material being heated by the element.

In applications like ceramic firing or sintering, the product must rest on a surface that can also withstand extreme heat. High-purity alumina trays are common because they remain stable and do not chemically react with the workpiece or the furnace atmosphere at temperature.

Common Pitfalls to Avoid

Mistakes in accessory selection or installation are a primary cause of premature element failure. Understanding these risks is key to reliable furnace operation.

The Danger of Over-Constraining

Never rigidly fix a MoSi2 element. The holders must allow it to hang freely and expand. Any binding or twisting force applied to the element, especially when hot, will lead to deformation or fracture.

The Risk of a Poor Electrical Connection

A loose or oxidized clamp is the most common failure point. Periodically check that all clamps are tight and that straps are free of corrosion. A glowing or discolored terminal is a clear sign of a high-resistance connection that requires immediate attention.

Mismatching Components

Always use accessories specifically designed for your model of MoSi2 element. Using an improperly sized clamp or a strap with insufficient amperage rating will create a weak link in the system that is destined to fail.

Making the Right Choice for Your Application

Your goal determines how you should approach accessory selection and maintenance.

- If your primary focus is building a new furnace: Source a complete, matched set of elements, holders, and straps from a reputable manufacturer to guarantee compatibility and proper fit.

- If your primary focus is replacing failed elements: Always inspect the existing straps and clamps for signs of heat damage, corrosion, or fatigue. It is often wise to replace the straps and clamps at the same time as the element.

- If your primary focus is maximizing element lifespan: Implement a regular maintenance schedule to check the tightness of all electrical clamps and inspect straps for any signs of oxidation or wear.

By treating accessories as an integral part of the heating system, you ensure operational reliability and protect your investment.

Summary Table:

| Accessory Type | Key Function | Common Examples |

|---|---|---|

| Element Holders | Provide mechanical support and allow for thermal expansion | Single-Shank, Two-Shank, Plate Holders |

| Electrical Straps & Clamps | Ensure secure, low-resistance electrical connections | Combination Straps, C-Contact Clamps |

| Workpiece Supports | Hold materials during heating without reacting | High-Purity Alumina Trays |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating element accessories and more, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance performance and extend the lifespan of your equipment!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability