In choosing between SiC and MoSi2 heating elements, your decision hinges primarily on the maximum operating temperature of your sintering furnace. Silicon Carbide (SiC) is the standard for processes up to approximately 1600°C, while Molybdenum Disilicide (MoSi2) is necessary for higher temperatures, often reaching up to 1800°C. This choice dictates not just performance but also your furnace's maintenance protocol and operational flexibility.

The decision is a strategic trade-off. MoSi2 offers unparalleled high-temperature capability within specific atmospheres, whereas SiC provides greater operational versatility and robustness, especially at temperatures below the 1600°C threshold.

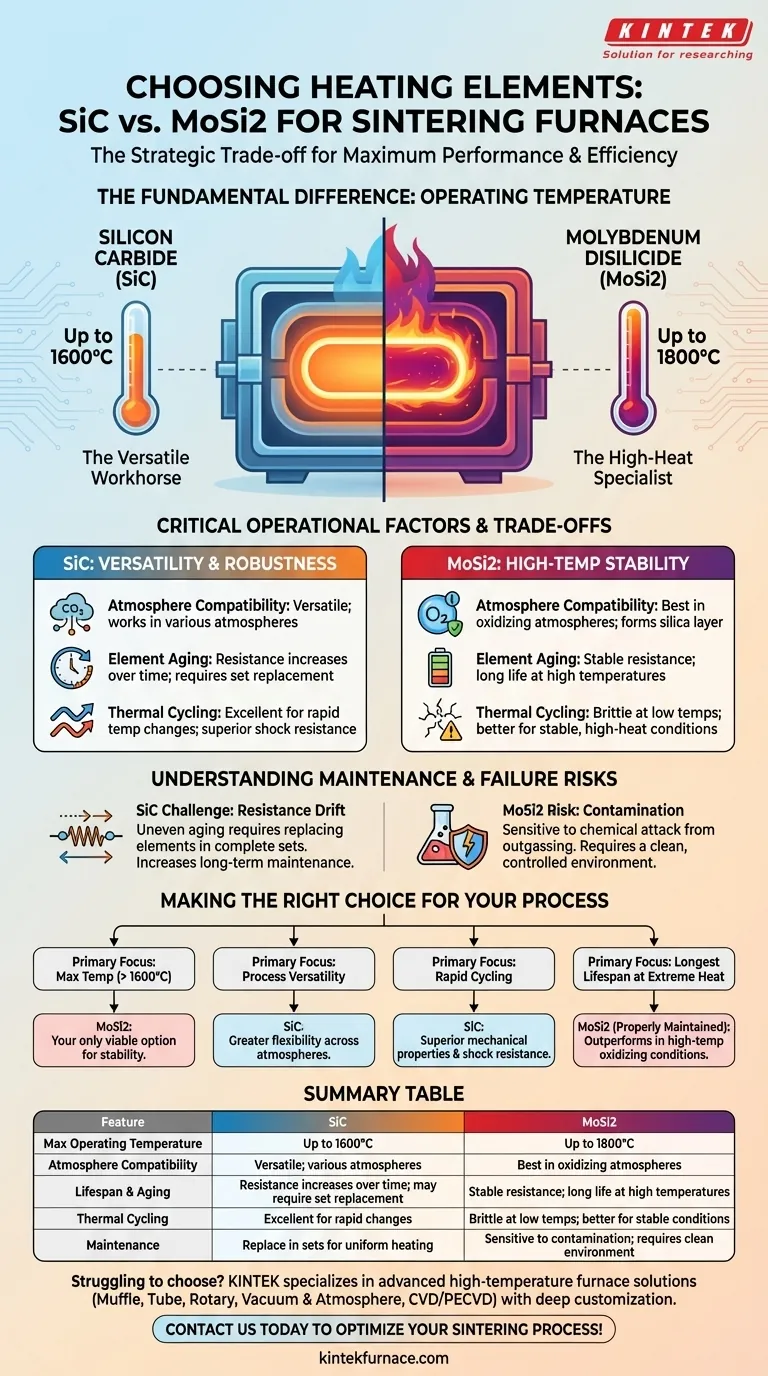

The Fundamental Difference: Operating Temperature

The most critical factor separating these two materials is their effective temperature range. This single parameter will immediately narrow your choice.

Silicon Carbide (SiC): The Versatile Workhorse

SiC elements are the default choice for a wide array of sintering applications with a maximum furnace temperature up to about 1600°C.

They are valued for their high mechanical strength and excellent thermal conductivity, which allows for relatively rapid and efficient heat-up cycles.

Molybdenum Disilicide (MoSi2): The High-Heat Specialist

MoSi2 elements are required when your process demands temperatures that exceed the limits of SiC, typically from 1600°C up to 1800°C.

Their remarkable high-temperature stability comes from the formation of a protective, self-healing layer of silica (SiO₂) on their surface when operated in oxidizing environments.

Beyond Temperature: Critical Operational Factors

Once temperature requirements are met, you must consider the specific conditions of your process, as they directly impact element lifespan and performance.

Furnace Atmosphere

MoSi2 elements excel in oxidizing atmospheres, where their protective silica layer forms and provides outstanding durability. They are not a universal solution for all environments.

SiC is more versatile and can be used in a broader range of atmospheres. This makes it a more flexible option if your process needs or materials change over time.

Element Aging and Lifespan

A defining characteristic of SiC elements is that their electrical resistance increases over time with use. This "aging" process means they deliver less power at the same voltage and require control system adjustments.

MoSi2 elements exhibit stable resistance throughout their life and can have a very long service life, especially when operated consistently at high temperatures (above 1500°C).

Thermal Cycling and Heat-Up Rates

With its superior thermal shock resistance, SiC is better suited for applications involving frequent and rapid temperature changes.

While efficient, MoSi2 can be more brittle at lower temperatures and is more susceptible to mechanical stress during aggressive thermal cycling. It performs best in stable, high-heat conditions.

Understanding the Trade-offs: Maintenance and Failure

The long-term reliability of your furnace is tied to how each element type fails and what is required to maintain it.

The SiC Challenge: Resistance Drift

Because SiC elements age at different rates, a single failed element can unbalance the power distribution in the entire heating system.

To ensure uniform heating, best practice often requires replacing elements in complete sets or matched groups, which can increase long-term maintenance costs.

The MoSi2 Risk: Contamination

MoSi2 elements are more sensitive to chemical contamination from materials outgassing inside the furnace.

Improper furnace cleanliness or processing of certain materials can lead to a chemical attack on the element, compromising its protective layer and causing premature failure. They demand a clean, controlled process environment.

Making the Right Choice for Your Process

Select your heating element by aligning its core strengths with your most critical process requirement.

- If your primary focus is maximum temperature (> 1600°C): MoSi2 is your only viable option and delivers excellent stability in this range.

- If your primary focus is process versatility across different atmospheres: SiC provides greater operational flexibility and is less dependent on a specific oxidizing environment.

- If your primary focus is rapid cycling and thermal shock resistance: SiC's superior mechanical properties and thermal conductivity make it the more robust choice.

- If your primary focus is achieving the longest possible element lifespan at extreme heat: A properly maintained MoSi2 system will outperform SiC in high-temperature, oxidizing conditions.

By understanding these fundamental trade-offs, you can select the element that ensures the long-term reliability and efficiency of your sintering operation.

Summary Table:

| Feature | SiC Heating Element | MoSi2 Heating Element |

|---|---|---|

| Max Operating Temperature | Up to 1600°C | Up to 1800°C |

| Atmosphere Compatibility | Versatile; works in various atmospheres | Best in oxidizing atmospheres |

| Lifespan and Aging | Resistance increases over time; may require set replacement | Stable resistance; long life at high temperatures |

| Thermal Cycling | Excellent for rapid temperature changes | Brittle at low temps; better for stable conditions |

| Maintenance Considerations | Replace in sets for uniform heating | Sensitive to contamination; requires clean environment |

Struggling to choose the right heating element for your sintering furnace? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Our diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements for enhanced efficiency and reliability. Don't let element selection slow you down—contact us today to discuss how we can optimize your sintering process and deliver lasting value!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability