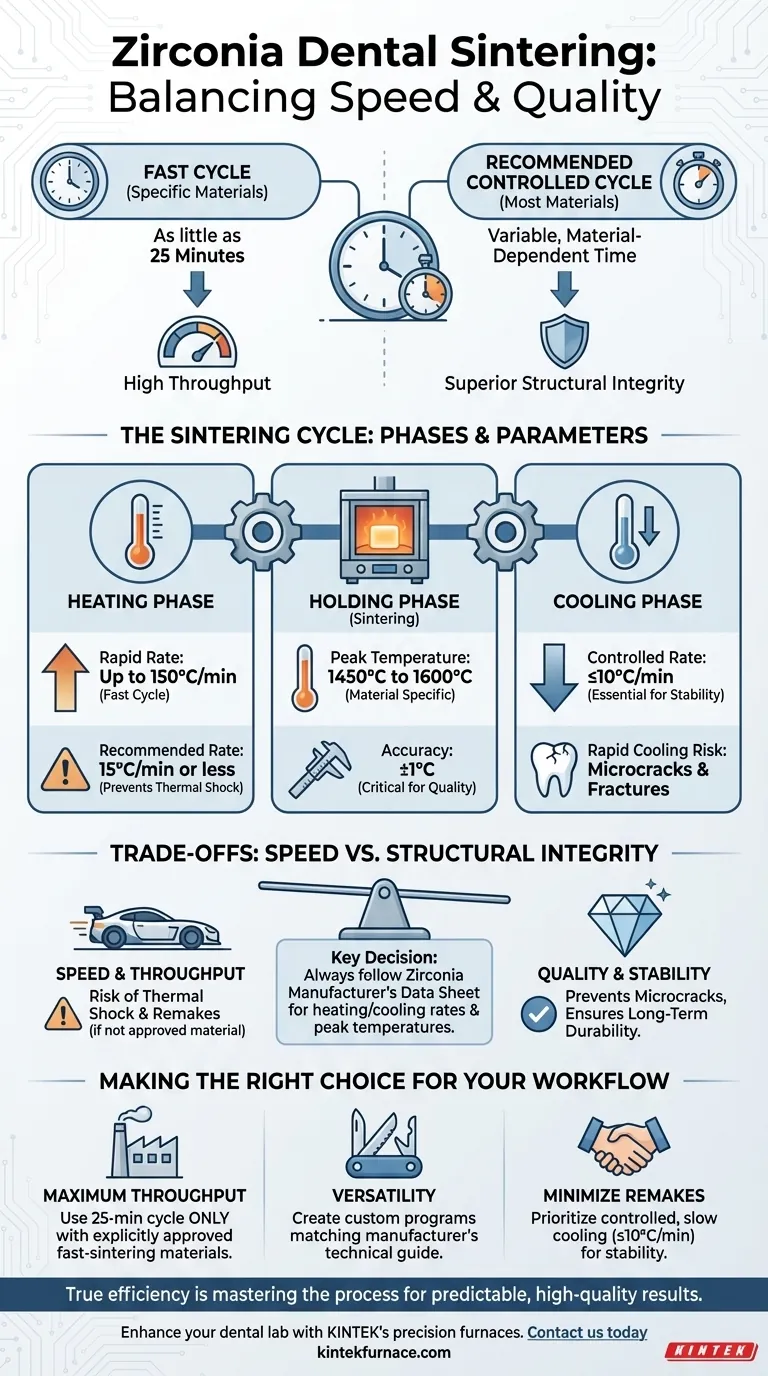

While some cycles are remarkably fast, the time required to complete the sintering process in a Zirconia Dental Sintering Furnace is not a single number. For specifically compatible materials, a full cycle can be completed in as little as 25 minutes. However, the optimal duration is dictated by the specific type of zirconia being used and the desired structural integrity of the final restoration.

The furnace's true value is not just its potential 25-minute speed, but its ability to be precisely controlled. Achieving high-quality, crack-free results depends on matching the heating and cooling rates to the specific zirconia manufacturer's recommendations.

The Anatomy of a Sintering Cycle

Understanding the total time requires looking at the distinct phases of the process. The furnace's programmability allows you to control each one independently.

The Heating Phase

The furnace is capable of an extremely rapid heating rate, reaching up to 150°C per minute. This capability is what enables the advertised 25-minute cycle.

However, for many types of zirconia, a much slower heating rate is essential to prevent thermal shock and potential cracking. A recommended rate is often at or below 15°C per minute.

The Holding Phase (Sintering)

Once the peak temperature is reached, it is held for a specific duration to allow full sintering to occur.

This peak temperature is not universal. It must be adjusted based on the zirconia brand and type, typically falling within a range of 1450°C to 1600°C. The furnace's ±1°C temperature accuracy is critical for ensuring this phase is executed perfectly.

The Cooling Phase

Cooling is just as critical as heating. An uncontrolled or overly rapid cool-down can introduce stress and microcracks into the restoration, compromising its long-term stability.

For this reason, a slow, controlled cooling rate of 10°C per minute or less is often recommended to ensure the highest quality outcome.

Understanding the Trade-offs: Speed vs. Structural Integrity

The core decision for any operator is balancing the need for rapid turnaround with the uncompromising demand for material quality. The furnace's features create a clear choice.

The Risk of Thermal Shock

Heating or cooling zirconia too quickly can cause thermal shock, where different parts of the material expand or contract at different rates. This can lead to fractures, microcracks, and costly remakes.

The 25-minute cycle leverages the furnace's maximum heating rate, but this should only be used with materials specifically formulated to withstand such rapid temperature changes.

When to Use a "Fast" 25-Minute Cycle

The ultra-fast cycle is a powerful tool when used correctly. It is designed for specific zirconia materials engineered for rapid sintering.

Always verify that the zirconia you are using is explicitly approved by its manufacturer for a fast-sintering protocol before using such a program.

The Importance of Material Specifications

The furnace's built-in programs and customizable curves are tools to execute a plan. That plan must come from the zirconia manufacturer's data sheet.

These specifications provide the scientifically validated heating rates, peak temperatures, and cooling rates required to achieve the material's advertised strength and aesthetics without failure.

Making the Right Choice for Your Workflow

Your operational goals should dictate how you use the furnace's capabilities. With its intuitive touch screen and 20 preset programs, you can easily implement the ideal cycle for any situation.

- If your primary focus is maximum throughput with compatible materials: Use the 25-minute fast-sintering cycle, but only with zirconia blocks explicitly designated for this purpose by the manufacturer.

- If your primary focus is versatility across all zirconia brands: Rely on creating custom programs that precisely match the heating, holding, and cooling parameters specified in each material's technical guide.

- If your primary focus is minimizing remakes and ensuring long-term stability: Prioritize a controlled, slow cooling phase (≤10°C/minute), as this is the most critical step for preventing the microcracks that compromise a restoration.

True efficiency in the dental lab comes from mastering the process to achieve predictable, high-quality results every time.

Summary Table:

| Phase | Key Parameter | Typical Duration/Rate | Notes |

|---|---|---|---|

| Heating | Rate | Up to 150°C/min (fast), 15°C/min (recommended) | Fast rate for specific materials; slower prevents thermal shock. |

| Holding | Temperature | 1450°C to 1600°C | Held for full sintering; ±1°C accuracy ensures quality. |

| Cooling | Rate | ≤10°C/min (recommended) | Controlled cooling prevents microcracks and ensures stability. |

| Total Cycle | Time | As low as 25 minutes (fast), varies by material | Depends on zirconia type and settings for optimal results. |

Ready to enhance your dental lab's sintering process with precision and speed? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need fast cycles for high throughput or controlled processes for superior quality, KINTEK has the expertise to deliver. Contact us today to discuss how our furnaces can optimize your workflow and ensure crack-free, durable zirconia restorations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations