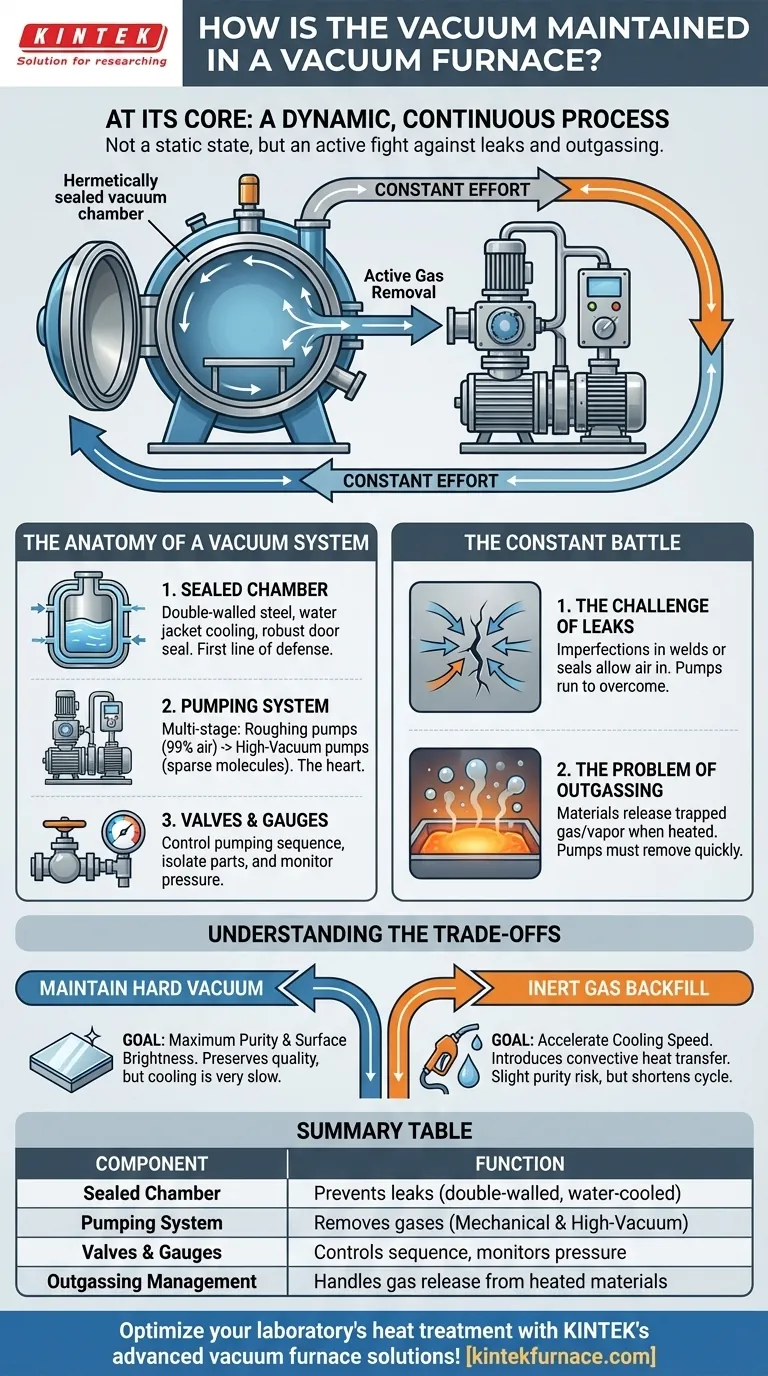

At its core, a vacuum furnace maintains its vacuum through a dynamic and continuous process. A system of powerful vacuum pumps actively removes air and other gases from a hermetically sealed chamber, while the robust construction of the furnace itself prevents the atmosphere from leaking back in. This isn't a one-time event, but a constant effort to counteract any residual gas or new gases released by the material being heated.

The key is to understand that maintaining a vacuum is not a static state, but an active process. It relies on a combination of a physically sealed chamber to minimize leaks and a continuously operating pump system to remove any gases that are present or released during the heating cycle.

The Anatomy of a Vacuum System

A vacuum furnace is more than just a hot box; it is a precisely engineered system where each component plays a critical role in creating and maintaining the vacuum environment.

The Sealed Chamber: The First Line of Defense

The process begins with the physical integrity of the furnace chamber. This chamber is typically a double-walled vessel welded from high-strength steel plates.

This double-wall design often serves as a water jacket, allowing cooling water to circulate. This prevents the outer walls and critical seals from overheating, which is essential for maintaining a reliable vacuum seal throughout high-temperature operations.

The furnace door is a critical moving part that must create a perfect seal. It uses robust mechanisms, like a gear and rack drive, along with specialized O-rings or seals to ensure an airtight closure every time.

The Pumping System: The Heart of the Operation

No chamber is perfectly leak-proof, and materials release gas when heated (a process called outgassing). This is where the vacuum pump system comes in. It's not a single pump, but a series of them working in stages.

- Mechanical & Booster Pumps: These are often called "roughing" pumps. They do the initial heavy lifting, removing the vast majority (over 99%) of the air from the chamber to bring it from atmospheric pressure down to a low vacuum.

- High-Vacuum Pumps: Once the roughing pumps have done their job, a high-vacuum pump takes over. These are typically diffusion pumps or turbo-molecular pumps, which are capable of removing the remaining sparse molecules to achieve very deep vacuum levels.

This multi-stage system is necessary because different pump technologies are efficient at different pressure ranges.

Valves and Gauges: Control and Measurement

The system is controlled by a series of vacuum valves that isolate different parts of the system and control the pumping sequence.

Simultaneously, vacuum measuring devices (gauges) constantly monitor the pressure inside the chamber. This provides the feedback needed to control the pumps and ensure the process parameters are being met precisely.

The Constant Battle for Vacuum

Maintaining a vacuum is an ongoing fight against two primary opponents: physical leaks and gases released from the workpiece itself.

The Challenge of Leaks

Even the smallest imperfection in a weld, a seal, or a fitting can create a leak path for air to enter the furnace. The pump system must run continuously to overcome these leaks and maintain the target pressure. This is why regular maintenance and leak-checking are critical for reliable furnace operation.

The Problem of Outgassing

As materials, especially metals and ceramics, are heated, they release trapped gases and vapors from their surface and bulk. This outgassing can significantly increase the pressure inside the chamber.

The high-vacuum pumps must have enough capacity to remove these released gases as quickly as they appear, ensuring the workpiece remains in a clean, controlled environment.

Understanding the Trade-offs

While a deep vacuum is often the goal, there are operational trade-offs to consider, particularly during the cooling phase.

Purity vs. Cooling Speed

Maintaining a hard vacuum during the cooling cycle preserves the absolute best surface quality and purity of the workpiece. However, a vacuum is an excellent insulator, which means cooling can be very slow.

The Role of Backfilling

To speed up the cooling process, some operations intentionally introduce a small, controlled amount of a high-purity inert gas (like argon or nitrogen) back into the chamber.

This gas provides a medium for convective heat transfer, dramatically accelerating cooling and reducing overall cycle time. The trade-off is a slight risk of minor surface interaction with the gas, but for many applications, the time saved is worth it. This technique also helps in preventing distortion in certain parts.

Making the Right Choice for Your Process

The strategy for maintaining a vacuum depends entirely on the metallurgical goals for the final product.

- If your primary focus is maximum purity and surface brightness: You must maintain a deep and continuous vacuum throughout the entire heating and cooling cycle.

- If your primary focus is balancing cycle time with high quality: Utilize an inert gas backfill during the cooling phase to accelerate heat transfer and shorten your production time.

- If you are troubleshooting poor performance: Begin by inspecting the physical integrity of your chamber seals, then systematically diagnose the efficiency of each pump in your vacuum system.

Ultimately, a vacuum furnace's performance relies on a system working in harmony to actively win the continuous battle against atmospheric pressure.

Summary Table:

| Component | Function |

|---|---|

| Sealed Chamber | Prevents air leaks with double-walled steel and water cooling |

| Pumping System | Removes gases via mechanical and high-vacuum pumps |

| Valves and Gauges | Controls pumping sequence and monitors pressure |

| Outgassing Management | Handles gas release from heated materials |

Optimize your laboratory's heat treatment processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision