In dental furnace operations, vacuum technology is the key to transforming raw materials into high-quality, clinically reliable restorations. It functions by actively removing air and atmospheric gases from the firing chamber. This process eliminates the risk of trapped air bubbles, porosity, and contamination within materials like porcelain or zirconia, ensuring the final restoration is dense, strong, and aesthetically superior.

The core benefit of a vacuum is not merely preventing flaws; it is about creating a controlled, pure environment. This level of control allows for unparalleled process repeatability and ensures the final material properties—like strength and color—are achieved exactly as intended, cycle after cycle.

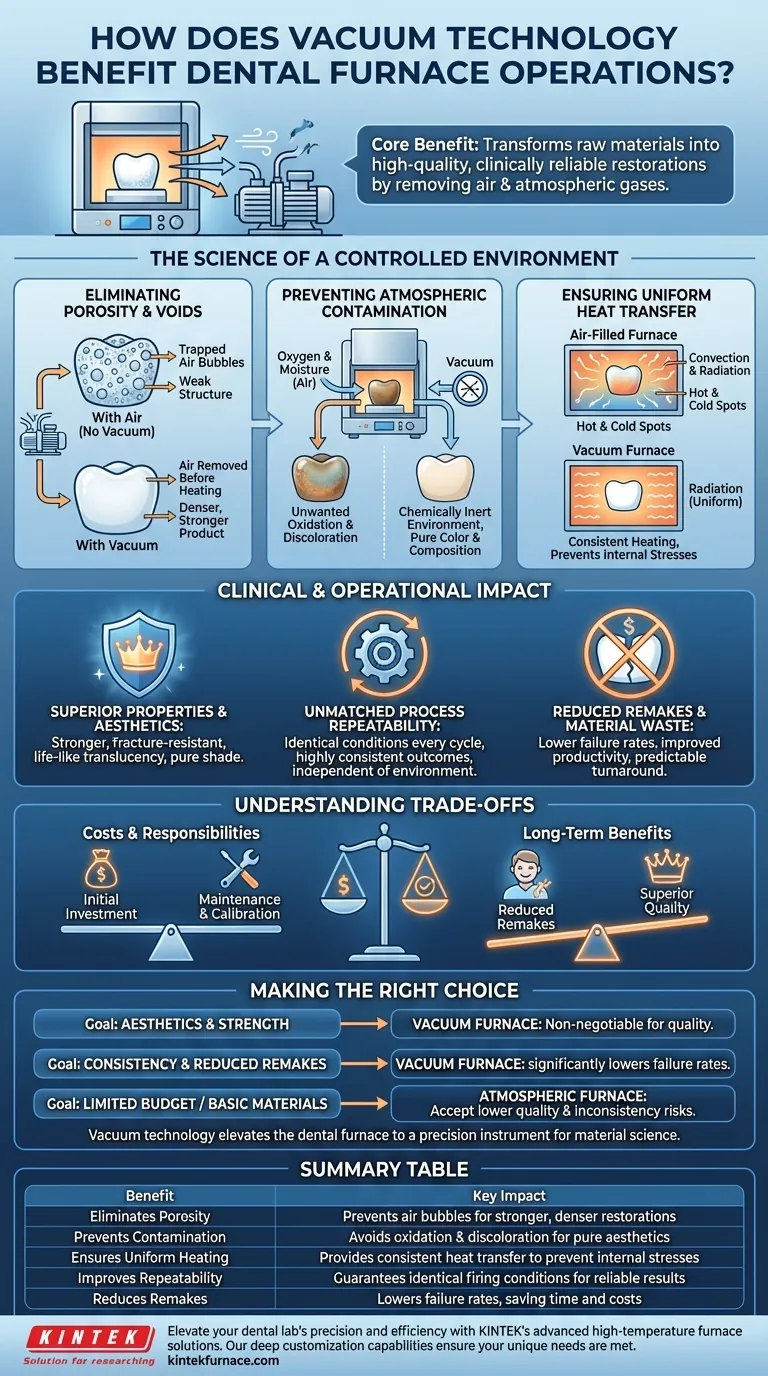

The Science of a Controlled Firing Environment

To understand the benefits, we must first look at what a vacuum removes from the equation: the unpredictable atmosphere. Air is not empty; it contains oxygen, nitrogen, moisture, and other trace elements that can interfere with sensitive dental materials at high temperatures.

Eliminating Porosity and Voids

When porcelain is fired, trapped air expands with heat. If this air cannot escape, it forms bubbles or voids within the restoration, significantly weakening the final structure and creating aesthetic imperfections.

A vacuum pump removes the air from the chamber before the material reaches a temperature where it can trap these expanding gases. This results in a denser, more robust final product.

Preventing Atmospheric Contamination

The oxygen and moisture present in normal air can react with dental ceramics and alloys during the intense heat of a firing or sintering cycle.

These reactions can cause unwanted oxidation and discoloration, leading to poor shade matching and compromised material integrity. By creating a vacuum, you establish a chemically inert environment, ensuring the material's color and composition remain pure and predictable.

Ensuring Uniform Heat Transfer

In an air-filled furnace, heat is transferred through both radiation and convection. Air currents from convection can cause uneven heating, leading to hot and cold spots on the restoration.

In a vacuum, heat transfer occurs primarily through radiation, which is far more uniform. This ensures the entire restoration heats and cools at a consistent rate, which is critical for preventing internal stresses and achieving a complete, even sinter.

The Impact on Clinical and Operational Outcomes

The scientific principles of vacuum firing translate directly into tangible benefits for the dental lab and the patient. Moving beyond theory, this is what a controlled environment delivers in practice.

Superior Material Properties and Aesthetics

A restoration free of porosity is inherently stronger and more resistant to fracture. For aesthetic materials like layered porcelain, the absence of bubbles also means greater translucency and a more life-like appearance. The final shade is purer and more predictable without atmospheric contamination.

Unmatched Process Repeatability

One of the greatest challenges in a dental lab is achieving the exact same result every time. Atmospheric conditions can vary daily based on humidity and pressure, introducing a subtle variable into every firing cycle.

A vacuum furnace eliminates this variable. By firing in a controlled vacuum, you guarantee that the conditions inside the chamber are identical for every cycle, leading to highly consistent and repeatable outcomes.

Reduced Remakes and Material Waste

Failures, whether from cracks, bubbles, or poor shade matching, lead to costly and time-consuming remakes. The consistency and reliability afforded by vacuum technology drastically reduce the rate of these failures.

This not only improves productivity and profitability but also enhances the quality of service by ensuring predictable turnaround times.

Understanding the Trade-offs

While the benefits are clear, adopting vacuum technology requires a realistic understanding of its requirements. Objectivity demands acknowledging the associated costs and responsibilities.

Initial Investment Cost

Furnaces equipped with high-quality vacuum systems represent a greater initial capital investment compared to simpler, atmosphere-only ovens. This cost must be weighed against the long-term savings from reduced remakes and superior quality.

Maintenance and Calibration

A vacuum system is only effective if it works perfectly. The vacuum pump requires regular oil changes or maintenance, and the furnace door seals must be kept clean and intact to prevent leaks. Neglecting this maintenance will negate the benefits of the technology.

Making the Right Choice for Your Goal

The decision to invest in a vacuum furnace should be based on your lab's specific clinical and business objectives.

- If your primary focus is aesthetic quality and material strength: A vacuum furnace is non-negotiable for eliminating porosity and achieving the highest-quality porcelain and zirconia restorations.

- If your primary focus is operational consistency and reducing remakes: The process repeatability offered by a vacuum environment will significantly lower failure rates and improve profitability over time.

- If you are working with a limited budget or only basic materials: An atmospheric furnace may suffice for some tasks, but you must accept the inherent risks of lower quality and inconsistent results.

Ultimately, integrating vacuum technology elevates the dental furnace from a simple oven to a precision instrument for material science.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Eliminates Porosity | Prevents air bubbles for stronger, denser restorations |

| Prevents Contamination | Avoids oxidation and discoloration for pure aesthetics |

| Ensures Uniform Heating | Provides consistent heat transfer to prevent internal stresses |

| Improves Repeatability | Guarantees identical firing conditions for reliable results |

| Reduces Remakes | Lowers failure rates, saving time and costs |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for dental applications. Our deep customization capabilities ensure your unique experimental needs are met, delivering superior restorations with unmatched consistency. Contact us today to discuss how our vacuum furnaces can transform your operations and boost your profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab