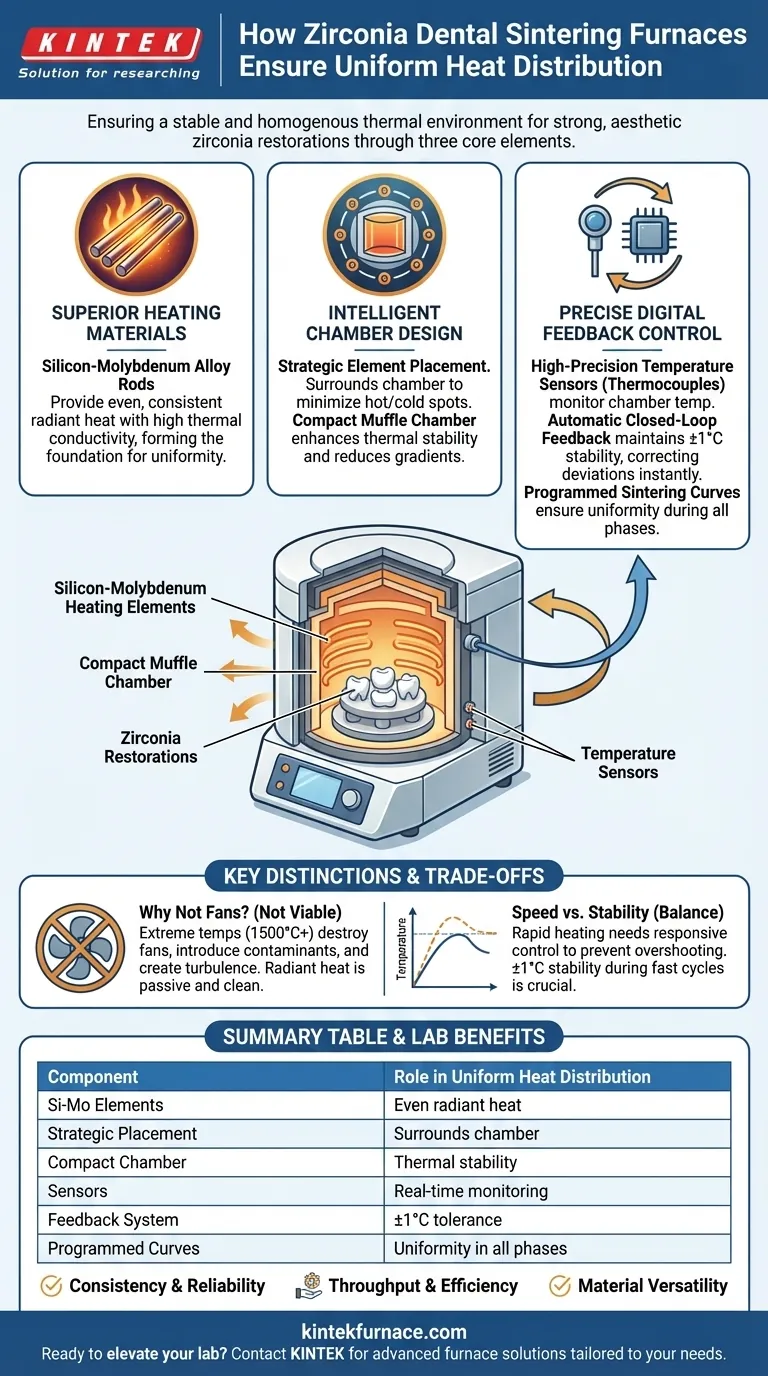

At its core, a Zirconia Dental Sintering Furnace ensures uniform heat distribution through a sophisticated combination of three elements: superior heating materials, intelligent chamber design, and precise digital feedback control. These systems work in concert to create a stable and homogenous thermal environment, which is absolutely critical for producing strong and aesthetically pleasing zirconia restorations.

The challenge of sintering zirconia is not just reaching a high temperature, but holding that temperature evenly across the entire restoration. Uniformity is achieved by integrating high-conductivity heating elements with a closed-loop sensor system that actively eliminates temperature variations in real time.

The Core Components of Uniform Heating

Achieving a homogenous thermal environment at temperatures exceeding 1500°C requires a multi-faceted engineering approach. It begins with the physical construction of the furnace itself.

High-Conductivity Heating Elements

The primary mechanism for generating heat is the use of silicon-molybdenum alloy rods. This specific material is chosen for its ability to withstand extreme temperatures while offering excellent and predictable thermal conductivity.

These high-quality elements radiate heat evenly, acting as the foundation for a uniform temperature profile within the furnace chamber.

Strategic Element Placement

The arrangement of these heating elements is just as important as the material they are made from.

Similar to high-end tube furnaces, the silicon-molybdenum rods are positioned to surround the sintering chamber. This ensures that thermal energy is radiated towards the zirconia restorations from multiple directions, minimizing the potential for hot spots or cold spots.

The Compact Muffle Chamber

The design of the furnace interior, known as the muffle chamber, is optimized for thermal stability.

A compact, well-insulated chamber reduces the total volume that needs to be heated. This makes it easier to achieve and maintain a consistent temperature throughout the space, preventing temperature gradients that could warp or weaken the restoration.

The Role of Intelligent Control Systems

While physical design creates the potential for uniformity, active digital control is what guarantees it throughout the entire, multi-hour sintering cycle.

High-Precision Temperature Sensors

The furnace is equipped with high-precision sensors (typically thermocouples) that constantly monitor the temperature inside the chamber. These sensors are the "eyes" of the system, providing a constant stream of data back to the central controller.

The Automatic Feedback Loop

This is the "brain" of the operation. The furnace controller continuously compares the real-time sensor readings to the desired temperature set by the sintering program.

If it detects even a minor deviation, it instantly adjusts the power output to the heating elements. This closed-loop feedback system is capable of maintaining temperature stability within an extremely tight tolerance, often as precise as ±1°C.

Programmed Sintering Curves

Modern furnaces allow for complex, multi-stage heating programs or "curves." The control system ensures that heat remains uniform not only at the peak sintering temperature but also during the critical ramp-up and cool-down phases.

This level of control is essential for achieving the desired material properties, such as translucency and flexural strength.

Understanding Key Distinctions and Trade-offs

Not all furnaces achieve temperature uniformity in the same way. Understanding the differences is key to evaluating equipment for this specific, high-temperature application.

Why Not Use Fans? The Challenge of High Temperatures

Some lower-temperature equipment, like annealing furnaces, use fans to circulate air and force thermal uniformity. This method is not viable for zirconia sintering.

The extreme temperatures (often 1500°C or higher) would destroy mechanical fans. Furthermore, forced air circulation could introduce contaminants and create turbulence, negatively impacting the delicate sintering process. Zirconia furnaces rely on passive, radiant heat for a clean and stable environment.

The Balance Between Speed and Stability

Many furnaces boast a rapid heating rate, such as 150°C per minute. While this speed improves lab throughput, it places immense demand on the control system.

Without an exceptionally responsive feedback loop, rapid heating can cause the temperature to overshoot the target, compromising the sintering cycle. The furnace's ability to maintain its ±1°C stability during this rapid ramp-up is a true test of its quality.

What This Means for Your Dental Lab

Understanding how a furnace achieves thermal uniformity allows you to look beyond marketing claims and evaluate the technology that truly impacts your outcomes.

- If your primary focus is consistency and reliability: The combination of silicon-molybdenum elements and a high-precision (±1°C) feedback control system is the most critical feature set to verify.

- If your primary focus is throughput and efficiency: Assess the furnace's heating rate, but confirm it is paired with a responsive control system that prevents temperature overshooting during fast cycles.

- If your primary focus is material versatility: Look for a furnace with fully customizable programming that allows you to build sintering curves tailored to the specific requirements of different zirconia materials.

Ultimately, a deep understanding of these heating principles empowers you to select and operate equipment that delivers predictable, high-quality restorations every time.

Summary Table:

| Component | Role in Uniform Heat Distribution |

|---|---|

| Silicon-Molybdenum Heating Elements | Provide even radiant heat with high conductivity |

| Strategic Element Placement | Surrounds chamber to minimize hot/cold spots |

| Compact Muffle Chamber | Enhances thermal stability and reduces gradients |

| High-Precision Sensors | Monitor temperature for real-time adjustments |

| Closed-Loop Feedback System | Maintains temperature within ±1°C tolerance |

| Programmed Sintering Curves | Ensure uniformity during ramp-up and cool-down phases |

Ready to elevate your dental lab's precision and efficiency? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for diverse laboratory needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we can precisely meet your unique experimental requirements for zirconia sintering and more. Contact us today to discuss how our furnaces can deliver consistent, high-quality results for your dental restorations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique