At its core, a muffle design benefits sample processing by creating a physical barrier between the heating elements and the sample itself. This separation is the key to preventing chemical contamination, ensuring the sample's purity remains intact, and allowing for precise, uniform temperature control within a contained environment.

The fundamental advantage of a muffle furnace is process isolation. By separating the heat source from the sample, it creates an exceptionally pure and stable environment, prioritizing sample integrity over raw heating speed or energy efficiency.

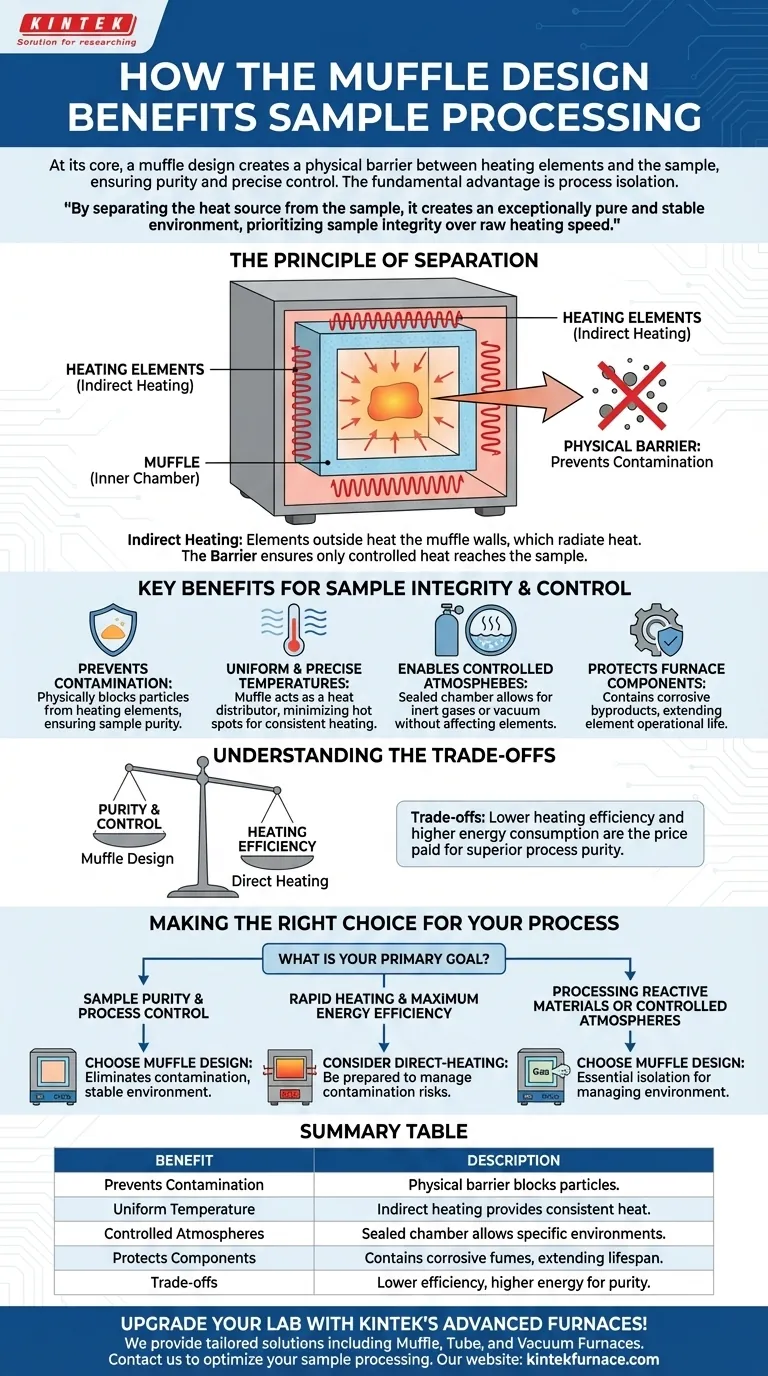

The Principle of Separation: How a Muffle Works

A muffle furnace is not defined by its temperature, but by its internal architecture. The central component is the "muffle," which is a dedicated inner chamber that holds the sample.

What is a Muffle?

The muffle is essentially a box-like enclosure made from a chemically resistant and thermally stable material, such as alumina or other refractory ceramics. This chamber sits inside the main furnace body.

The Role of Indirect Heating

Heating elements are positioned on the outside of the muffle chamber. They heat the muffle's walls, and that heat then radiates evenly into the sample chamber. This indirect heating method is the defining characteristic of the design.

The Importance of the Barrier

This physical barrier is the source of all the design's primary benefits. It ensures that the only thing the sample is exposed to is controlled, radiant heat and the specific atmosphere you introduce, not the raw energy or potential contaminants from the heating elements.

Key Benefits for Sample Integrity and Control

The muffle's separation directly translates into superior process control, which is critical for scientific and industrial applications where repeatability and purity are paramount.

Preventing Sample Contamination

Without a muffle, particles from the heating elements can flake off and fall into the sample, altering its chemical composition. The muffle design physically blocks this from happening, guaranteeing a higher degree of sample purity.

Ensuring Uniform and Precise Temperatures

Because the entire muffle chamber is heated from the outside, it acts as a heat distributor. This geometry and the material properties of the muffle ensure that heat is distributed evenly, minimizing hot spots and providing uniform, consistent heating across the entire sample.

Enabling Controlled Atmospheres

The sealed nature of the muffle chamber makes it ideal for processes that require a specific environment. You can introduce inert gases to prevent oxidation or even create a vacuum, all without that atmosphere affecting or being affected by the external heating elements.

Protecting Furnace Components

The barrier works both ways. Corrosive fumes or byproducts released from a sample during heating are contained within the muffle. This protects the expensive and sensitive heating elements from chemical attack, extending the operational life of the furnace.

Understanding the Trade-offs

No design is perfect for every application. The isolation provided by a muffle introduces specific trade-offs related to performance and energy use.

Heating Efficiency vs. Purity

The primary trade-off is efficiency. Because heat must first transfer through the muffle wall to reach the sample, the process is inherently less efficient than a direct-heating furnace where elements are in the same chamber. This is the price paid for process purity.

Increased Energy Consumption

As a direct consequence of lower heating efficiency, muffle furnaces generally consume more energy to reach and maintain a target temperature. The thick insulation helps mitigate heat loss, but the indirect heating path remains a point of inefficiency.

Making the Right Choice for Your Process

Selecting the right furnace depends entirely on your primary processing goal. The muffle design excels where control and purity are non-negotiable.

- If your primary focus is sample purity and process control: The muffle design is the superior choice, as it eliminates contamination from heating elements and provides a highly stable, uniform thermal environment.

- If your primary focus is rapid heating and maximum energy efficiency: A direct-heating furnace may be more suitable, but you must be prepared to manage the risk of sample interaction with the furnace elements.

- If your primary focus is processing reactive materials or using controlled atmospheres: The muffle design provides the essential isolation needed to manage the chamber's environment without damaging the furnace's core components.

Ultimately, choosing a muffle furnace is a deliberate decision to prioritize the quality and integrity of your final sample above all else.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Contamination | Physical barrier blocks heating element particles, ensuring sample purity. |

| Uniform Temperature | Indirect heating provides consistent, even heat distribution. |

| Controlled Atmospheres | Sealed chamber allows use of inert gases or vacuum for specific environments. |

| Protects Components | Contains corrosive fumes, extending furnace lifespan. |

| Trade-offs | Lower heating efficiency and higher energy consumption for purity. |

Upgrade your lab with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing sample integrity and process control. Contact us today to discuss how we can optimize your sample processing!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide