At its core, an induction furnace works by using a powerful, fluctuating magnetic field to turn a piece of metal into its own heat source. An alternating electric current is passed through a copper coil, which generates the magnetic field. This field induces strong electrical currents, called eddy currents, directly within the metal, and the metal's natural resistance to these currents generates intense, precise heat that causes it to melt.

The fundamental principle is contactless heating through electromagnetic induction. Unlike a conventional furnace that heats from the outside, an induction furnace generates heat inside the material itself, providing unparalleled speed, cleanliness, and control over the melting process.

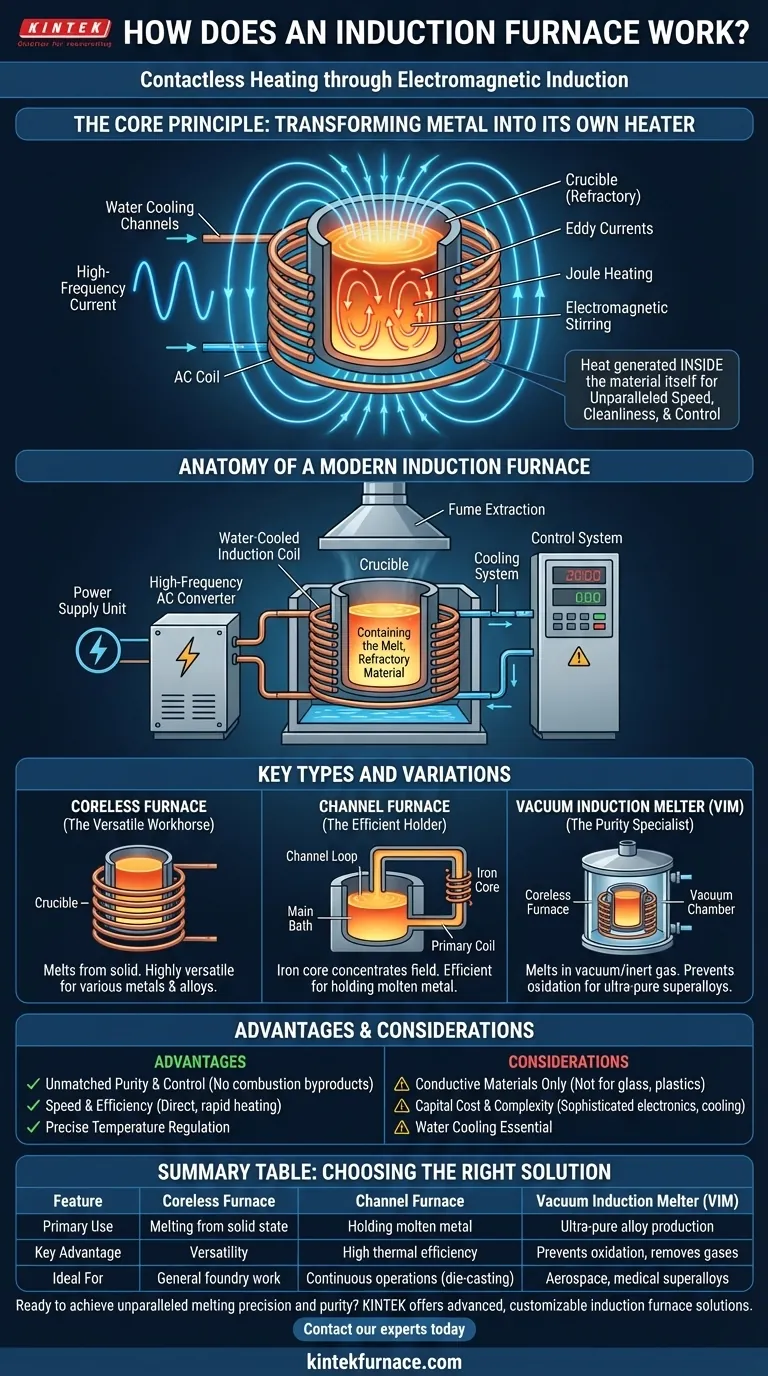

The Core Principle: Transforming Metal into Its Own Heater

The genius of the induction furnace lies in its application of two fundamental physics principles: Faraday's Law of Induction and Joule's Law of heating.

The AC Coil and the Magnetic Field

The process begins with the induction coil, typically made of hollow copper tubing. A high-frequency alternating current (AC) is passed through this coil, which itself is cooled by circulating water.

This AC current generates a powerful and rapidly changing magnetic field in the space within and around the coil.

Inducing the Eddy Currents

The material to be melted, known as the charge, is placed inside a crucible within the coil. Because the charge is electrically conductive (i.e., a metal), the fluctuating magnetic field induces small, circular electrical currents throughout its volume.

These induced currents are called eddy currents.

Resistive Heating (Joule's Law)

All metals have some inherent electrical resistance. As the strong eddy currents flow through the metal against this resistance, they dissipate energy in the form of heat.

This phenomenon, known as Joule heating, raises the temperature of the charge rapidly and efficiently, eventually bringing it to its melting point. The heat is generated internally, not transferred from an external source.

The Inherent Stirring Action

A valuable side effect of the electromagnetic forces is a natural stirring of the molten metal. This electromagnetic stirring ensures the liquid bath is constantly moving, which is critical for creating homogenous alloys with a uniform chemical composition and temperature.

Anatomy of a Modern Induction Furnace

While the principle is elegant, a functional furnace relies on several integrated systems working together.

The Crucible: Containing the Melt

The crucible is the non-reactive container that holds the metal charge. It must be made of a material, known as a refractory, that can withstand extreme temperatures.

Commonly, crucibles are made of ceramics, which are non-conductive. In this setup, the magnetic field passes through the crucible and heats the metal charge directly.

The Induction Coil: The Engine of the Furnace

This water-cooled copper coil is the heart of the system. It is carefully shaped to surround the crucible and efficiently couple its magnetic field with the charge material.

The need for water cooling is critical, as the coil's own electrical resistance would otherwise cause it to overheat and fail.

The Power Supply: Delivering High-Frequency Current

Standard grid electricity is not suitable for induction heating. A sophisticated power supply unit, consisting of transformers and an inverter, converts the input power to the high-frequency AC required to generate the powerful magnetic field.

Supporting Systems: Control, Cooling, and Safety

Modern furnaces include precise process controls to monitor and regulate temperature. They also integrate robust cooling systems for the coil and power electronics, as well as fume extraction equipment to manage any vapors produced during melting.

Key Types and Variations

Induction technology is adapted for different scales and applications, leading to a few primary designs.

The Coreless Furnace: The Versatile Workhorse

This is the most common design, where a refractory crucible is placed directly inside the induction coil. Its name comes from the absence of an iron core to concentrate the magnetic field.

Coreless furnaces are highly versatile, capable of melting a wide range of metals and alloys from a cold, solid state.

The Channel Furnace: The Efficient Holder

A channel furnace operates more like a transformer. It has a main well of molten metal connected to a smaller loop or "channel" that passes through an iron core and a primary coil.

The molten metal in the channel acts as a single-turn secondary coil, heating up and circulating back into the main bath. These furnaces are extremely efficient for holding large volumes of metal at temperature or for melting low-temperature alloys.

The Vacuum Induction Melter (VIM): The Purity Specialist

A VIM is not a fundamentally different heating method, but a coreless furnace housed inside a chamber from which all air is removed.

By melting in a vacuum or a controlled inert gas atmosphere, this process prevents the molten metal from reacting with oxygen and other atmospheric contaminants. This is essential for producing the ultra-pure, high-performance superalloys used in aerospace and medical applications.

Understanding the Trade-offs and Advantages

No technology is perfect for every situation. The choice to use an induction furnace is based on a clear set of benefits and considerations.

Advantage: Unmatched Purity and Control

Because there is no burning fuel, there are no combustion byproducts to contaminate the melt. This cleanliness, combined with precise temperature regulation and the option for vacuum melting, results in alloys of the highest quality and purity.

Advantage: Speed and Efficiency

Heating is direct, rapid, and starts the moment the power is turned on. Energy is transferred directly to the metal with high efficiency, minimizing waste heat and creating a more comfortable working environment.

Limitation: Conductive Materials Only

The entire principle relies on inducing current in the charge. Therefore, induction furnaces can only be used to heat electrically conductive materials. They are ineffective for melting glasses, plastics, or other insulators.

Consideration: Capital Cost and Complexity

The sophisticated power electronics, control systems, and water-cooling infrastructure make induction furnaces a more significant capital investment than simpler, fuel-fired alternatives.

Making the Right Choice for Your Goal

The specific type of induction furnace you would use is dictated entirely by the final material requirements.

- If your primary focus is creating high-performance, ultra-pure superalloys for critical applications: A Vacuum Induction Melter (VIM) is the essential choice to prevent oxidation and remove dissolved gases.

- If your primary focus is melting a wide variety of metals and alloys from a solid state: The standard coreless induction furnace offers the most versatility for general-purpose foundry and metallurgical work.

- If your primary focus is holding large volumes of molten metal efficiently at a specific temperature: A channel furnace provides excellent thermal efficiency for continuous operation in applications like die-casting or large foundries.

Understanding this principle of internal, contactless heating is the key to appreciating why induction furnaces are central to modern, high-precision metallurgy.

Summary Table:

| Feature | Coreless Furnace | Channel Furnace | Vacuum Induction Melter (VIM) |

|---|---|---|---|

| Primary Use | Melting from solid state | Holding molten metal | Ultra-pure alloy production |

| Key Advantage | Versatility for various metals | High thermal efficiency | Prevents oxidation, removes gases |

| Ideal For | General foundry work | Continuous operations (e.g., die-casting) | Aerospace, medical superalloys |

Ready to achieve unparalleled melting precision and purity? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced induction furnace solutions tailored for your lab's unique needs. Whether you require the versatility of a Coreless Furnace, the efficiency of a Channel Furnace, or the ultra-clean environment of a Vacuum Induction Melter, our deep customization capabilities ensure your specific experimental and production goals are met. Contact our experts today to discuss how our induction technology can transform your metallurgical processes!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials