At its core, induction heating improves quality control by transforming the heating process from an external, often inconsistent art into an internal, highly repeatable science. It provides precise, targeted energy exactly where it's needed, minimizing inconsistencies and virtually eliminating common defects caused by uneven temperature distribution or overheating.

The primary advantage of induction is not just heating faster or more efficiently, but achieving unprecedented repeatability. By directly controlling the electromagnetic field, you gain direct control over the heat generated within the part itself, ensuring every single product in a batch receives the exact same thermal treatment.

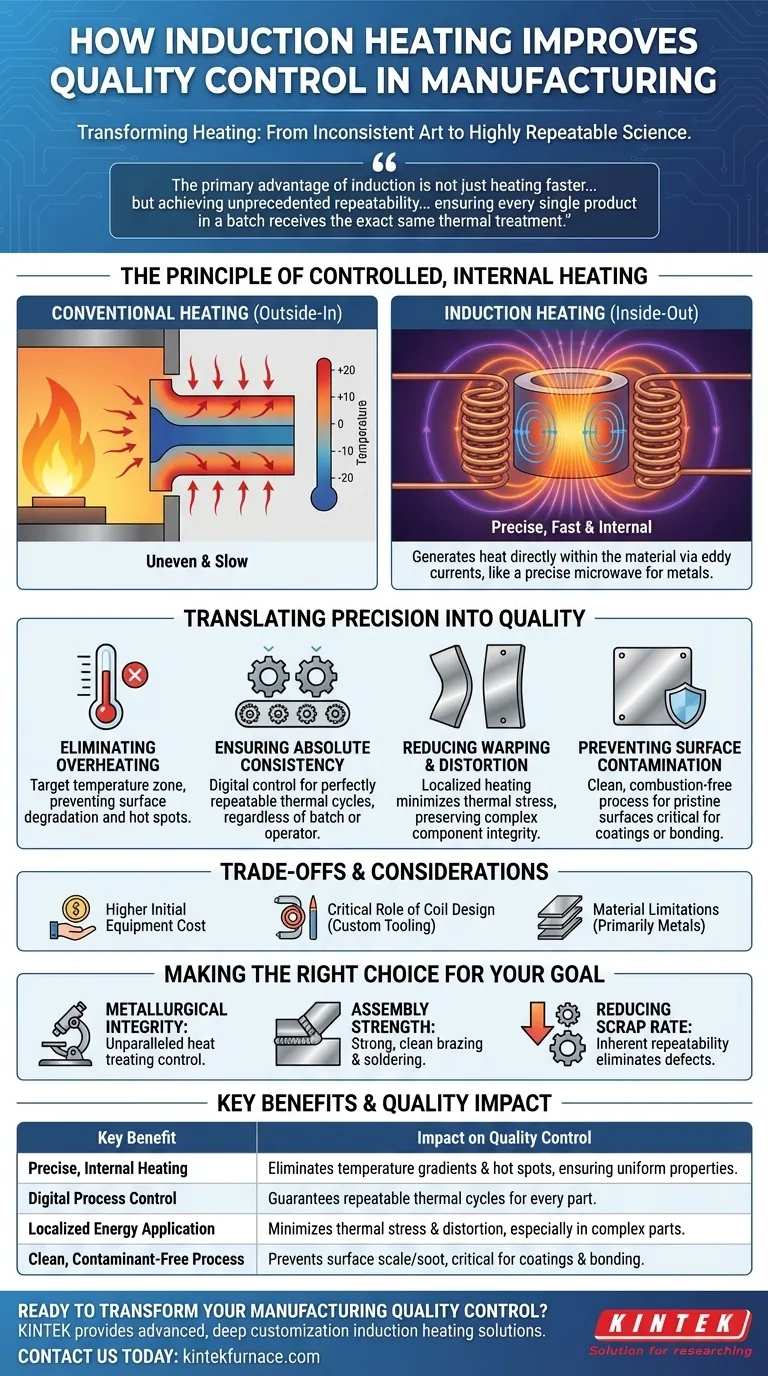

The Principle of Controlled, Internal Heating

To understand how induction improves quality, you must first understand why it is fundamentally different from traditional heating methods like furnaces or torches.

How Induction Differs from Conventional Heating

Conventional methods heat a part from the outside-in using convection or radiation. This process is slow and often creates an uneven temperature gradient between the surface and the core of the material.

Induction heating works from the inside-out. It functions like a precise, high-powered microwave for metals, generating heat directly within the material itself.

The Role of the Electromagnetic Field

An induction system uses an alternating electrical current flowing through a carefully designed copper coil. This current generates a concentrated, oscillating magnetic field around the coil.

When a conductive part (like steel or aluminum) is placed within this field, the process of heating begins without any physical contact.

Generating Heat from Within the Part

The magnetic field induces electrical currents, known as eddy currents, to flow inside the workpiece. The material's natural resistance to these currents generates instantaneous and localized heat.

Because the heat is generated by the part itself, the process is incredibly fast, efficient, and—most importantly for quality control—exceptionally controllable.

Translating Precision into Quality

This unique heating mechanism directly solves many of the most common sources of defects and quality variance found in manufacturing.

Eliminating Overheating and Hot Spots

Since heat is generated internally, you can bring a specific zone to the target temperature without superheating the part's surface. This prevents the degradation of material properties, a common problem with flame heating.

Ensuring Absolute Temperature Consistency

Modern induction power supplies allow for precise digital control over the current, voltage, and frequency of the field. This means you can create a perfectly repeatable thermal cycle that is identical for every part, regardless of batch size or operator skill.

Reducing Warping and Distortion

By heating only the required area, induction minimizes the thermal stress across the entire component. This dramatically reduces the risk of warping and distortion, especially in complex or thin-walled parts.

Preventing Surface Contamination

Induction is a perfectly clean process. Unlike fuel-fired furnaces, it produces no combustion byproducts like soot or scale. This ensures a pristine surface, which is critical for subsequent processes like coating, plating, or high-strength bonding.

Understanding the Trade-offs and Considerations

While powerful, induction heating is not a universal solution. Acknowledging its specific requirements is key to a successful implementation.

Initial Equipment Cost

The capital investment for an induction heating system is typically higher than for a simple torch setup or a conventional oven. This cost is often justified by reduced scrap rates, higher throughput, and lower energy consumption over time.

The Critical Role of Coil Design

The induction coil is not a generic part; it is a piece of custom tooling. It must be engineered to match the geometry of your workpiece to create the precise magnetic field required for effective heating. Poor coil design leads to poor results.

Material Limitations

Induction heating works directly only on electrically conductive materials, primarily metals. Non-conductive materials like plastics or ceramics can be heated indirectly using a conductive "susceptor," but the process is less efficient.

Making the Right Choice for Your Goal

The decision to adopt induction should be driven by your specific quality objectives.

- If your primary focus is metallurgical integrity: Induction offers unparalleled control for heat treating, ensuring consistent hardness and case depth without compromising the core material.

- If your primary focus is assembly strength: Use induction for brazing or soldering to create strong, clean joints by precisely heating only the joint area, preventing thermal damage to nearby components.

- If your primary focus is reducing scrap rate: The inherent repeatability of induction virtually eliminates defects from inconsistent heating, dramatically lowering scrap and rework costs.

By mastering the flow of energy within the material itself, induction heating gives you ultimate control over the quality and consistency of your final product.

Summary Table:

| Key Benefit | Impact on Quality Control |

|---|---|

| Precise, Internal Heating | Eliminates temperature gradients and hot spots, ensuring uniform material properties. |

| Digital Process Control | Guarantees repeatable thermal cycles for every part, independent of operator skill. |

| Localized Energy Application | Minimizes thermal stress and distortion, especially in complex or thin-walled components. |

| Clean, Contaminant-Free Process | Prevents surface scale or soot, critical for coatings, plating, or high-strength bonding. |

Ready to Transform Your Manufacturing Quality Control?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse industries with advanced induction heating solutions. Our product line, including custom-designed induction coils and systems, is complemented by our strong deep customization capability to precisely meet your unique production requirements—ensuring you achieve the ultimate in repeatability, efficiency, and defect reduction.

Contact us today to discuss how our induction heating technology can solve your specific quality challenges and boost your bottom line.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability