Fundamentally, induction heating ensures repeatability by removing external variables and turning the heating process into a precise, digitally controlled electrical function. Because the heat is generated directly within the material by a controllable magnetic field, the process is governed by stable physical laws, not the fluctuating conditions of a conventional furnace.

Conventional heating methods struggle with consistency because they rely on transferring heat from an external source. Induction heating achieves superior repeatability by generating heat inside the part itself using a precisely controlled electromagnetic field, making the outcome dependent on stable electrical parameters, not a variable environment.

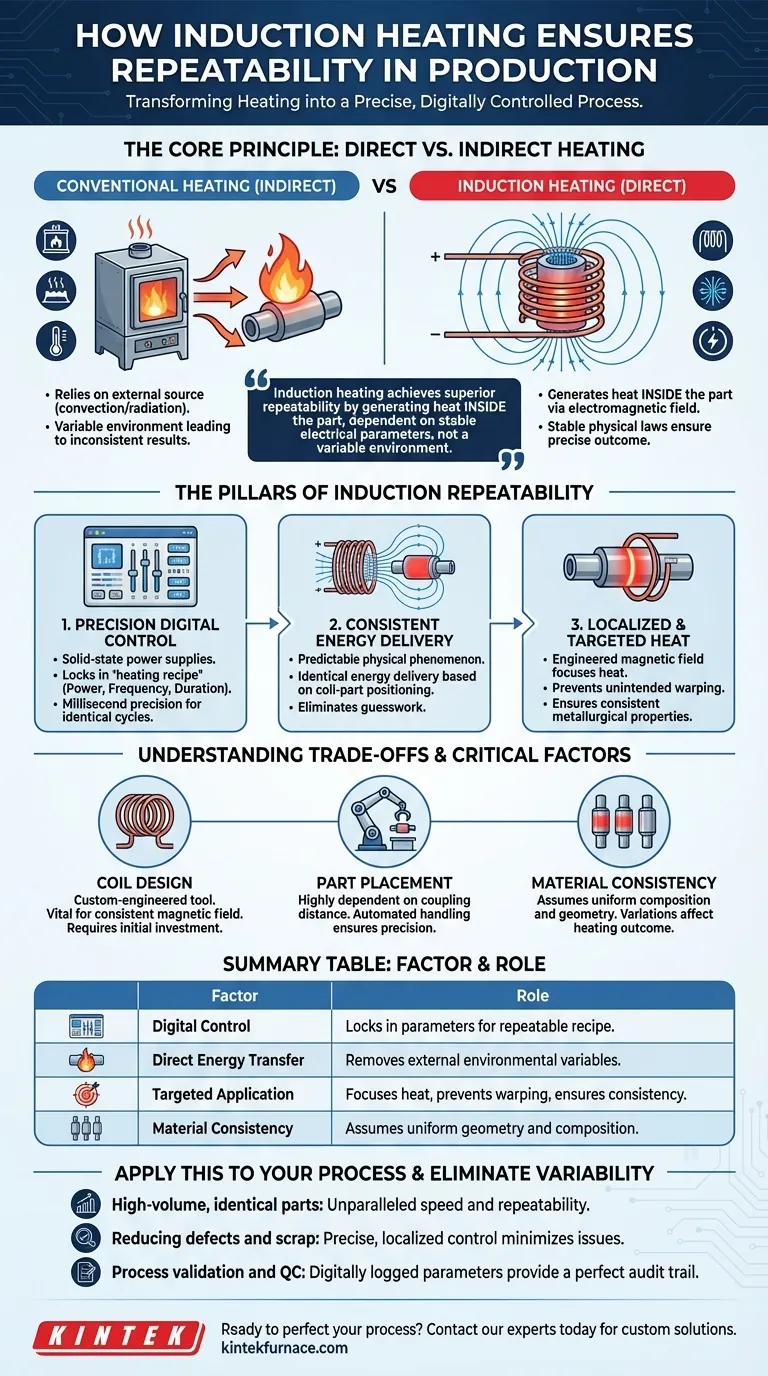

The Core Principle: Direct vs. Indirect Heating

To understand induction's repeatability, we must first contrast it with traditional methods. The key difference lies in where and how the heat is generated.

The Challenge of Conventional Heating

Traditional methods, like furnaces or flames, heat a part from the outside in. This process relies on convection and radiation to transfer thermal energy.

This indirect method is prone to inconsistencies. Factors like ambient temperature, airflow, burner performance, and the time it takes for heat to soak through the material can all vary, leading to different results from one part to the next.

The Physics of Induction Control

Induction heating uses a non-contact method to generate heat directly inside the electrically conductive workpiece. This is achieved through two primary physical phenomena:

- Joule Heating: An alternating current in the induction coil creates a magnetic field, which in turn induces an electrical current within the part. The material's natural resistance to this current flow generates precise and rapid heat.

- Magnetic Hysteresis: In magnetic materials like steel, the rapidly changing magnetic field causes internal friction as the material's magnetic domains resist reorientation. This friction also creates uniform internal heat.

Because the heat originates within the material, the process is instantaneous and not dependent on slow, variable thermal transfer from the outside.

The Pillars of Induction Repeatability

The physical principles of induction are translated into a repeatable manufacturing process through three key factors: precise control, consistent energy delivery, and targeted application.

1. Precision Digital Control

Modern induction heating systems are managed by solid-state power supplies. These allow operators to set and lock a specific "heating recipe."

Key parameters like power level, frequency of the current, and heating duration are controlled digitally with millisecond precision. Once a process is validated for a specific part, the exact same cycle can be executed millions of times without deviation.

2. Consistent Energy Delivery

The magnetic field that delivers the energy is a predictable physical phenomenon. As long as the part is placed in the same position relative to the induction coil, it will receive the exact same amount of energy, in the exact same location, every single time.

This removes the guesswork and variability associated with hot or cold spots in a furnace or the fluctuating intensity of a flame.

3. Localized and Targeted Heat

The induction coil is engineered to shape the magnetic field, allowing heat to be applied only to a specific area of the part.

This precision prevents unintended consequences like the warping or softening of adjacent areas. By controlling exactly where the heat is generated, you ensure that the metallurgical properties you desire are created consistently in the right place on every part.

Understanding the Trade-offs

While powerful, achieving perfect repeatability with induction heating requires attention to certain critical factors. Ignoring them can undermine the consistency of the process.

The Critical Role of Coil Design

The induction coil is not a generic component; it is a custom-engineered tool. A poorly designed or constructed coil will produce an inconsistent magnetic field, leading to uneven heating and unreliable results. The initial investment in proper coil design is paramount.

Sensitivity to Part Placement

The efficiency of energy transfer is highly dependent on the distance between the part and the coil (known as coupling). For maximum repeatability, especially in high-volume production, automated part-handling is often necessary to ensure every workpiece is positioned with identical precision.

Material Consistency is Assumed

The induction process assumes that every workpiece has the same chemical composition, mass, and geometry. Any significant variation in the parts themselves will result in a different heating outcome, as the material's properties directly influence how it interacts with the magnetic field.

How to Apply This to Your Process

Your specific goal will determine which aspect of induction's repeatability is most critical to your operation.

- If your primary focus is high-volume, identical parts: Induction is an unparalleled solution for its speed and repeatability once the initial coil design and automation are perfected.

- If your primary focus is reducing defects and scrap: The precise, localized control of induction minimizes issues like overheating and distortion, directly improving part quality and overall yield.

- If your primary focus is process validation and quality control: Induction's digitally logged parameters provide a perfect audit trail, allowing you to prove that every part in a batch was processed identically.

By mastering these controllable electrical parameters, you move from managing heating variability to eliminating it entirely.

Summary Table:

| Factor | Role in Ensuring Repeatability |

|---|---|

| Digital Control | Locks in power, frequency, and time for a repeatable "heating recipe." |

| Direct Energy Transfer | Heat is generated inside the part, removing external environmental variables. |

| Targeted Application | Custom coils focus heat precisely, preventing warping and ensuring consistent results. |

| Material Consistency | Assumes uniform part geometry and composition for predictable outcomes. |

Ready to Eliminate Process Variability in Your Production?

KINTEK's advanced high-temperature furnace solutions, including our precisely controlled Atmosphere Furnaces, leverage the same principles of repeatability and control as induction heating. Our exceptional R&D and in-house manufacturing capabilities allow us to provide deep customization to meet your unique thermal processing requirements, ensuring consistent, high-quality results batch after batch.

Contact our experts today to discuss how we can engineer a solution to perfect your process.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions