At its core, a zirconia sintering furnace is a specialized high-temperature oven that transforms a soft, chalk-like zirconia block into a dense, super-strong ceramic. It accomplishes this through a highly controlled heating and cooling cycle, where precise temperature management is used to fuse the material’s particles together, radically increasing its strength and altering its aesthetic properties.

The critical insight is that the furnace's function is not merely to apply heat, but to execute a pre-programmed temperature profile with extreme precision. The rate of heating, the duration at peak temperature, and the rate of cooling are all equally important for achieving the final desired strength, fit, and translucency.

The Fundamental Principle: From Porous to Perfect

To understand how the furnace works, you must first grasp the process it is designed to facilitate: sintering. This is the foundation upon which the technology is built.

What is Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat—and sometimes pressure—without melting it to the point of liquefaction.

Think of it like a dense snowbank left for several days. Even without melting, the individual snowflakes begin to bond, and the bank slowly compacts into a more solid block of ice. Sintering applies this same principle to ceramic particles, using high temperatures to dramatically accelerate the bonding process.

Why Zirconia Must Be Sintered

Zirconia used for dental restorations or jewelry starts in a "green" or pre-sintered state. It is soft, porous, and easy to mill into a precise shape.

However, in this state, it is mechanically weak. The sintering process eliminates the porosity, causing the particles to fuse and the object to shrink and densify. This transformation imparts the exceptional strength and durability for which zirconia is known.

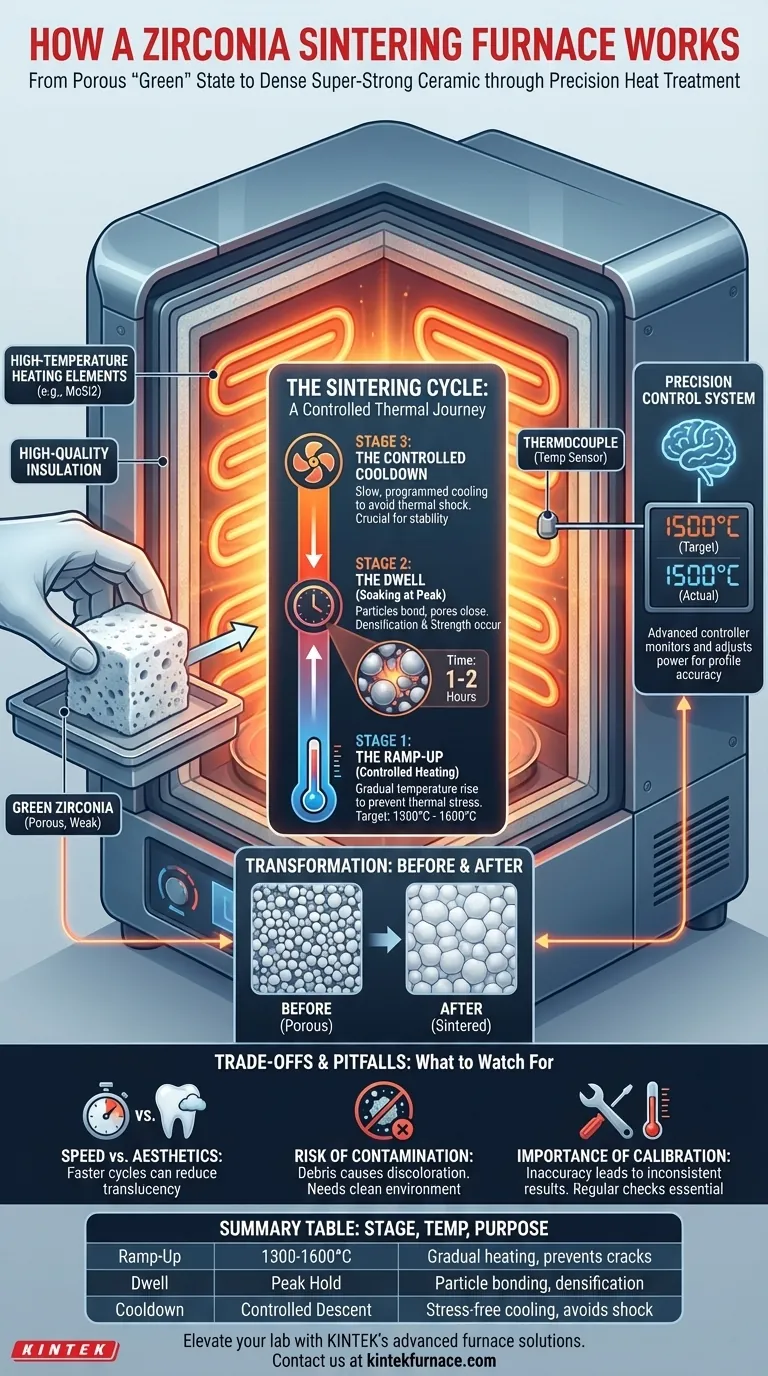

Deconstructing the Sintering Cycle

A typical sintering cycle is a carefully choreographed sequence of temperature changes. Each stage has a distinct and critical purpose.

Stage 1: The Ramp-Up (Heating)

The cycle begins by loading the zirconia restoration into the furnace chamber. The heating elements, typically made of molybdenum disilicide (MoSi2) or silicon carbide (SiC), begin to gradually raise the temperature.

This ramp-up must be controlled and steady. Heating too quickly can introduce thermal stress, which may cause cracks or fractures before the material has a chance to strengthen. The target temperature is usually between 1300°C and 1600°C.

Stage 2: The Dwell (Soaking)

Once the furnace reaches its target temperature, it holds it there for a specified period. This is the "dwell" or "soaking" stage, and it is where the most critical transformation occurs.

During this time, the particles bond at their contact points, and the pores between them shrink and close. This is what causes the material to densify and achieve its final high strength. The length of the dwell time directly impacts the final properties of the zirconia.

Stage 3: The Controlled Cooldown

After the dwell stage is complete, the furnace begins to cool down. This is not a passive process; the furnace controls the rate of cooling very carefully.

Cooling too rapidly would create immense internal stress (thermal shock), causing the newly densified and strong material to crack. A slow, programmed cooldown ensures the final part is stable and stress-free.

Key Components for Precision Control

The furnace's ability to execute this cycle flawlessly depends on several key components working in concert.

High-Temperature Heating Elements

These are the engine of the furnace, responsible for generating the intense heat required for sintering. MoSi2 rods are common due to their ability to perform reliably at very high temperatures in an air atmosphere.

Advanced Temperature Control System

This is the brain of the operation. It consists of a thermocouple, which acts as a highly accurate temperature sensor inside the chamber, and a programmable controller. The controller constantly compares the thermocouple's reading to the programmed cycle and adjusts power to the heating elements to stay on profile.

High-Quality Insulation

To maintain stable temperatures and operate efficiently, the furnace chamber is lined with high-purity ceramic fiber insulation. This minimizes heat loss and ensures the temperature is uniform throughout the chamber, so all parts of the restoration sinter evenly.

Understanding the Trade-offs and Pitfalls

While the process is automated, understanding the variables is key to avoiding common failures and optimizing results.

Speed vs. Final Aesthetics

Many modern furnaces offer "speed sintering" cycles that significantly reduce the total process time. While efficient, these faster cycles can sometimes result in lower translucency compared to a slower, conventional cycle.

The trade-off is between production throughput and achieving the highest possible aesthetic result. The choice depends on the specific type of zirconia and the clinical or aesthetic demands of the case.

The Risk of Contamination

Zirconia sintering is highly sensitive to contamination. Any foreign debris in the furnace chamber, on the sintering tray, or on the restoration itself can cause discoloration or a weak spot in the final product. A meticulously clean environment is non-negotiable.

The Importance of Calibration

The accuracy of the thermocouple can drift over time. An uncalibrated furnace that is running hotter or colder than its display indicates will produce inconsistent results, from under-sintered (weak) to over-sintered (brittle or distorted) restorations. Regular calibration is essential for reproducibility.

Making the Right Choice for Your Goal

Your approach to sintering should align directly with your desired outcome.

- If your primary focus is maximum strength and aesthetics: Use a manufacturer-recommended conventional (longer) sintering cycle to ensure complete densification and optimal translucency.

- If your primary focus is high production throughput: Utilize a validated speed sintering program, but test the results to ensure they meet your quality standards for fit and shade.

- If your primary focus is consistency and reliability: Prioritize a strict schedule for furnace cleaning and professional calibration to guarantee predictable results with every cycle.

Mastering the principles of the sintering process is the final, critical step in unlocking the full potential of this remarkable material.

Summary Table:

| Stage | Temperature Range | Purpose |

|---|---|---|

| Ramp-Up | 1300°C to 1600°C | Gradual heating to prevent cracks |

| Dwell | Peak temperature hold | Particle bonding and densification |

| Cooldown | Controlled descent | Stress-free cooling to avoid thermal shock |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for diverse labs. Our strong deep customization ensures precise alignment with your unique experimental needs, delivering reliable performance and enhanced efficiency. Contact us today to discuss how our furnaces can optimize your sintering processes and achieve superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab