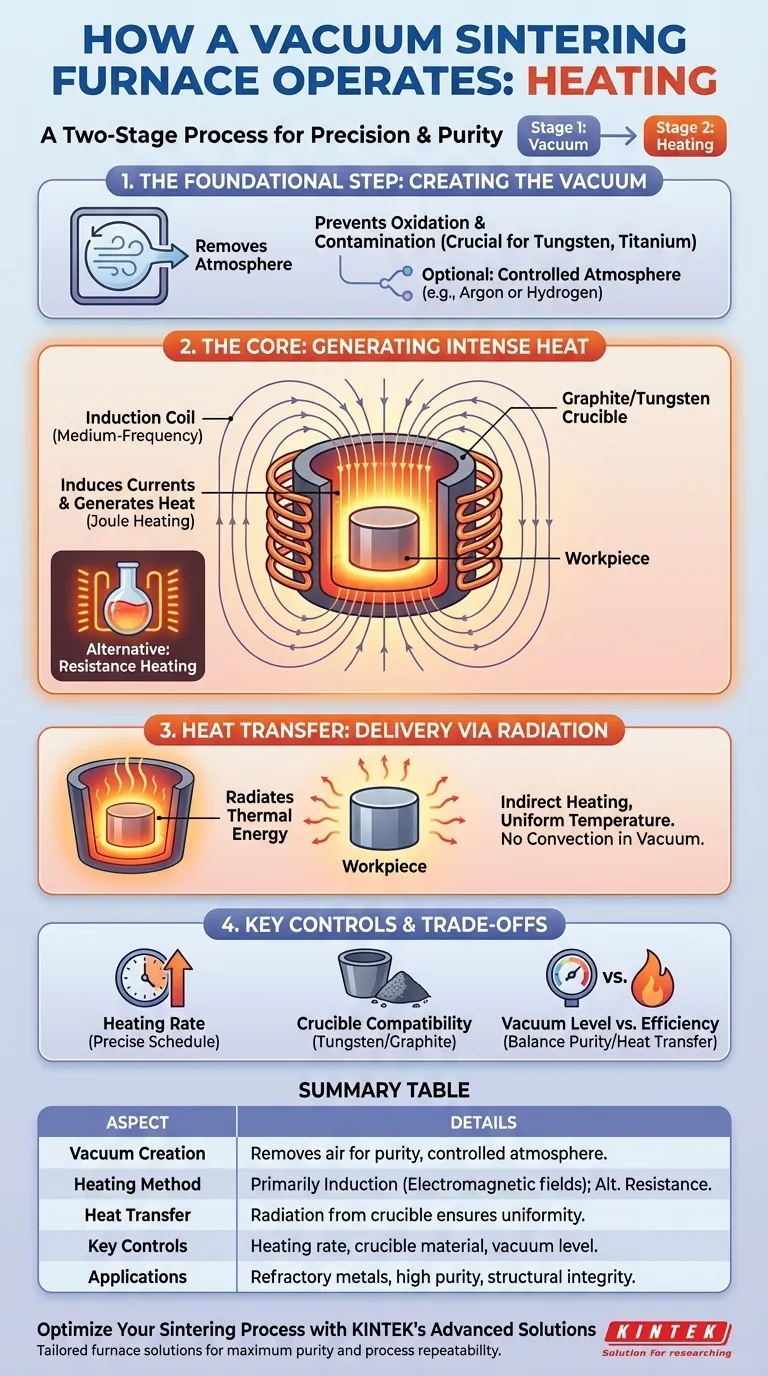

At its core, a vacuum sintering furnace operates by using a two-stage process. First, it removes the atmosphere from a sealed chamber to create a clean, controlled vacuum. Then, it generates intense heat—most commonly through electromagnetic induction—which is radiated onto the material to fuse it into a solid mass without melting it.

The fundamental goal of this heating method is not simply to achieve high temperatures, but to do so with absolute precision in an ultra-pure environment. This prevents unwanted chemical reactions, ensuring the final product has superior structural integrity and purity.

The Foundational Step: Creating the Vacuum

Before any heating occurs, the furnace must establish a stable vacuum. This initial step is non-negotiable and is central to the entire process.

Preventing Oxidation and Contamination

By removing air and other reactive gases, the vacuum environment prevents the material from oxidizing or becoming contaminated at high temperatures. This is critical for processing reactive or refractory metals like tungsten and titanium.

Enabling Precise Atmospheric Control

Once a vacuum is achieved, the furnace operator can introduce a specific, controlled atmosphere if needed. For certain processes, a partial pressure of an inert gas (like argon) or a reactive gas (like hydrogen, for deoxidation) may be used to further refine the sintering environment.

The Core Heating Mechanism: How Heat is Generated

With the vacuum established, the furnace begins the heating cycle. While several methods exist, one is dominant in high-performance applications.

Induction Heating: The Primary Method

Most modern vacuum sintering furnaces use medium-frequency induction heating. An electrical coil outside the hot zone generates a powerful alternating magnetic field.

This field passes through a graphite or tungsten crucible inside the furnace. The crucible resists the magnetic field, which induces powerful electrical currents within it, generating intense heat (Joule heating).

Resistance Heating: An Alternative Approach

An alternative method uses high-power resistance heating elements, often made of graphite, molybdenum, or tungsten. These heaters surround the work area (sometimes called a retort) and generate heat much like a conventional oven, but at far higher temperatures. The heat is then transferred to the workpiece inside.

Heat Transfer: Delivering Energy to the Workpiece

Generating heat is only half the battle. The system must deliver that heat uniformly to the material being sintered.

From Crucible to Component via Radiation

In the vacuum, heat transfer via convection is negligible. Instead, the heated crucible or heating elements radiate thermal energy directly to the workpiece. This indirect heating is key to the process.

Ensuring Uniform Temperature

Because the entire crucible becomes the heat source, it radiates energy from all sides toward the workpiece at its center. This promotes exceptional temperature uniformity, preventing the hot spots and thermal gradients that can compromise a part's structural integrity.

Understanding the Trade-offs and Key Controls

The effectiveness of vacuum sintering heating lies in precise control over multiple variables. Misunderstanding these can lead to poor outcomes.

The Importance of Heating Rate

The rate of temperature increase is as critical as the final sintering temperature. A programmable control system allows the operator to ramp the temperature up and down on a precise schedule, which is essential for managing material stresses and ensuring a complete sintering process.

Material and Crucible Compatibility

The choice of crucible material is deliberate. A tungsten crucible is used for very high-temperature applications involving refractory metals, while a graphite crucible is a common choice for other materials. The crucible must be able to withstand the target temperature without reacting with the workpiece.

Vacuum Level vs. Efficiency

A deeper vacuum ensures higher purity, but it can also make heat transfer less efficient by eliminating all gas molecules that could help conduct heat. The process must balance the required vacuum level for purity against the need for efficient and uniform heating.

Making the Right Choice for Your Sintering Goal

Understanding the principles of vacuum furnace heating allows you to tailor the process to your specific objective.

- If your primary focus is maximum purity for refractory metals: The combination of a deep vacuum and induction heating of a chemically compatible crucible (like tungsten) is the definitive method.

- If your primary focus is process repeatability and uniformity: Your success depends on the synergy between the vacuum system, a precise temperature controller, and an indirect heating method that ensures even thermal radiation.

- If you are troubleshooting inconsistent results: Immediately investigate the stability of your vacuum during the heating cycle, the accuracy of your temperature sensors (thermocouples), and the physical integrity of your heating elements or crucible.

By mastering these principles of vacuum, heat generation, and thermal transfer, you gain complete control over your material's final properties.

Summary Table:

| Aspect | Details |

|---|---|

| Vacuum Creation | Removes air to prevent oxidation and contamination, enabling controlled atmospheres. |

| Heating Method | Primarily induction heating via electromagnetic fields; alternative is resistance heating. |

| Heat Transfer | Radiation from crucible to workpiece ensures uniform temperature without convection. |

| Key Controls | Heating rate, vacuum level, and crucible material compatibility for optimal sintering. |

| Applications | Ideal for refractory metals like tungsten and titanium, ensuring high purity and structural integrity. |

Optimize Your Sintering Process with KINTEK's Advanced Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need maximum purity for refractory metals or enhanced process repeatability, our expertise ensures superior results. Contact us today to discuss how we can tailor a furnace to your specific sintering goals and boost your material performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes