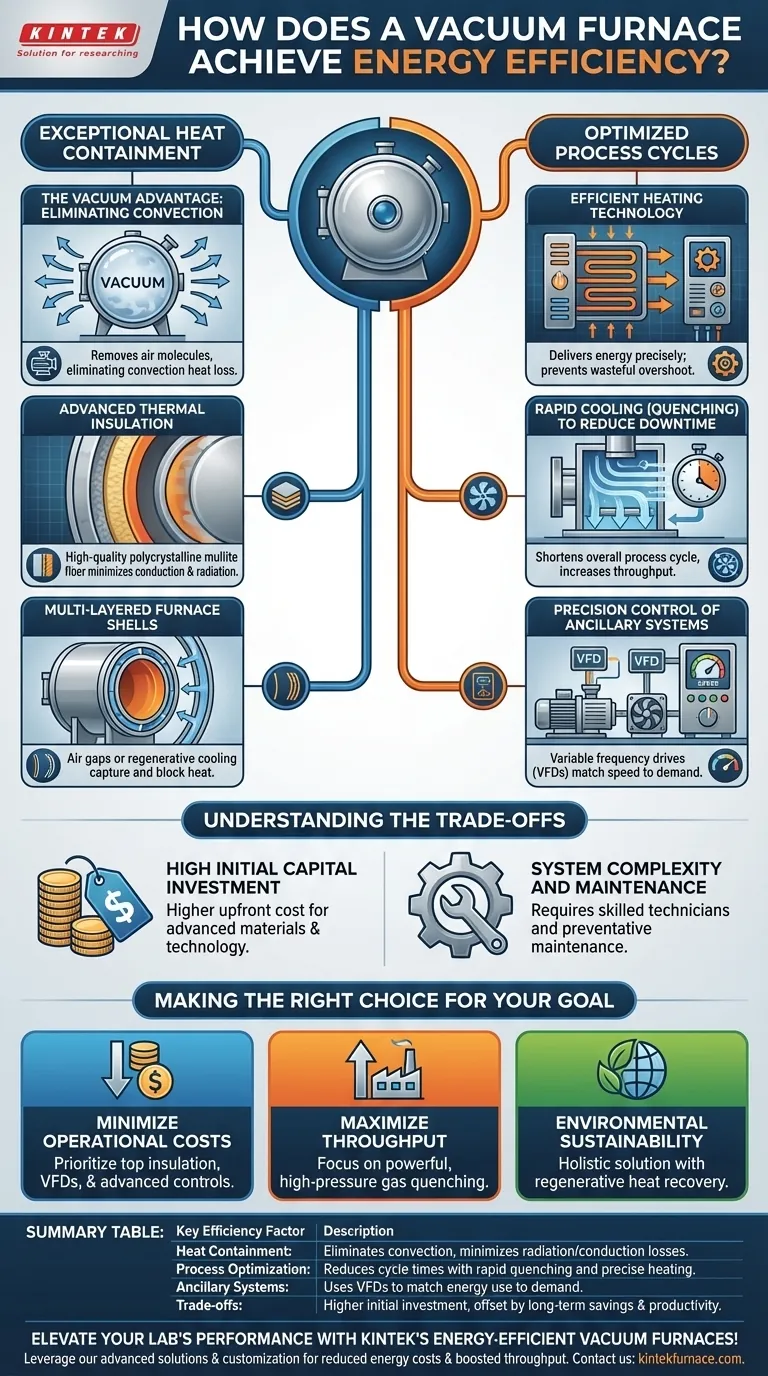

At its core, a vacuum furnace achieves remarkable energy efficiency through a two-pronged strategy: exceptional heat containment and highly optimized process cycle times. By creating a vacuum, it eliminates convective heat loss, while advanced insulation minimizes thermal radiation and conduction, ensuring that energy is used to heat the product, not the surrounding environment.

The true efficiency of a vacuum furnace isn't just about insulation; it's about a complete system design that minimizes energy waste during every phase of operation—from heating and holding to rapid cooling—thereby reducing total cycle time and increasing throughput.

The First Principle: Superior Heat Containment

A furnace's primary job is to get hot and stay hot. A vacuum furnace excels at this by systematically attacking the three modes of heat transfer: convection, conduction, and radiation.

The Vacuum Advantage: Eliminating Convection

The most significant factor is the vacuum itself. By removing most of the air molecules from the heating chamber, you eliminate convection as a major path for heat loss.

Heat simply cannot be carried away by moving air currents if there is no air to move. This immediately makes the furnace far more efficient than a traditional atmosphere furnace.

Advanced Thermal Insulation

To combat conduction and radiation, vacuum furnaces rely on multi-layered, high-performance insulation. This is often made from materials like high-quality polycrystalline mullite fiber.

This advanced insulation enables extremely fast heating rates because very little energy is absorbed by the furnace walls. It also keeps the exterior shell cool, which is a direct indicator that heat is being kept inside the chamber where it belongs.

Multi-Layered Furnace Shells

Modern designs often feature double-layer furnace shells. This creates an air gap between the inner and outer walls, which acts as an additional layer of insulation.

Some systems even incorporate advanced air or water cooling channels within the shell design. These systems not only protect the furnace structure but can also be designed as regenerative systems that capture waste heat for other uses.

The Second Principle: Optimized Process Cycles

Efficiency isn't just about preventing heat from escaping; it's also about using energy effectively and completing the work as quickly as possible.

Efficient Heating Technology

Vacuum furnaces utilize advanced heating elements and power controls that deliver energy precisely where and when it is needed. This prevents the wasteful "overshoot" common in less sophisticated systems.

The result is faster, more uniform heating of the workload, which reduces the total time the furnace must be held at its maximum temperature.

Rapid Cooling (Quenching) to Reduce Downtime

A key efficiency gain comes from the ability to cool the workload rapidly. This process, known as quenching, shortens the overall process cycle time significantly.

By reducing the time between loads, the furnace's productivity increases, meaning more work is done for every kilowatt-hour of energy consumed. A furnace that is cooling is not processing parts, so faster cooling directly translates to higher operational efficiency.

Precision Control of Ancillary Systems

Efficiency extends to the support systems. Vacuum pumps and cooling fans can be major energy consumers.

The use of variable frequency drives (VFDs) allows the system to adjust the speed of these motors to match the exact demand of the process. Instead of running at 100% power continuously, the pumps and fans ramp up and down as needed, drastically cutting their energy consumption.

Understanding the Trade-offs

While highly efficient, this technology requires a clear understanding of its associated costs and complexities.

High Initial Capital Investment

The advanced materials, precision engineering, and sophisticated control systems that deliver this efficiency come at a cost. The initial purchase price of a vacuum furnace is typically higher than that of a conventional atmosphere furnace.

This investment is justified by lower long-term operational costs, including reduced energy bills and higher throughput, but the upfront capital expenditure must be planned for.

System Complexity and Maintenance

A vacuum furnace is a complex machine with multiple integrated systems—vacuum, heating, cooling, and controls. Proper operation and maintenance require skilled technicians.

While robust, troubleshooting can be more involved than with simpler furnace types. Investing in operator training and a preventative maintenance plan is critical to realizing the furnace's long-term efficiency benefits.

Making the Right Choice for Your Goal

The "best" efficiency strategy depends entirely on your operational priorities.

- If your primary focus is minimizing operational costs: Prioritize a furnace with the highest quality insulation, VFDs on all motors, and a state-of-the-art control system to minimize baseline energy use.

- If your primary focus is maximizing throughput: Focus on designs with powerful, high-pressure gas quenching capabilities, as reducing cycle time is the most effective way to lower the energy cost per part.

- If your primary focus is environmental sustainability: Look for a holistic solution that combines all of the above features with a regenerative heat recovery system to minimize both energy consumption and emissions.

Ultimately, a vacuum furnace's efficiency stems from a holistic design philosophy that treats energy as a precious resource at every stage of the process.

Summary Table:

| Key Efficiency Factor | Description |

|---|---|

| Heat Containment | Eliminates convection via vacuum and uses advanced insulation to minimize radiation/conduction losses. |

| Process Optimization | Reduces cycle times with rapid quenching and precise heating controls for higher throughput. |

| Ancillary Systems | Employs variable frequency drives (VFDs) on pumps and fans to match energy use to process demands. |

| Trade-offs | Higher initial investment and complexity, offset by long-term energy savings and increased productivity. |

Elevate your lab's performance with KINTEK's energy-efficient vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, reducing energy costs and boosting throughput. Contact us today to discuss how our tailored high-temperature furnace solutions can drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control