At its core, a porcelain furnace is a high-precision oven that transforms raw dental ceramic materials into strong, life-like dental restorations. It does not make ceramic malleable for in-furnace shaping; rather, it uses a highly controlled cycle of heat and vacuum to sinter—or fuse—layers of porcelain powder that have been meticulously applied by a technician. This process is what creates the final strength, fit, and aesthetic of a crown, veneer, or bridge.

The true function of a porcelain furnace goes beyond simple heating. Its value lies in its ability to execute a precise, programmable firing cycle that controls temperature, time, and atmosphere to transform ceramic powder into a dense, durable, and aesthetically superior restoration.

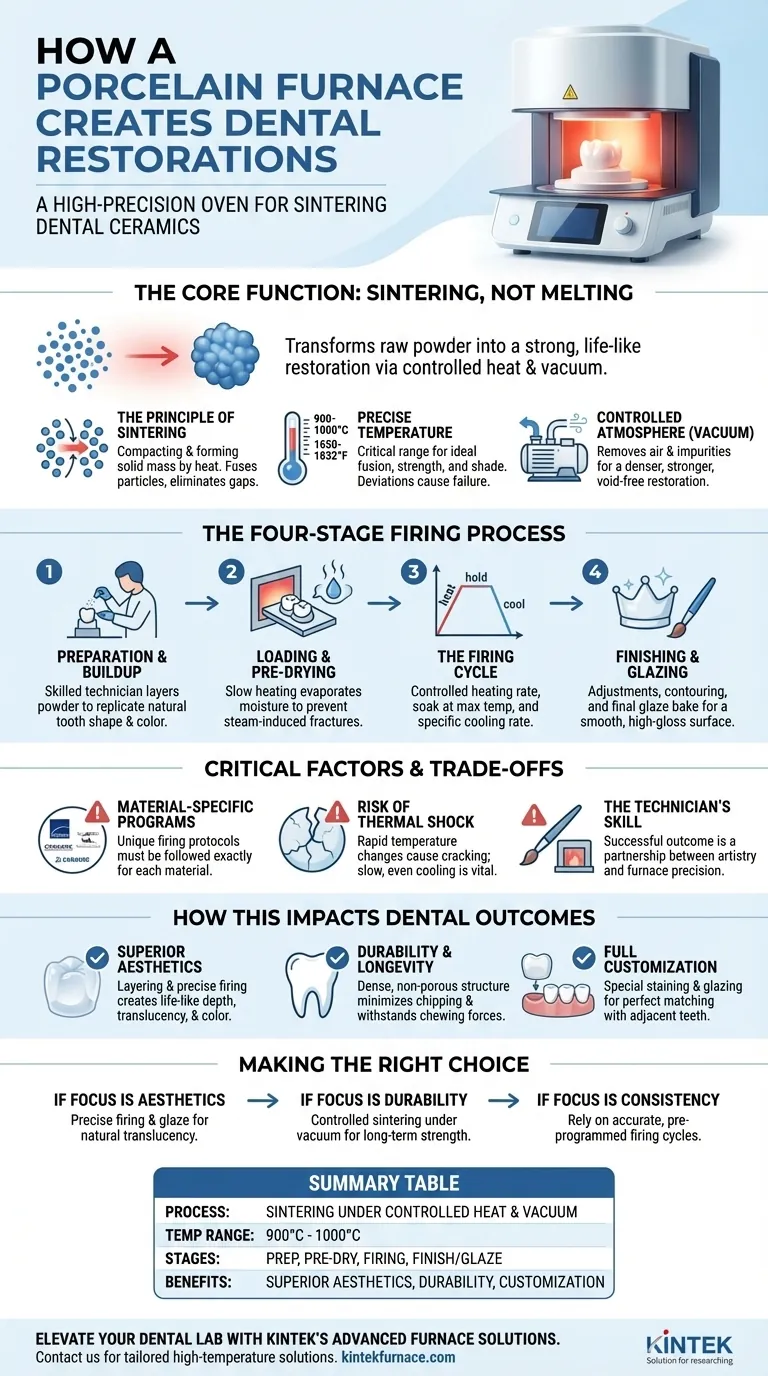

The Core Function: From Powder to Solid Restoration

A porcelain furnace operates on the principle of sintering, not melting. This distinction is critical to understanding how it achieves both strength and beauty in the final product.

The Principle of Sintering

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. Technicians build up the restoration by applying a mixture of porcelain powder and a special liquid onto a substructure or die. The furnace then heats these particles, causing them to fuse together at their contact points, eliminating the gaps between them and creating a single, dense object.

The Role of Precise Temperature

Dental ceramics require firing temperatures typically between 900°C and 1000°C (1650°F and 1832°F). Even a minor deviation from the material-specific temperature can result in a failed restoration. Precise control ensures the porcelain reaches the ideal state of fusion for maximum strength and correct shade, without over-firing, which can cause slumping or a glassy, unnatural appearance.

The Importance of a Controlled Atmosphere

Modern furnaces perform their firing cycles under a vacuum. As the temperature rises, a vacuum pump removes air from the firing chamber. This pulls out impurities and trapped gases from between the porcelain particles, resulting in a significantly denser and stronger restoration free of bubbles or voids.

The Four-Stage Firing Process

Every successful restoration is the result of a carefully executed, multi-stage process. The furnace automates the most critical part of this journey.

Stage 1: Preparation and Buildup

Before the furnace is even turned on, a skilled technician manually builds the restoration. Using fine brushes, they apply layers of porcelain powder to replicate the dentin and enamel of a natural tooth, defining its shape, color, and translucency.

Stage 2: Loading and Pre-Drying

The restoration is placed on a ceramic tray and loaded into the furnace. An initial low-temperature "pre-drying" phase slowly heats the piece to evaporate all moisture from the modeling liquid. Rushing this step can cause steam to build up and fracture the porcelain.

Stage 3: The Firing Cycle

This is the heart of the process, where the furnace's program takes over. The cycle consists of a controlled heating rate, a hold (or "soak") at the maximum temperature, and a specific cooling rate. Each parameter is dictated by the type and thickness of the ceramic being used.

Stage 4: Finishing and Glazing

After the main "dentin" and "enamel" bakes, the restoration is adjusted and contoured. A final, thin layer of glaze is applied, and the piece undergoes a last, quick firing cycle. This glaze bake creates a smooth, high-gloss, and stain-resistant surface that mimics natural tooth enamel.

Understanding the Trade-offs and Critical Factors

While highly automated, porcelain furnaces are not "press-and-play" devices. Achieving perfect results requires understanding the inherent limitations and variables.

Material-Specific Programs

There is no universal firing program. Every ceramic system from different manufacturers has a unique firing protocol that must be followed exactly. Using the wrong program for a given material is a primary cause of restoration failure.

The Risk of Thermal Shock

Porcelain is a glass-like material and is highly susceptible to cracking from rapid temperature changes, a phenomenon known as thermal shock. The furnace's ability to cool the restoration slowly and evenly is just as important as its ability to heat it, preventing internal stresses that compromise long-term durability.

The Technician's Skill

A furnace provides precision and repeatability, but it cannot compensate for poor preparation. The final outcome is a partnership between the technician's artistry in the buildup and the furnace's ability to execute the firing cycle flawlessly.

How This Impacts Dental Outcomes

The precision of a modern porcelain furnace directly translates into tangible clinical benefits for the patient and dentist.

Achieving Superior Aesthetics

Layering different shades of porcelain and controlling their fusion through precise firing cycles is what allows a crown or veneer to have the depth, translucency, and color gradient of a natural tooth.

Ensuring Durability and Longevity

The sintering process under vacuum creates a dense, non-porous ceramic structure. This minimizes the risk of chipping and fracture, leading to a strong bond and a restoration that can withstand the forces of chewing for years.

Enabling Full Customization

The furnace allows for the creation of highly customized restorations. Technicians can perform special staining and glazing bakes to perfectly match the unique characteristics of a patient's adjacent teeth, ensuring the restoration blends in seamlessly.

Making the Right Choice for Your Goal

- If your primary focus is aesthetics: The furnace's ability to precisely fire multiple layers and a final glaze bake is what creates a life-like, naturally translucent appearance.

- If your primary focus is durability: The controlled sintering process, especially under vacuum, creates the dense, void-free ceramic structure necessary for long-term strength.

- If your primary focus is consistency: Rely on furnaces with accurate, pre-programmed firing cycles specific to the ceramic material to achieve reproducible, high-quality results every time.

Ultimately, the porcelain furnace is the instrument that translates a technician's artistry into a functional, durable, and beautiful clinical reality.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Sintering of porcelain powder under controlled heat and vacuum |

| Temperature Range | 900°C to 1000°C (1650°F to 1832°F) |

| Stages | Preparation, Pre-Drying, Firing Cycle, Finishing and Glazing |

| Benefits | Superior aesthetics, durability, and customization for dental restorations |

Elevate Your Dental Lab with KINTEK's Advanced Furnace Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide dental laboratories with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet the precise demands of dental restoration processes. With strong deep customization capabilities, we ensure our furnaces perfectly align with your unique experimental and production needs, delivering consistent, high-quality results for crowns, veneers, and bridges.

Contact us today to discuss how our tailored furnace solutions can enhance your lab's efficiency and outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time