A porcelain furnace is the primary tool for controlling the final esthetic properties of a dental restoration. It achieves this not simply by heating, but through the precise management of temperature, atmosphere, and time. This control allows a skilled technician to transform ceramic powders into a restoration that convincingly mimics the color, translucency, and surface texture of a natural tooth.

The core function of a porcelain furnace is not just to bake ceramic, but to precisely manage the sintering process in a controlled environment. This meticulous control is what directly translates into lifelike esthetics by preventing discoloration, eliminating porosity, and ensuring structural integrity.

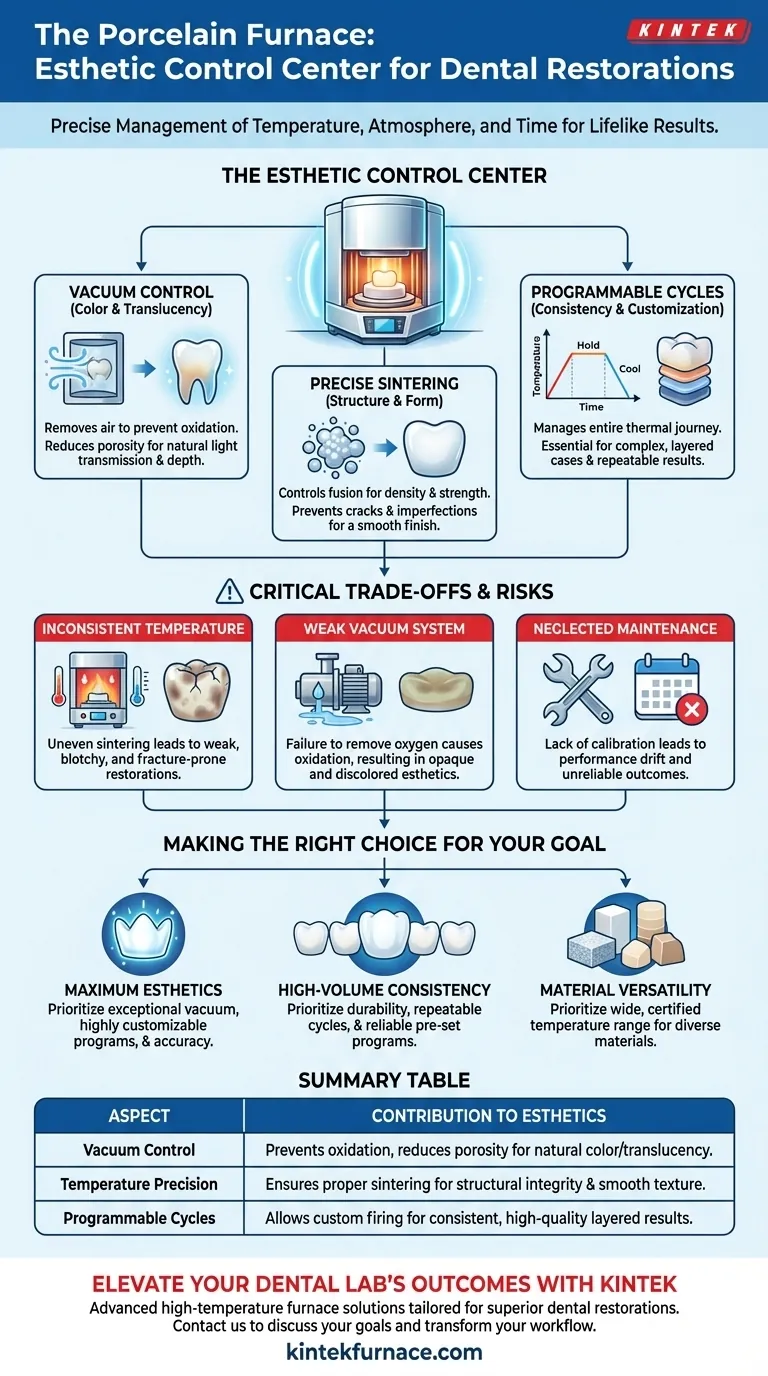

The Furnace as an Esthetic Control Center

A modern porcelain furnace is more than an oven; it is a precision instrument that gives technicians direct control over the variables that create a beautiful and durable restoration. Its contribution goes far beyond simple hardening.

Achieving Lifelike Color and Translucency

The most significant esthetic contribution comes from the furnace's ability to create a controlled vacuum. By removing air from the firing chamber, the vacuum prevents oxygen from reacting with the ceramic materials.

This process, known as firing in a vacuum, is critical. It prevents oxidation that can otherwise dull colors and create a gray or opaque appearance.

Furthermore, the vacuum reduces porosity in the final ceramic. A less porous material allows light to pass through it more naturally, creating the depth and translucency that are the hallmarks of a vital-looking tooth.

Ensuring Structural Integrity and Form

Esthetics are not just about color. The furnace’s precise temperature control is what governs sintering—the process where individual ceramic particles fuse together into a solid, strong mass.

Proper sintering, guided by accurate heating and cooling rates, ensures the restoration is dense and free of internal stresses. This prevents microscopic cracks or surface imperfections that would otherwise scatter light unnaturally and compromise the final polish.

This process locks in the intricate shape and layered anatomy built by the technician, ensuring the final form is exactly as intended.

The Power of Programmable Firing Cycles

Modern furnaces use pre-programmed or custom firing cycles that control not just the peak temperature, but the entire thermal journey. This includes the heating rate, how long the temperature is held (the "hold time"), and the cooling rate.

This programmability is essential for complex cases involving multiple layers of different types of porcelain. Each layer may require a specific firing cycle to mature correctly without disturbing the layers beneath it, allowing for the highest level of custom esthetics.

Reproducible cycles also ensure consistency. A furnace that can perfectly repeat a firing program guarantees that results will be predictable from one case to the next.

Understanding the Critical Trade-offs

While essential, the furnace can also be a point of failure if its capabilities or maintenance are overlooked. The quality of the outcome is directly tied to the quality and calibration of the instrument.

The Impact of Inconsistent Temperature

A lower-quality or poorly maintained furnace can suffer from inaccurate temperature readings or "hot spots" within the muffle. This leads to uneven sintering.

Unevenly sintered porcelain can appear blotchy, have poor strength, and may be prone to cracking. This directly compromises both the esthetics and the long-term durability of the restoration.

The Criticality of the Vacuum System

The vacuum system is arguably the most important component for high-end esthetics. A weak pump or a poor seal in the chamber will fail to remove enough oxygen.

This leads directly to the oxidation and increased porosity mentioned earlier. The result is a restoration that looks flat, opaque, and discolored—no matter how skillfully it was layered.

The Myth of "Set and Forget"

Even the most advanced furnace is a precision tool that requires regular calibration and maintenance. Relying on factory settings without periodic checks can lead to a gradual drift in performance.

Technicians must view the furnace as an active part of the workflow, not a passive appliance. Regular temperature calibration and vacuum system checks are non-negotiable for producing consistent, high-quality esthetic work.

Making the Right Choice for Your Goal

Your clinical or business objectives should guide your focus when evaluating or using a porcelain furnace.

- If your primary focus is maximum esthetics: Prioritize a furnace with an exceptional vacuum system, highly customizable firing programs, and proven temperature accuracy for complex layering.

- If your primary focus is high-volume consistency: Choose a furnace known for its durability, repeatable firing cycles, and a library of reliable pre-set programs for common materials.

- If your primary focus is material versatility: Ensure the furnace has a wide, accurate temperature range and is certified by the manufacturers of the specific dental ceramics you intend to use.

Ultimately, mastering the porcelain furnace is foundational to mastering the art and science of modern dental esthetics.

Summary Table:

| Aspect | Contribution to Esthetics |

|---|---|

| Vacuum Control | Prevents oxidation and reduces porosity for natural color and translucency. |

| Temperature Precision | Ensures proper sintering for structural integrity and smooth surface texture. |

| Programmable Cycles | Allows custom firing for layered porcelains, ensuring consistent, high-quality results. |

Elevate Your Dental Lab's Esthetic Outcomes with KINTEK

Are you striving for superior dental restorations that mimic natural teeth in color, translucency, and durability? KINTEK specializes in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—enhanced by deep customization capabilities to meet your unique experimental and production needs. Whether you focus on maximum esthetics, high-volume consistency, or material versatility, our precision instruments ensure reliable performance and stunning results. Don't let equipment limitations hold you back—contact us today to discuss how KINTEK can support your goals and transform your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures