At their core, modern zirconia sintering furnaces improve dental lab efficiency by drastically reducing process times, increasing throughput, and ensuring consistent, reliable results. They achieve this through a combination of rapid heating cycles, high-capacity chambers that can process many units simultaneously, and intelligent process controls that minimize errors and rework.

The true value of a modern sintering furnace is not just in doing one step faster, but in transforming the entire production workflow. By combining speed with high-volume capacity and digital integration, it creates a more predictable, scalable, and profitable laboratory operation.

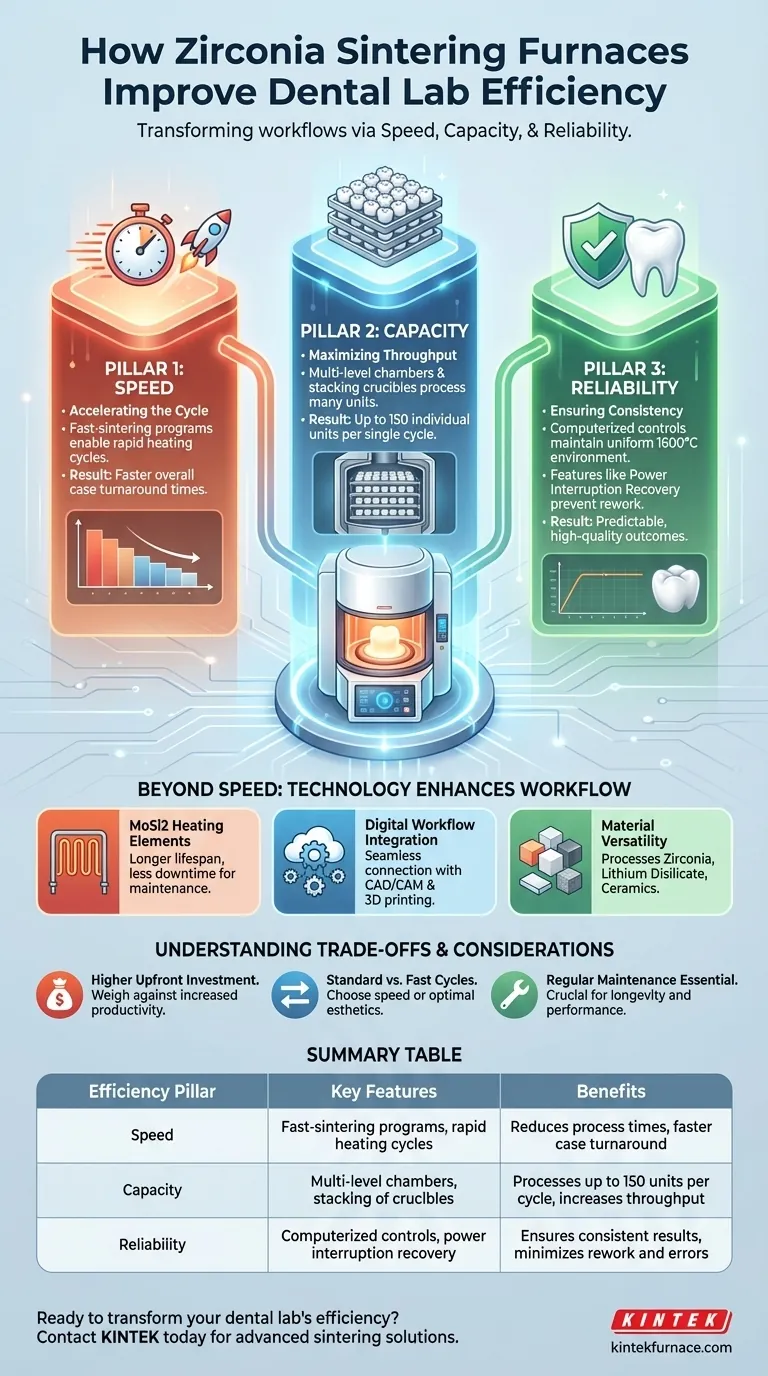

The Three Pillars of Sintering Efficiency

To understand how these furnaces deliver such a significant impact, we must look at the three core areas where they create value: speed, capacity, and reliability.

Pillar 1: Accelerating the Sintering Cycle

Modern furnaces offer specialized, fast-sintering programs that can complete a cycle in a fraction of the time required by older equipment.

This reduction in furnace time directly translates to a faster overall case turnaround time, allowing labs to deliver restorations to clinicians and patients more quickly.

Pillar 2: Maximizing Throughput per Cycle

Efficiency isn't just about speed; it's also about scale. The latest furnaces are designed for high-volume production.

Many models feature multi-level chambers that allow for the stacking of multiple sintering crucibles. This enables a lab to process a large number of restorations—in some cases, up to 150 individual units—in a single cycle. This capacity is critical for labs looking to grow their output without a linear increase in equipment or labor.

Pillar 3: Ensuring Process Reliability and Consistency

Rework is the enemy of efficiency. Modern furnaces are engineered to deliver predictable outcomes every time.

Computerized control systems ensure a perfectly uniform heating environment. This consistency is vital for achieving the full strength, proper shade, and structural integrity of zirconia, which requires precise temperatures that can reach 1600°C.

Furthermore, features like power interruption recovery act as an insurance policy. The furnace can automatically resume its cycle after a power outage, saving an entire batch of restorations from being ruined and protecting hours of work.

Beyond Speed: How Technology Enhances the Workflow

The efficiency gains extend beyond the furnace's primary function. Advanced technology integrates the sintering process more deeply into the modern digital dental workflow.

Advanced Heating Elements (MoSi2)

The most advanced furnaces utilize molybdenum disilicide (MoSi2) heating elements. These components are highly resistant to oxidation and have a significantly longer lifespan than traditional elements.

This leads to less downtime for maintenance and more consistent temperature accuracy over the life of the furnace, ensuring reliable performance year after year.

Digital Workflow Integration

Sintering furnaces are a key component in a fully digital process. They seamlessly connect with CAD/CAM systems.

A technician can leverage 3D printing to create a restoration, which is then sintered to its final, high-strength state. This end-to-end digital workflow dramatically reduces manual effort and production time.

Material Versatility

Many modern furnaces are not limited to zirconia. They are also capable of processing other advanced dental materials like lithium disilicate and various dental ceramics. This versatility allows a lab to expand its service offerings without needing to invest in multiple single-purpose ovens.

Understanding the Trade-offs and Considerations

While highly efficient, these furnaces represent a significant decision for any lab. Objectivity requires acknowledging the associated trade-offs.

Significant Upfront Investment

The advanced technology, precision components, and high-temperature capabilities of these furnaces come with a higher upfront cost compared to older or more basic models. This must be weighed against the expected return on investment from increased productivity.

Standard vs. Fast Cycles

While fast cycles are a key feature, the standard, longer sintering cycles remain necessary for certain zirconia types or to achieve maximum translucency and specific aesthetic results. Labs must understand when to use a fast cycle for speed and when to use a standard cycle for optimal esthetics.

The Necessity of Regular Maintenance

A sintering furnace is a high-performance machine operating under extreme conditions. Regular maintenance is not optional; it is essential to ensure longevity, consistent performance, and the protection of your investment. Neglecting upkeep will compromise results and lead to costly downtime.

Making the Right Choice for Your Lab

Selecting the right sintering furnace depends entirely on your laboratory's specific operational goals.

- If your primary focus is high-volume production: Prioritize models with the largest capacity and ability to stack multiple crucibles to maximize your output per cycle.

- If your primary focus is rapid turnaround: Seek out furnaces with proven and reliable fast-sintering programs to support same-day or next-day restorations.

- If your primary focus is future-proofing and versatility: Choose a furnace with multi-material capabilities and strong digital integration to adapt to evolving technologies and materials.

Ultimately, the right sintering furnace is more than just a piece of equipment; it is a strategic asset that enhances your lab's capacity, predictability, and profitability.

Summary Table:

| Efficiency Pillar | Key Features | Benefits |

|---|---|---|

| Speed | Fast-sintering programs, rapid heating cycles | Reduces process times, faster case turnaround |

| Capacity | Multi-level chambers, stacking of crucibles | Processes up to 150 units per cycle, increases throughput |

| Reliability | Computerized controls, power interruption recovery | Ensures consistent results, minimizes rework and errors |

Ready to transform your dental lab's efficiency with advanced sintering solutions? Contact KINTEK today to learn how our high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, deliver precise customization for your unique needs—boosting productivity, scalability, and profitability through superior R&D and in-house manufacturing.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations