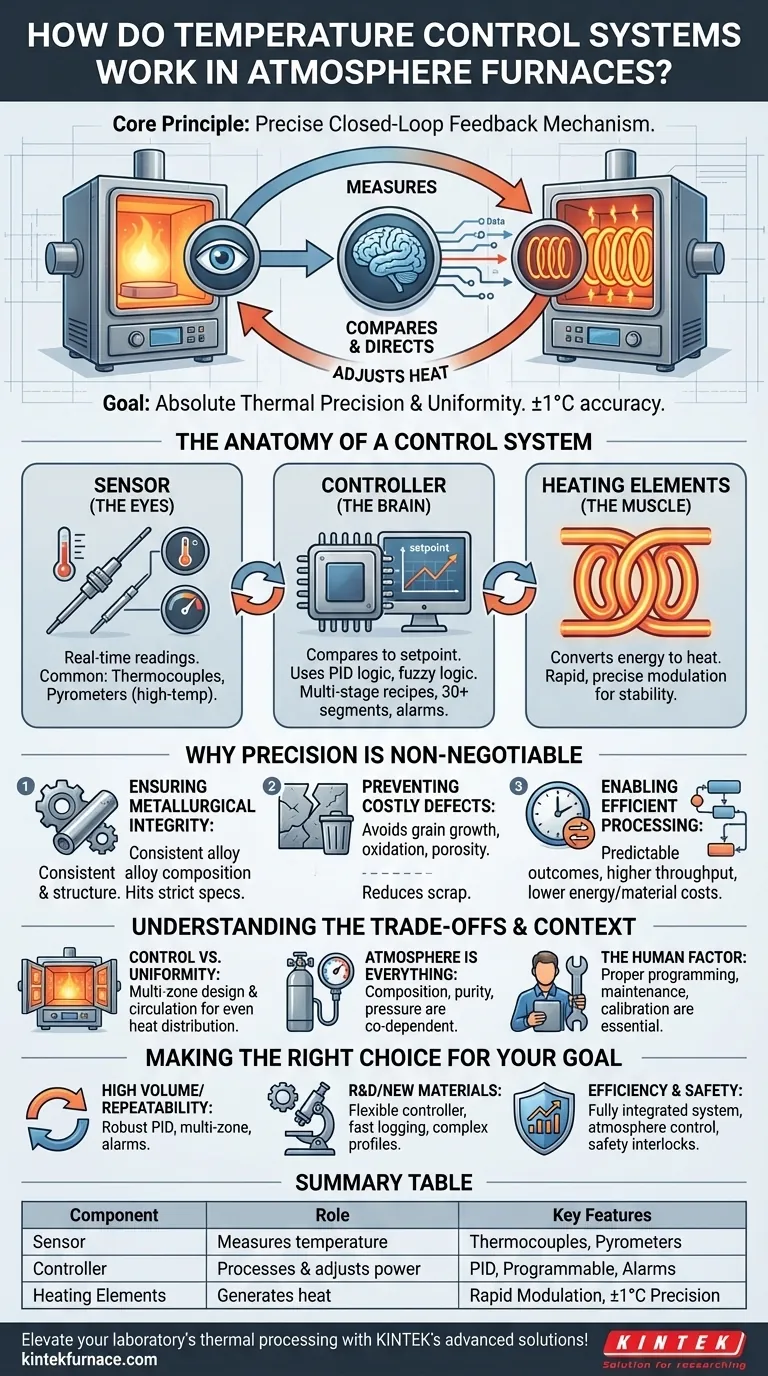

At its core, a temperature control system in an atmosphere furnace operates as a precise, closed-loop feedback mechanism. It continuously measures the internal temperature using sensors, compares that data to a programmed setpoint in a controller, and directs the heating elements to add or reduce energy. This constant cycle of monitoring and adjustment ensures the material being treated receives the exact thermal profile required for its transformation.

The goal of this system is not merely to generate heat, but to achieve absolute thermal precision and uniformity. It is the critical link between the furnace hardware and the final metallurgical properties of your material, where even a deviation of a few degrees can compromise quality and create waste.

The Anatomy of a Control System

A temperature control system is comprised of three essential component types working in concert: the sensors, the controller, and the heating elements. Each plays a distinct role in achieving and maintaining the target temperature.

The Sensor: The Eyes of the Furnace

The system's "eyes" are sensors placed inside the furnace chamber to provide real-time temperature readings.

The most common type is the thermocouple, which measures temperature at a specific point. For processes requiring non-contact measurement or for extremely high temperatures, a pyrometer may be used instead.

The Controller: The Brain of the Operation

The controller is the central processor that makes all the decisions. It takes the temperature reading from the sensor and compares it to the desired temperature, or setpoint.

Modern systems often use a PID (Proportional-Integral-Derivative) controller, sometimes enhanced with fuzzy logic. This unit calculates the difference between the actual and setpoint temperatures and determines the precise amount of power to send to the heating elements.

Advanced controllers allow for highly complex, multi-stage process recipes, with features like 30 or more programmable segments and pre-set heating and cooling curves. They also include critical safety features like over-temperature alarms and automatic shutdown protocols.

The Muscle: The Heating Elements

The heating elements are the components that actually generate the heat. Based on the instructions from the controller, they convert electrical energy into thermal energy.

The controller's ability to rapidly and precisely modulate the power to these elements is what allows the system to react instantly to fluctuations and maintain temperature with extreme accuracy, often within ±1°C of the setpoint.

Why This Precision is Non-Negotiable

Maintaining such tight control is fundamental to the success of any heat treatment process. The consequences of poor control are significant and costly.

Ensuring Metallurgical Integrity

The final mechanical properties of a metal part—its hardness, strength, and ductility—are a direct result of its thermal history. Precise temperature control ensures a consistent alloy composition and structure, producing parts that meet strict engineering specifications every time.

Preventing Costly Defects

Temperature fluctuations can lead to a host of material defects. These include unwanted grain growth, surface oxidation, internal porosity, and distortion. By maintaining stability, the control system prevents defects and dramatically reduces scrap and material waste.

Enabling Efficient Processing

A well-controlled temperature profile enables predictable outcomes, such as efficient mold filling in casting operations. This reliability improves throughput and reduces the energy and material costs associated with failed or out-of-spec batches.

Understanding the Trade-offs and Operational Context

A perfect temperature reading is only one piece of a much larger puzzle. To achieve true process control, you must consider the entire furnace environment.

Control vs. Uniformity

A single thermocouple gives you a precise temperature at one location, but it doesn't guarantee the temperature is the same everywhere else. Temperature uniformity across the entire working volume is critical. This is achieved through proper furnace design, multiple control zones, and effective atmospheric circulation.

Atmosphere is Everything

In an atmosphere furnace, the temperature control system works in tandem with the gas control system. Maintaining the correct atmospheric composition, purity, and pressure is just as important as maintaining the temperature. The two systems are codependent; failure in one negates the success of the other.

The Human Factor

Even the most advanced system is subject to operator error and wear. Proper programming of the controller's thermal profiles is essential. Likewise, regular maintenance and calibration of thermocouples and other equipment are mandatory to ensure the system's readings remain accurate over time.

Making the Right Choice for Your Goal

To ensure success, align the control system's capabilities with your primary operational objective.

- If your primary focus is process repeatability and high volume: Prioritize a robust PID controller with multi-zone control and integrated alarms to ensure every batch is identical.

- If your primary focus is R&D or developing new materials: You need a highly flexible controller with extensive programming segments, fast data logging, and the ability to execute complex thermal profiles.

- If your primary focus is operational efficiency and safety: Invest in a fully integrated system that monitors and controls temperature, atmosphere, and pressure, with comprehensive safety interlocks and shutdown protocols.

Ultimately, mastering the temperature control system is mastering the quality and reliability of your final product.

Summary Table:

| Component | Role | Key Features |

|---|---|---|

| Sensor | Measures temperature | Thermocouples, pyrometers for high accuracy |

| Controller | Processes data and adjusts power | PID logic, programmable segments, safety alarms |

| Heating Elements | Generates heat | Rapid modulation, maintains ±1°C precision |

Elevate your laboratory's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure precise temperature control and uniformity for consistent, high-quality results. Contact us today to discuss how our solutions can optimize your heat treatment processes and reduce waste!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance