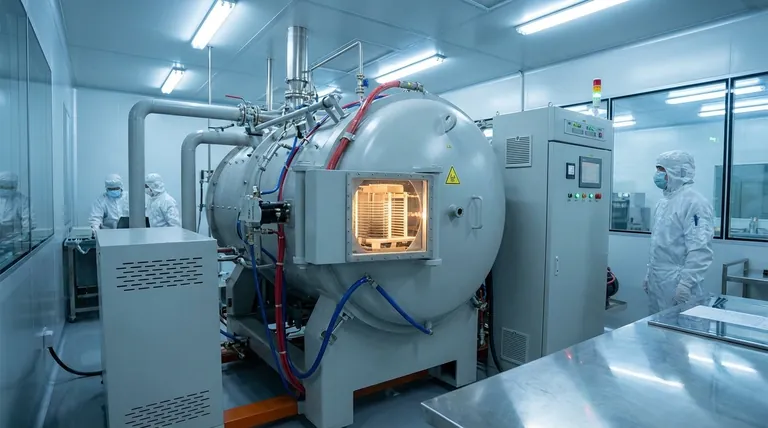

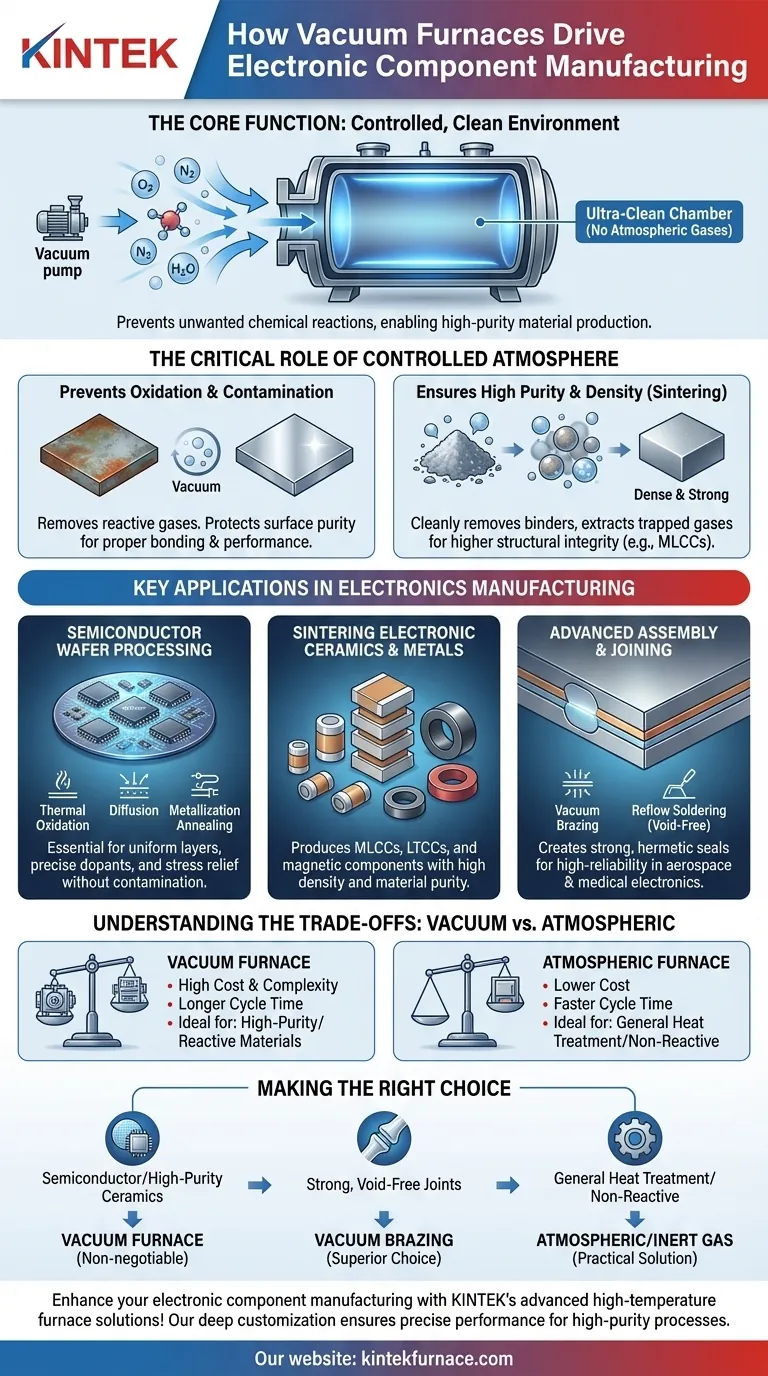

At its core, a vacuum furnace is used in electronic component manufacturing to create an ultra-clean, controlled environment free of atmospheric gases. This prevents unwanted chemical reactions like oxidation, enabling the production of high-purity, high-performance materials and components such as integrated circuits, semiconductor wafers, and specialized electronic ceramics.

The essential function of a vacuum furnace is not merely to provide heat, but to eliminate atmospheric contaminants. This control is the key to achieving the specific material properties and structural integrity demanded by modern, high-precision electronics.

The Critical Role of a Controlled Atmosphere

The primary reason to use a vacuum furnace is to remove reactive gases—namely oxygen, nitrogen, and water vapor. At the high temperatures required for many manufacturing processes, these gases can react with and degrade the materials being processed.

Preventing Oxidation and Contamination

Most electronic materials, especially metals and silicon, will rapidly oxidize when heated in the presence of air. This oxidation can alter electrical properties, inhibit proper bonding, and ultimately cause component failure.

A vacuum furnace evacuates the processing chamber, removing these reactive gases and creating a clean environment. This ensures the material's surface remains pure and its intrinsic properties are preserved.

Ensuring High Purity and Density

Processes like sintering involve heating powdered materials (like ceramics or metals) until their particles fuse together. A vacuum is critical here for two reasons.

First, it cleanly removes binder agents used in the initial forming stage (debinding). Second, it extracts trapped gases from between the powder particles, allowing the material to achieve higher density and structural strength. This is essential for components like Multilayer Ceramic Capacitors (MLCCs).

Key Applications in Electronics Manufacturing

By providing this pristine, high-temperature environment, vacuum furnaces enable several critical manufacturing steps that would otherwise be impossible.

Semiconductor Wafer Processing

In semiconductor fabrication, even microscopic contamination can ruin an entire batch of integrated circuits.

Vacuum furnaces are essential for processes like thermal oxidation, where a perfectly uniform layer of silicon dioxide is grown on a silicon wafer. They are also used for diffusion to introduce dopants precisely and for metallization annealing to relieve stress in thin metal films without causing oxidation.

Sintering Electronic Ceramics and Metals

Many advanced electronic components are made from specialized ceramic or magnetic materials.

Vacuum sintering is used to produce MLCCs, LTCCs (Low-Temperature Co-fired Ceramics), and various magnetic components. The precise control over the atmosphere ensures these parts meet stringent requirements for material purity and performance.

Advanced Assembly and Joining

Joining dissimilar materials is a common challenge in electronics. Vacuum brazing uses a filler metal to create a strong, hermetic seal between components in a vacuum.

This process prevents oxides from forming on the joint surfaces, which would create a weak bond. The result is a clean, strong, and void-free connection, critical for high-reliability applications in aerospace and medical electronics. Similarly, certain high-end reflow soldering processes are performed in a vacuum to eliminate voids in solder joints.

Understanding the Trade-offs: Vacuum vs. Atmospheric Furnaces

While powerful, a vacuum furnace is not always the necessary choice. Understanding its trade-offs compared to simpler atmospheric or "box" furnaces is key.

Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase and operate. The need for robust vacuum pumps, complex sealing mechanisms, and advanced control systems adds to both the initial capital cost and ongoing maintenance.

Cycle Time

Achieving a high vacuum takes time. Furthermore, cooling a workload in a vacuum is slower because convective heat transfer is greatly reduced. This can lead to longer overall process cycles compared to atmospheric furnaces that can use forced gas for cooling.

When a Simpler Furnace is Sufficient

For many general-purpose heat treatments or for processing less reactive materials, a standard atmospheric furnace or a box furnace purged with an inert gas (like nitrogen) is perfectly adequate. These are simpler, faster, and more cost-effective solutions when extreme purity is not the primary requirement.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace hinges entirely on the sensitivity of your materials and the performance requirements of the final component.

- If your primary focus is semiconductor fabrication or high-purity ceramics (MLCCs, LTCCs): A vacuum furnace is non-negotiable to prevent catastrophic contamination and ensure desired material properties.

- If your primary focus is creating strong, void-free joints for high-reliability parts: Vacuum brazing is the superior choice for ensuring maximum joint integrity and cleanliness.

- If your primary focus is general heat treatment or processing non-reactive materials: An atmospheric or inert gas furnace is often the more practical and cost-effective solution.

Ultimately, mastering modern electronics manufacturing requires understanding that the process environment is just as critical as the material itself.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Semiconductor Wafer Processing | Thermal oxidation, diffusion, metallization annealing | Prevents contamination, ensures uniform layers, precise dopant introduction |

| Sintering Electronic Ceramics and Metals | Debinding, sintering for MLCCs, LTCCs | Achieves high density, structural strength, material purity |

| Advanced Assembly and Joining | Vacuum brazing, reflow soldering | Creates strong, hermetic seals, eliminates voids in joints |

Enhance your electronic component manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure precise performance for high-purity processes, helping you achieve superior material properties and reliability. Contact us today to discuss how we can optimize your production and drive innovation in your lab!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering