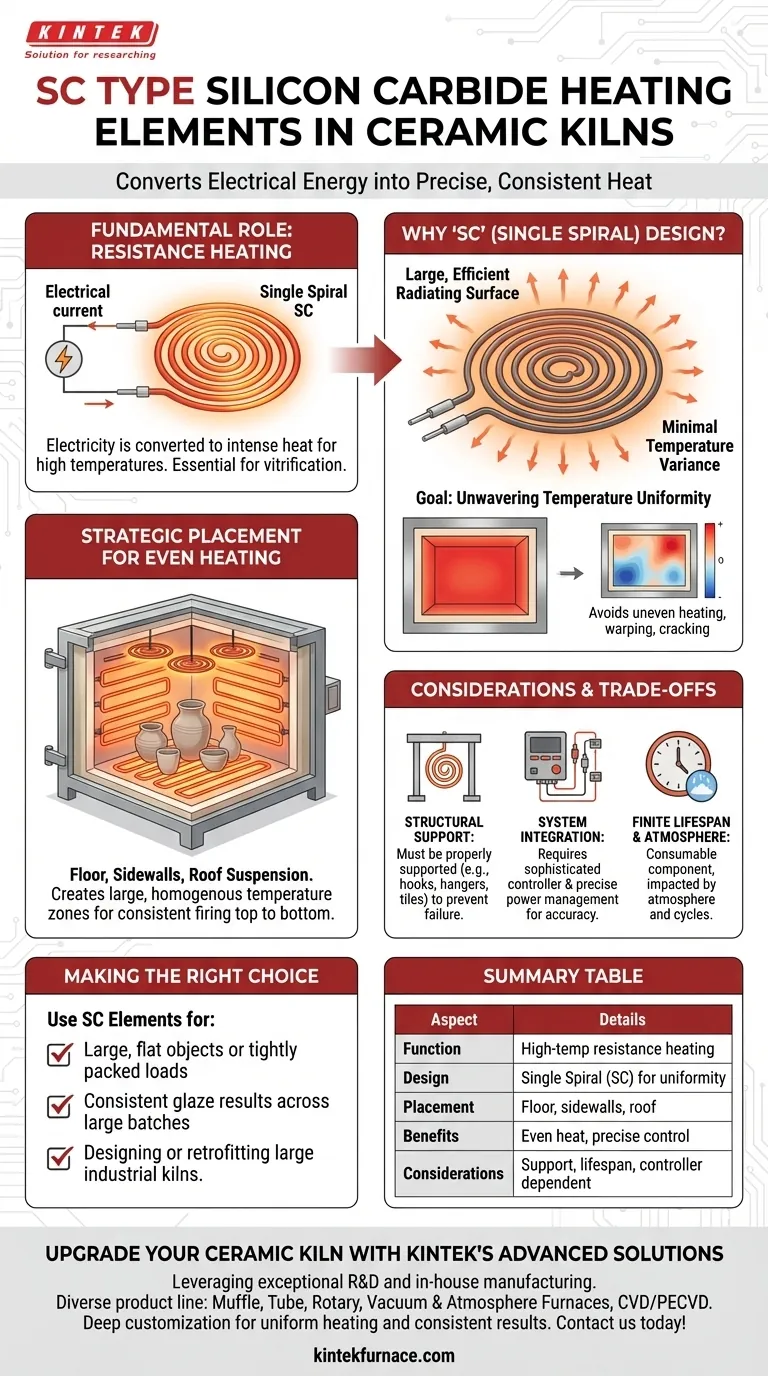

In short, SC Type Silicon Carbide (SiC) heating elements are used in ceramic kilns as high-temperature resistance heaters. They are strategically placed on the floor, sides, or suspended from the roof of the firing chamber to convert electrical energy into consistent, uniform heat, which is essential for successfully firing pottery and ceramics.

The critical factor is the element's design. The "SC" designation refers to a Single Spiral configuration, which is engineered specifically to provide exceptional temperature uniformity over large surface areas, making it ideal for the demands of ceramic firing.

The Fundamental Role of SC Elements in Ceramic Firing

To understand how SC elements are used, we must first understand the problems they solve. The goal of firing ceramics is to apply a precise amount of heat for a specific duration to achieve permanent chemical and physical changes in the clay and glazes.

Converting Electricity into Precise Heat

SC elements function as resistance heaters. When a high electrical current is passed through them, their natural resistance causes them to heat up intensely. This process allows for highly accurate temperature control when managed by a kiln controller.

Achieving High Temperatures for Vitrification

Ceramic processes like vitrification—the transformation of a substance into a glass-like, non-porous state—require extremely high temperatures. The material properties of silicon carbide allow these elements to operate reliably and durably at the temperatures needed to fire ceramics, pottery, and other refractory materials.

Why the 'SC' (Single Spiral) Design Matters for Ceramics

The design of a heating element is not arbitrary; it is directly related to its performance. The Single Spiral configuration of an SC Type element is its defining feature and the primary reason for its use in quality-critical applications.

The Goal: Unwavering Temperature Uniformity

In a ceramic kiln, uneven heating is the enemy. It can cause warping, cracking, dunting (cooling cracks), and inconsistent glaze results. The primary challenge in any kiln is to eliminate hot and cold spots.

How the Single Spiral Achieves Uniformity

The Single Spiral design creates a large, efficient radiating surface. This allows the element to distribute heat broadly and evenly, minimizing temperature variance across the kiln chamber. This is why SC elements are noted for creating small temperature differences.

Ideal Placement for Even Heating

Because of their excellent heat distribution, SC elements are often laid on the furnace floor or mounted along the sidewalls of large box or trolley-style kilns. This bottom-up or side-in heating strategy is highly effective at creating a large, homogenous temperature zone, ensuring that every piece in the load—whether on the top or bottom shelf—is fired correctly.

Understanding the Trade-offs and Considerations

While highly effective, SC elements are a specific tool with their own set of requirements for proper implementation.

Structural Support is Non-Negotiable

These elements are ceramic and must be properly supported. They can be suspended from the roof using specialized hooks, supported by hangers from the sidewalls, or laid into pre-formed ceramic tiles on the kiln floor. Without correct support, they risk mechanical failure.

System Integration

The "high-temperature control accuracy" mentioned for these elements is not inherent to the element alone. It is achieved when the elements are paired with a sophisticated kiln controller and properly configured wiring that can manage the power input precisely.

Finite Lifespan and Atmosphere

Like all heating elements, SC elements have a finite operational life. While durable, their longevity can be impacted by the kiln atmosphere (e.g., oxidation vs. reduction) and the frequency of firing cycles. They are a consumable component that will eventually require replacement.

Making the Right Choice for Your Goal

SC Type elements are a specialized solution for when temperature consistency is paramount. Use this knowledge to guide your decision-making.

- If your primary focus is firing large, flat objects or tightly packed loads: SC elements are an excellent choice for their ability to provide even bottom or side heating, reducing temperature gradients.

- If your primary focus is achieving consistent glaze results across a large batch: The spatial temperature uniformity provided by SC elements helps minimize color and texture variations from shelf to shelf.

- If you are designing or retrofitting a large industrial kiln: Consider using SC elements for floor or side-wall placement to ensure reliable and even heat distribution throughout the entire chamber.

Ultimately, choosing SC Type Silicon Carbide elements is a decision to prioritize temperature uniformity to achieve consistent, high-quality results in your ceramic work.

Summary Table:

| Aspect | Details |

|---|---|

| Function | High-temperature resistance heaters converting electricity to heat |

| Design | Single Spiral (SC) configuration for superior temperature uniformity |

| Placement | Floor, sidewalls, or suspended from roof in kiln chamber |

| Benefits | Even heat distribution, high-temperature operation, precise control |

| Considerations | Requires structural support, finite lifespan, dependent on kiln controller |

Upgrade your ceramic kiln with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for uniform heating and consistent results. Contact us today to discuss how our tailored solutions can enhance your firing processes and boost efficiency!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer