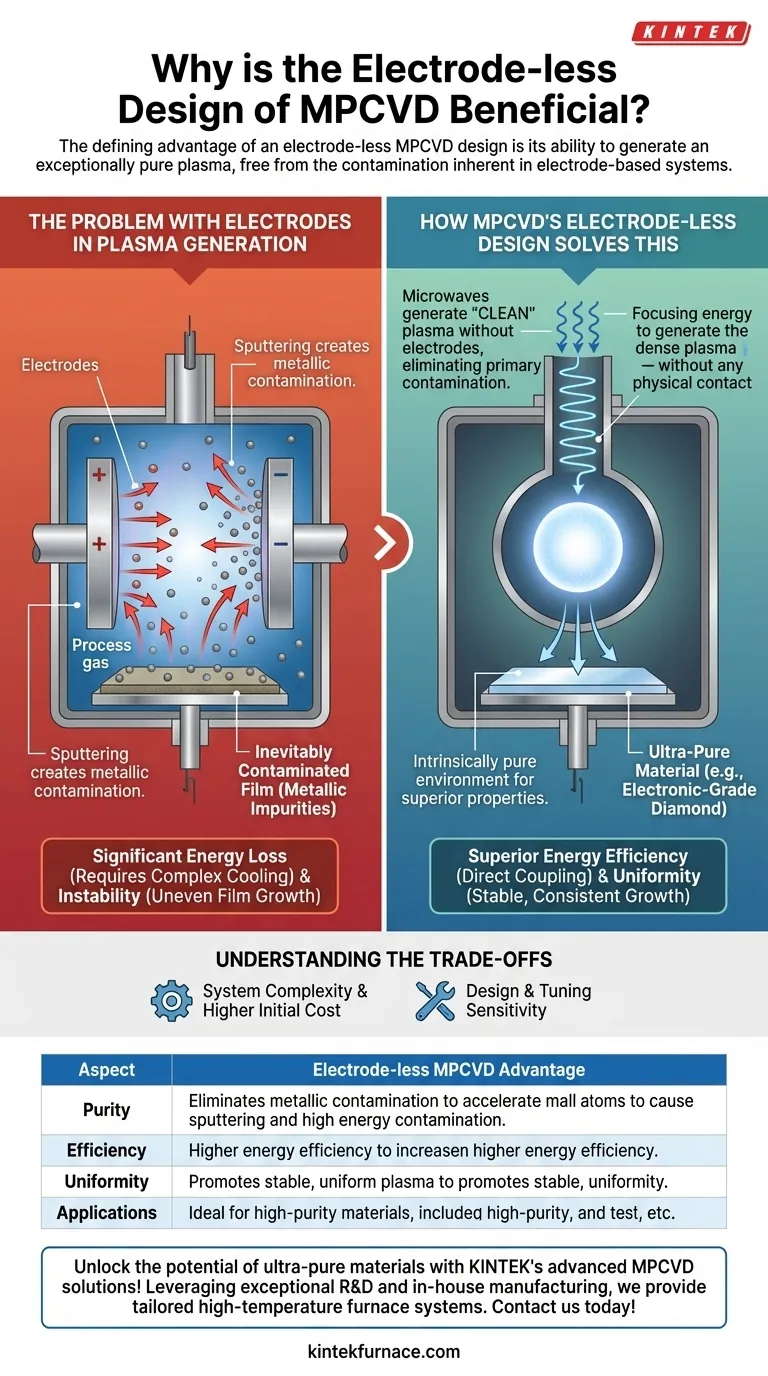

The defining advantage of an electrode-less MPCVD design is its ability to generate an exceptionally pure plasma, free from the contamination inherent in electrode-based systems. By removing the electrodes, you eliminate the primary source of metallic impurities that can degrade the quality of the deposited film, while also significantly improving the system's energy efficiency.

The core problem with traditional plasma systems is that the electrodes required to create the plasma are also a source of contamination. MPCVD's electrode-less approach uses microwaves to generate a "clean" plasma, fundamentally solving this issue and enabling the growth of ultra-pure materials like high-quality diamond.

The Problem with Electrodes in Plasma Generation

To understand the benefit of removing electrodes, we must first understand the problems they create in conventional plasma deposition systems.

How Traditional Plasma is Created

In many plasma systems, such as those using Direct Current (DC) or Capacitively Coupled Plasma (CCP), a strong electric field is applied between two metallic electrodes inside the reaction chamber. This field energizes the process gas, stripping electrons from atoms and creating the plasma.

The Inevitable Contamination Source

The plasma, however, is not a gentle environment. High-energy ions within the plasma are accelerated toward the electrodes and bombard their surfaces. This process, known as sputtering, physically knocks atoms off the electrode material.

These sputtered metallic atoms then mix with the process gas and become incorporated into the growing film as impurities. For applications requiring extreme purity, like electronic-grade diamond, this contamination is unacceptable.

The Issue of Energy Loss and Instability

Electrodes also act as a point of significant energy loss, often requiring complex cooling systems. This reduces the overall energy efficiency of the plasma generation. Furthermore, plasma can concentrate unevenly around electrodes, leading to instability and non-uniform film growth.

How MPCVD's Electrode-less Design Solves This

Microwave Plasma Chemical Vapor Deposition (MPCVD) takes a fundamentally different approach to generating plasma, circumventing the issues caused by electrodes.

Generating Plasma with Microwaves

In an MPCVD system, there are no electrodes inside the vacuum chamber. Instead, microwaves (typically at 2.45 GHz) are generated externally and guided into a precisely engineered resonant cavity.

This microwave energy is focused into the center of the chamber, where it directly couples with the process gas. The microwaves excite the gas molecules, creating a dense, stable, and free-floating plasma ball without any physical contact.

The "Clean" Plasma Advantage

Because there are no internal components for the plasma to sputter, the plasma's composition is determined solely by the precursor gases you introduce. This eliminates the primary pathway for metallic contamination.

The result is an intrinsically pure processing environment, which is essential for depositing high-quality diamond films with superior thermal, optical, and electronic properties.

Superior Energy Efficiency and Uniformity

Coupling microwave energy directly into the gas is a more efficient method of plasma generation than relying on electrical discharge between electrodes. This leads to higher plasma densities at lower power.

The free-floating nature of the plasma ball also promotes a more stable and uniform temperature and chemical environment, which translates to more consistent and repeatable film growth across the substrate.

Understanding the Trade-offs

While highly beneficial, the electrode-less design is not without its considerations. A trusted advisor must acknowledge the complete picture.

System Complexity and Cost

MPCVD reactors, with their microwave generators, waveguides, and resonant cavities, are generally more complex and carry a higher initial cost than simpler DC plasma systems.

Design and Tuning Sensitivity

The performance of an MPCVD system is highly dependent on the geometry of the resonant cavity. Proper design and tuning are critical to achieving a stable plasma discharge at the desired location, which requires significant engineering expertise.

Plasma Initiation

Under certain pressure and gas conditions, initiating the plasma with microwaves can be more challenging than striking an arc between two electrodes. This often requires a "seed" mechanism to begin the process.

Making the Right Choice for Your Application

The decision to use an electrode-less system ultimately depends on the required quality of your final material.

- If your primary focus is producing the highest-purity material (e.g., electronic-grade diamond, optical components): The contamination prevention offered by an electrode-less MPCVD design is non-negotiable.

- If your primary focus is depositing less-sensitive coatings or conducting exploratory, cost-constrained research: An electrode-based system might be a sufficient starting point, but you must be prepared to accept its inherent limitations on film purity.

Ultimately, choosing an electrode-less design is a strategic decision to prioritize material purity and process control above all else.

Summary Table:

| Aspect | Electrode-less MPCVD Advantage |

|---|---|

| Purity | Eliminates metallic contamination from sputtering, enabling ultra-pure films |

| Efficiency | Higher energy efficiency with direct microwave coupling, reducing power loss |

| Uniformity | Promotes stable, uniform plasma for consistent film growth |

| Applications | Ideal for high-purity materials like electronic-grade diamond and optical components |

Unlock the potential of ultra-pure materials with KINTEK's advanced MPCVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including CVD/PECVD setups. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior results. Contact us today to discuss how our electrode-less MPCVD technology can elevate your research and development!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- What role does gas flow rate play in MPCVD? Mastering Deposition Rate and Film Uniformity

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics