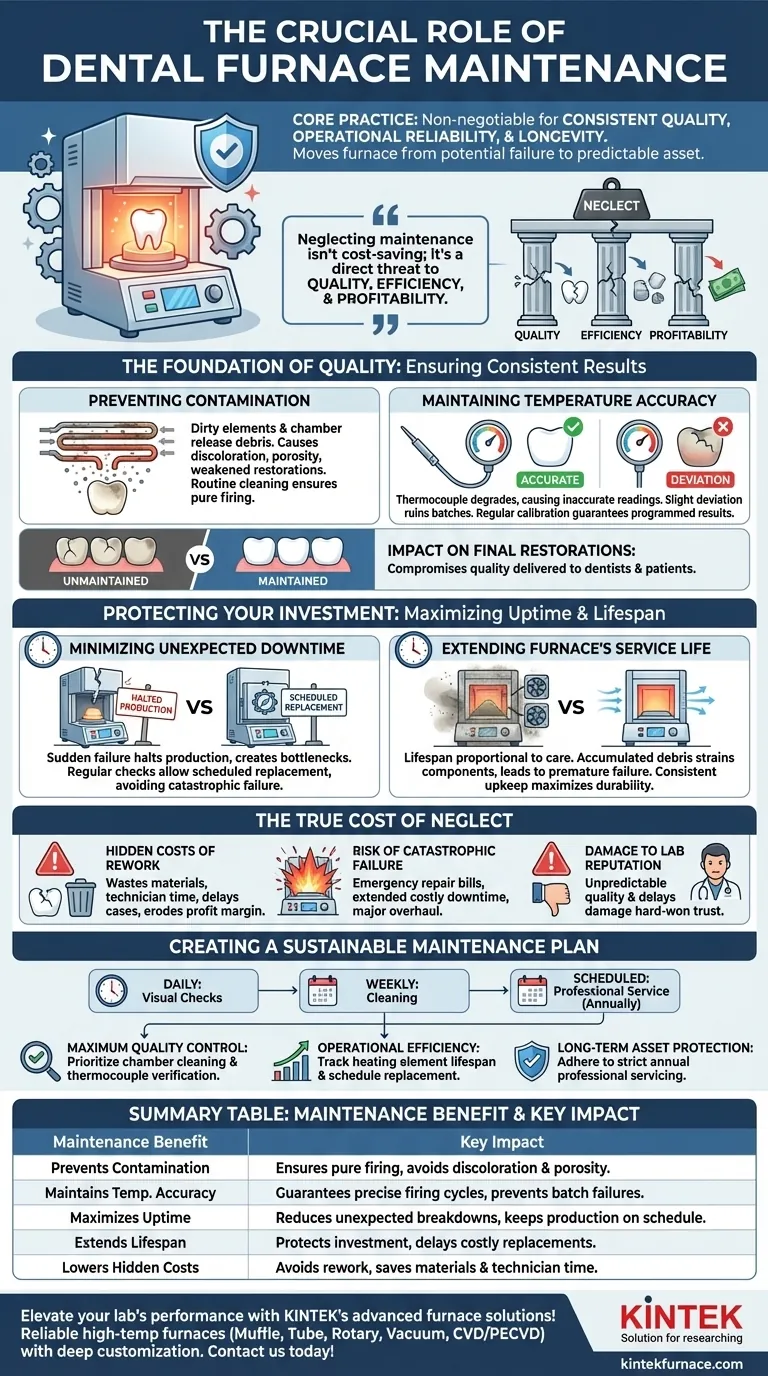

At its core, regular maintenance for a dental lab furnace is a non-negotiable practice for ensuring consistent quality, operational reliability, and the longevity of your investment. It moves the furnace from a potential point of failure to a predictable and stable asset, directly impacting your lab's output and reputation.

Neglecting furnace maintenance isn't a cost-saving measure; it's a direct threat to the three pillars of a successful dental lab: the quality of your restorations, the efficiency of your workflow, and the profitability of your business.

The Foundation of Quality: Ensuring Consistent Results

A furnace is not just a heater; it is a precision instrument. Its primary function is to execute firing cycles with absolute accuracy, and maintenance is what guarantees that precision.

Preventing Contamination

Dirty or corroded heating elements and a contaminated firing chamber can release microscopic debris during the sintering process. This contamination can lead to discoloration, porosity, and a weakened final restoration.

Routine cleaning is the only way to ensure a pure firing environment for materials like zirconia, preventing costly and reputation-damaging remakes.

Maintaining Temperature Accuracy

The thermocouple is the furnace's nerve center, responsible for measuring and reporting temperature. Over time, it can degrade and provide inaccurate readings.

Even a slight temperature deviation can ruin a batch of crowns, affecting their translucency, fit, and structural integrity. Regular checks and calibration ensure what you program is what you get.

The Impact on Final Restorations

Every restoration that leaves your lab is a testament to your commitment to quality. An unmaintained furnace introduces unacceptable variables that compromise the final product delivered to dentists and their patients.

Protecting Your Investment: Maximizing Uptime and Lifespan

A dental furnace is a significant capital expense. Proactive maintenance is the most effective strategy for protecting its value and ensuring it remains a productive asset for as long as possible.

Minimizing Unexpected Downtime

Sudden equipment failure is one of the most disruptive events in a dental lab. It halts production, creates bottlenecks, and can lead to missed deadlines.

Regular maintenance helps identify signs of wear and tear on critical components like heating elements and relays, allowing for scheduled replacement during off-hours instead of a catastrophic failure during a critical firing cycle.

Extending the Furnace's Service Life

Just like any high-performance machine, a furnace's lifespan is directly proportional to its care. Accumulated dust and debris can strain cooling fans and electronics, while corroded components work less efficiently, leading to premature failure.

Consistent upkeep, including professional servicing at least once a year, maximizes the durability and service reliability of the unit.

The True Cost of Neglect

Choosing to defer maintenance introduces significant risks and hidden costs that far outweigh the expense of routine service.

The Hidden Costs of Rework

A single failed sintering cycle due to a faulty component doesn't just waste materials. It wastes technician time, delays cases, and erodes your profit margin on every affected job.

The Risk of Catastrophic Failure

Ignoring early warning signs can lead to a complete system failure, resulting in emergency repair bills and extended, costly downtime. What could have been a simple component swap becomes a major overhaul.

The Damage to Lab Reputation

Consistently delivering high-quality restorations on time builds trust with your dental clients. Unpredictable quality or delays caused by equipment failure can quickly damage a hard-won reputation.

Creating a Sustainable Maintenance Plan

A simple, documented plan transforms maintenance from a chore into a strategic advantage. It should include daily visual checks, weekly cleaning, and scheduled professional service.

- If your primary focus is maximum quality control: Prioritize routine cleaning of the firing chamber and regular verification of temperature accuracy with your thermocouple.

- If your primary focus is operational efficiency: Emphasize tracking the lifespan of heating elements and scheduling their replacement to prevent unexpected downtime.

- If your primary focus is long-term asset protection: Adhere strictly to an annual professional servicing schedule to ensure all internal components and safety systems are functioning correctly.

Ultimately, disciplined maintenance ensures your furnace remains a reliable partner in producing excellence.

Summary Table:

| Maintenance Benefit | Key Impact |

|---|---|

| Prevents Contamination | Ensures pure firing, avoids discoloration and porosity in restorations |

| Maintains Temperature Accuracy | Guarantees precise firing cycles, prevents batch failures |

| Maximizes Uptime | Reduces unexpected breakdowns, keeps production on schedule |

| Extends Lifespan | Protects investment, delays costly replacements |

| Lowers Hidden Costs | Avoids rework, saves materials and technician time |

Elevate your dental lab's performance with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing quality and efficiency. Don't let equipment issues hold you back—contact us today to discuss how our tailored solutions can drive your success!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique