Positive pressure is the single most critical safety and quality control parameter in atmosphere furnace operation. In essence, it is a proactive safety measure that ensures any leak in the furnace system flows outward, not inward. By maintaining a pressure inside the furnace that is slightly higher than the surrounding ambient air, you prevent oxygen from entering and mixing with the combustible process gases, which would create a severe explosion risk and compromise the metallurgical integrity of the workpieces.

An atmosphere furnace is designed to be a sealed system. Maintaining a slight positive pressure ensures that any leaks flow out of the furnace, not in, thereby guaranteeing both the safety of the operation and the integrity of the controlled atmosphere.

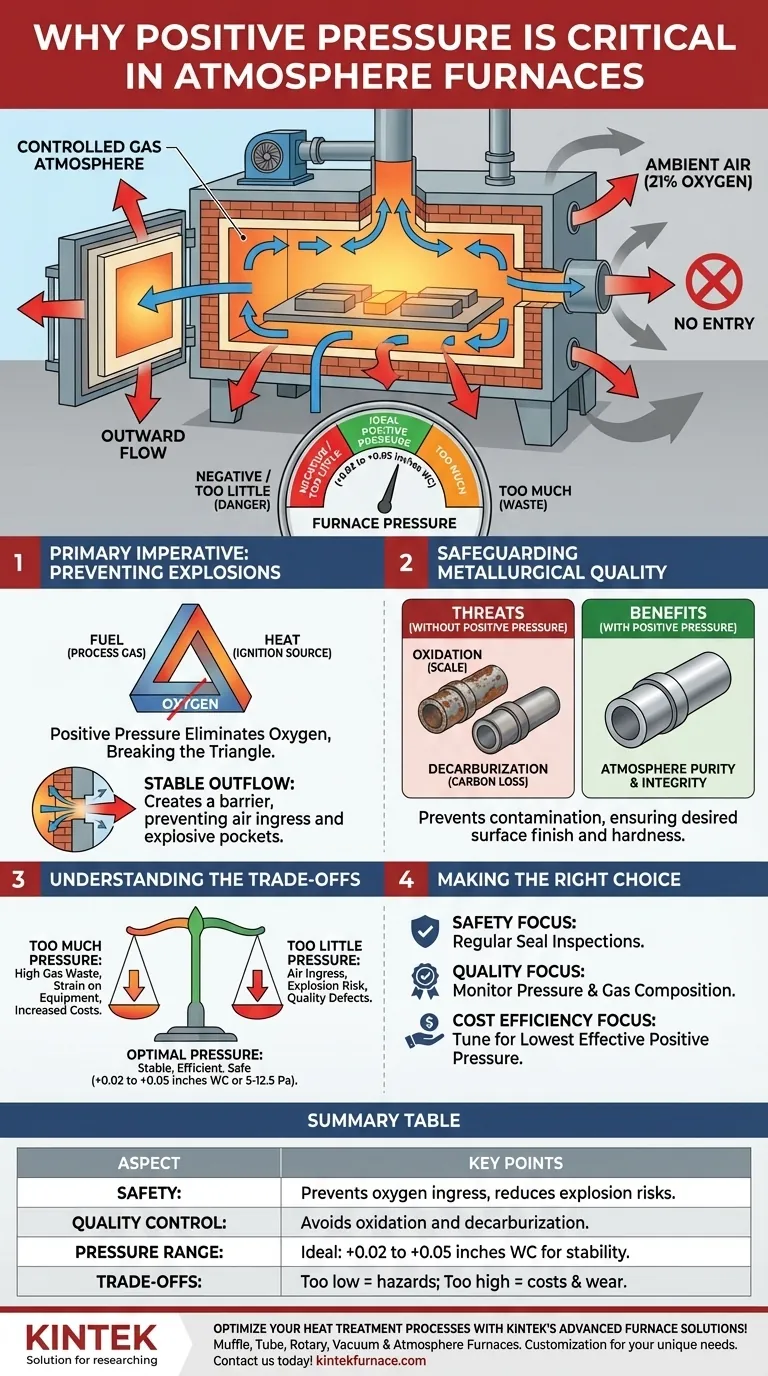

The Primary Imperative: Preventing Explosions

The most crucial reason for maintaining positive pressure is to mitigate the risk of a furnace explosion. This is a fundamental principle of industrial heating safety.

The Fire Triangle in a Furnace Context

For an explosion to occur, three elements are required: fuel, oxygen, and an ignition source. In an atmosphere furnace, you have two of these by design: the flammable process gas (the fuel) and high temperatures (the ignition source).

Positive pressure is the engineering control that reliably eliminates the third element: oxygen.

How Leaks Become Hazards

Furnaces have numerous potential leak points: door seals, fan shafts, thermocouple ports, and brickwork joints. If the internal pressure were neutral or negative, any of these points would act as a vacuum, pulling outside air into the hot zone.

This influx of air (approximately 21% oxygen) can create localized pockets of explosive mixtures. When these pockets encounter the furnace's inherent heat, a deflagration or explosion can occur.

The Role of Stable Outflow

By ensuring a slight, constant positive pressure, you create a gentle, continuous outflow of atmosphere gas from these same leak points. This outflow acts as a barrier, physically preventing air from ever entering the chamber.

Safeguarding Metallurgical Quality

Beyond safety, positive pressure is essential for maintaining the specific, controlled atmosphere required for high-quality heat treatment. Air intrusion is a form of contamination that ruins the process.

The Threat of Oxidation

Oxygen from the air will readily react with the hot surface of steel parts. This reaction forms an undesirable layer of iron oxide, commonly known as scale.

This scale can ruin the surface finish, interfere with dimensional tolerances, and create problems for post-treatment processes like plating or coating.

Preventing Unwanted Decarburization

Even small amounts of oxygen and the water vapor present in air can react with the carbon in the surface of steel. This process, called decarburization, removes carbon from the steel, leaving a soft outer layer.

For processes like carburizing or neutral hardening, where a hard, high-carbon surface is the entire goal, decarburization is a critical failure that renders the parts useless.

Ensuring Atmosphere Purity

Manufacturers spend significant resources to generate and supply precise gas mixtures (e.g., endothermic gas, nitrogen-methanol blends). Positive pressure ensures this carefully crafted atmosphere remains pure and performs its intended metallurgical function without contamination.

Understanding the Trade-offs: Finding the Optimal Pressure

Pressure control is not about maximizing pressure; it is about maintaining a stable and specific target. Both excessive and insufficient pressure create problems.

The Problem with Too Much Pressure

An unnecessarily high positive pressure is wasteful and inefficient. It forces a large volume of expensive process gas out of the furnace, dramatically increasing operational costs.

Extremely high pressure can also put undue strain on furnace doors, seals, and refractory structures, potentially accelerating wear and tear.

The Danger of Too Little Pressure

Operating with insufficient positive pressure (or worse, a negative pressure) is the most dangerous condition. It reintroduces the risk of air ingress, leading directly to the safety hazards and quality defects discussed above. Fluctuations near zero pressure are highly unstable and must be avoided.

The Ideal Pressure Range

The industry standard target is a slight but consistent positive pressure. This is typically measured in inches of water column (WC) or Pascals (Pa).

A common target range is +0.02 to +0.05 inches WC (approximately 5 to 12.5 Pa). This is enough to ensure a steady outflow but low enough to minimize gas waste.

Making the Right Choice for Your Operation

Achieving stable furnace pressure requires a holistic approach that combines proper system design, diligent monitoring, and regular maintenance.

- If your primary focus is safety: Regularly inspect and maintain all furnace seals, gaskets, and potential leak points to ensure the positive pressure you establish is effective.

- If your primary focus is product quality: Continuously monitor furnace pressure alongside gas composition (e.g., dew point, carbon potential) to correlate pressure deviations with atmospheric changes.

- If your primary focus is cost efficiency: Tune your pressure control system to maintain the lowest effective positive pressure, preventing both air ingress and excessive gas consumption.

Ultimately, mastering furnace pressure is not just a procedural step; it is the foundation of safe, consistent, and profitable heat treatment.

Summary Table:

| Aspect | Key Points |

|---|---|

| Safety | Prevents oxygen ingress, reducing explosion risks by maintaining outward gas flow. |

| Quality Control | Avoids oxidation and decarburization, ensuring part integrity and surface finish. |

| Pressure Range | Ideal: +0.02 to +0.05 inches WC (5-12.5 Pa) for stability and efficiency. |

| Trade-offs | Too low: safety hazards; too high: increased costs and wear. |

Optimize your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing safety, quality, and cost-efficiency. Contact us today to discuss how we can support your operations!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality