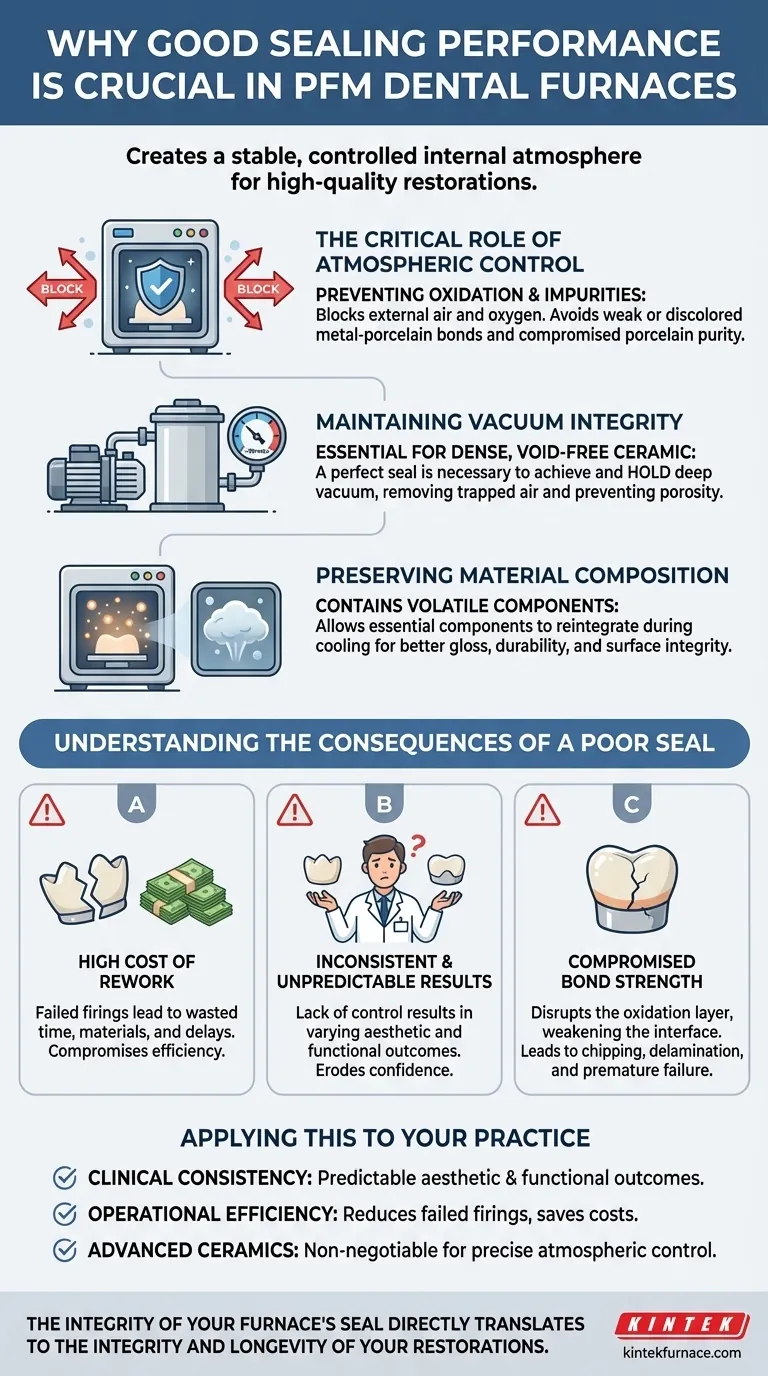

Excellent sealing performance is a foundational requirement in a porcelain-fused-to-metal (PFM) dental furnace because it creates a stable, controlled internal atmosphere. This prevents external air from contaminating the process, controls critical chemical reactions, and stops volatile materials from escaping, directly ensuring the final restoration's quality, strength, and aesthetic integrity.

The seal on a dental furnace is not merely a physical barrier; it is the primary mechanism that guarantees the chemical and physical environment required for successful sintering. A compromised seal invalidates every other setting, leading to unpredictable results and substandard dental restorations.

The Critical Role of Atmospheric Control

A dental furnace does more than just generate heat; it must meticulously manage the atmosphere in which the restoration is fired. The quality of the seal is what makes this management possible.

Preventing Oxidation and Impurities

During the high-temperature sintering cycle, materials are highly reactive. A poor seal allows oxygen and other impurities from the ambient air to enter the firing chamber.

This uncontrolled influx of oxygen can cause excessive oxidation of the metal substructure in PFM crowns, leading to a weak or discolored metal-porcelain bond. It also compromises the purity of the porcelain itself, affecting its final shade and translucency.

Maintaining Vacuum Integrity

Modern furnaces utilize a vacuum pump to remove air from the chamber before and during firing, with some reaching a maximum vacuum of -980 mBar. This process is essential for creating dense, void-free ceramic.

A perfect seal is necessary to achieve and hold this deep vacuum. Any leak will prevent the complete removal of trapped air, resulting in porosity within the porcelain. This porosity is a critical structural weakness, making the restoration prone to fracture.

Preserving Material Composition

High-grade dental porcelains contain specific volatile components that contribute to their final properties, such as gloss and wear resistance.

At sintering temperatures, these components can turn into vapor. A tightly sealed chamber contains these vapors, allowing them to reintegrate into the porcelain during the cooling phase. A leaky furnace allows these essential components to escape, resulting in a dull, less durable final surface.

Understanding the Consequences of a Poor Seal

Investing in a furnace with a superior seal is a matter of risk management. The consequences of an inadequate seal are not just inconvenient; they are costly and compromise the quality of care.

The High Cost of Rework

A single failed firing due to a bad seal results in a complete loss of the restoration. This translates directly to wasted technician time, expensive materials, and delays in delivering the final product to the dentist and patient.

Inconsistent and Unpredictable Results

A furnace with a minor, inconsistent leak becomes a source of frustration and unpredictability. Even when using identical materials and pre-set programs, the results will vary from one cycle to the next.

This lack of control makes it impossible to reliably achieve the desired aesthetic and functional outcome, eroding confidence in the lab's output.

Compromised Bond Strength

For PFM restorations, the bond between the porcelain and the metal framework is paramount. Uncontrolled atmosphere from a poor seal can disrupt the delicate oxidation layer required for a strong chemical bond.

The result is a weakened interface that is significantly more susceptible to chipping or delamination once in service in the patient's mouth, leading to premature failure.

Applying This to Your Practice

Your choice and maintenance of a dental furnace should be guided by an understanding that the seal is a critical control point for quality.

- If your primary focus is clinical consistency and patient satisfaction: Prioritize furnaces with a proven, robust sealing mechanism, as this is the foundation for predictable aesthetic and functional outcomes.

- If your primary focus is operational efficiency and cost control: Recognize that a superior seal directly reduces the rate of failed firings, saving significant costs in materials, labor, and rework.

- If your primary focus is working with advanced ceramics: Understand that a perfect seal is the non-negotiable prerequisite for the precise atmospheric control these sensitive materials demand.

Ultimately, the integrity of your furnace's seal directly translates to the integrity and longevity of the restorations you create.

Summary Table:

| Key Aspect | Importance in PFM Furnaces |

|---|---|

| Prevents Oxidation | Avoids weak bonds and discoloration by blocking external air contaminants. |

| Maintains Vacuum | Ensures dense, void-free porcelain by holding deep vacuum levels (e.g., -980 mBar). |

| Preserves Materials | Contains volatile components for better gloss, durability, and reduced porosity. |

| Ensures Consistency | Provides predictable outcomes, lowering rework costs and improving efficiency. |

Upgrade your dental lab's precision with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure a perfect fit for your unique PFM restoration needs, delivering superior sealing performance for consistent, high-quality results. Contact us today to discuss how we can enhance your operational efficiency and patient satisfaction!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab