In dental prosthetics, the quality of a porcelain furnace is not merely a feature—it is the determining factor in the final restoration's success. Superior firing performance is crucial because it ensures the precise control of temperature and time needed to transform ceramic powders into a strong, aesthetic, and perfectly fitting restoration. Without this control, the entire process is compromised, leading to clinical failures and financial loss.

A high-performance furnace is the bridge between a technician's skill and a predictable clinical outcome. Its role is to create a perfectly controlled environment where ceramic materials can achieve their maximum potential for strength, aesthetics, and longevity.

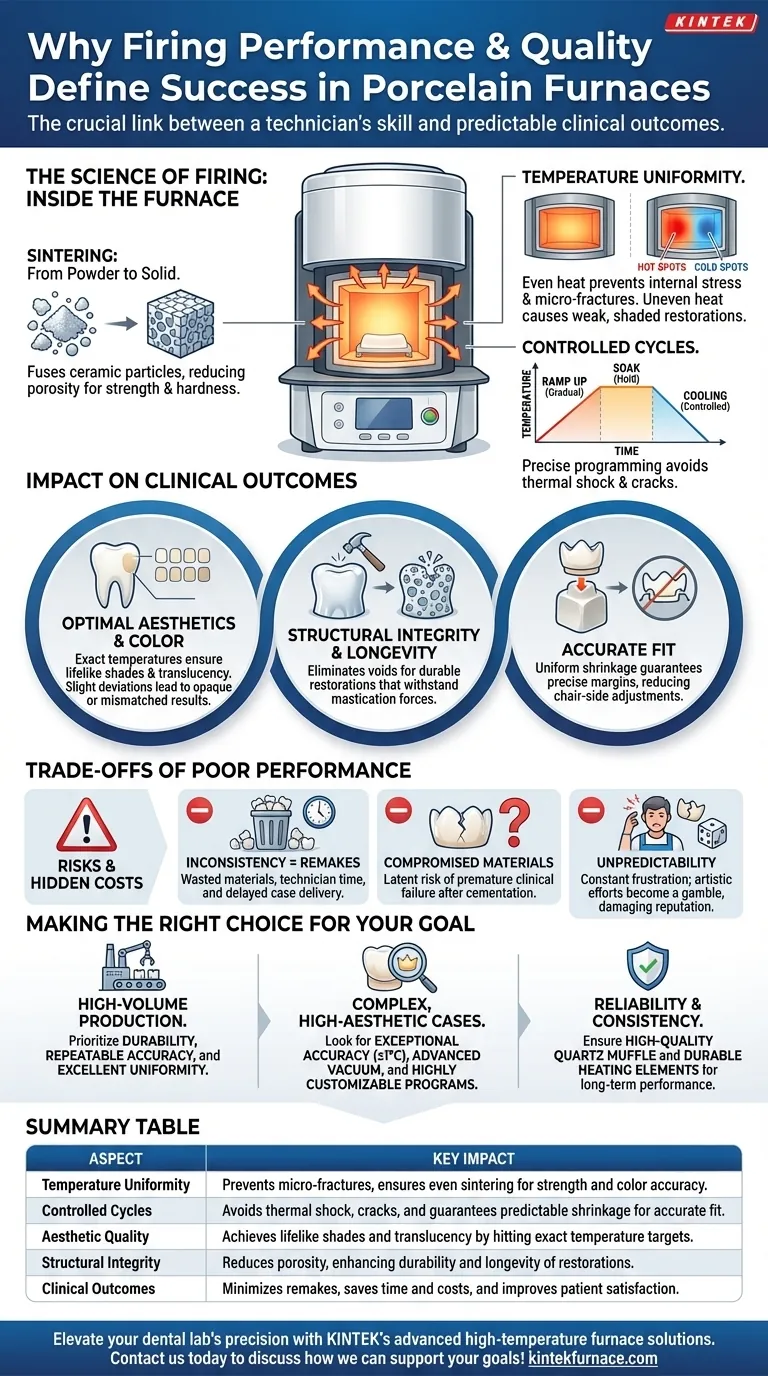

The Science of Firing: What Happens Inside the Furnace

To understand why performance is so critical, we must first understand the process of sintering, which is the technical term for firing porcelain.

From Powder to Solid

Sintering is a thermal process that fuses ceramic particles together, reducing porosity and increasing density. This is what gives a restoration its final strength and hardness.

The furnace's job is to execute this transformation flawlessly by managing extreme heat over specific time intervals.

The Critical Role of Temperature Uniformity

The heating elements in a furnace create an internal chamber, or muffle, that must maintain a perfectly even temperature.

If "hot spots" or "cold spots" exist, different parts of the restoration will sinter at different rates. This creates internal stresses, leading to micro-fractures, poor shade matching, and a structurally weak final product.

The Importance of Controlled Cycles

The firing process is not just about reaching a peak temperature. It involves several stages, including a gradual temperature increase, a holding (or "soak") period, and a controlled cooling phase.

A high-quality furnace allows for precise programming of these cycles. Abrupt temperature changes can cause thermal shock, resulting in cracks and total failure of the restoration.

How Firing Performance Directly Impacts Clinical Outcomes

A furnace's technical performance has a direct and measurable effect on the quality of the restoration that is ultimately placed in a patient's mouth.

Achieving Optimal Aesthetics and Color

Modern ceramic materials are designed to achieve specific shades and translucencies at exact temperatures.

Even a slight deviation from the manufacturer's recommended firing temperature can result in an opaque, lifeless appearance or a complete mismatch in color. A high-performance furnace hits these targets with precision, ensuring lifelike aesthetics.

Ensuring Structural Integrity and Longevity

The ultimate goal of sintering is to create a dense, non-porous ceramic. Porosity is the enemy of strength.

A furnace that provides uniform heating and accurate temperature control eliminates voids in the material, creating a restoration that can withstand the forces of mastication over many years. This directly reduces the risk of chipping or catastrophic fracture.

Guaranteeing an Accurate Fit

During firing, porcelain shrinks as it densifies. This shrinkage must be uniform and predictable.

Uneven heating from a poor-quality furnace causes unpredictable shrinkage, which can distort the restoration's margins and overall fit. This leads to chair-side adjustments, costly remakes, and compromised marginal integrity.

Understanding the Trade-offs of Poor Performance

Investing in a lower-quality furnace or neglecting the maintenance of an existing one introduces significant risks and hidden costs.

The Hidden Costs of Inconsistency

The most obvious cost of poor firing is the need for remakes. This wastes expensive ceramic materials, but more importantly, it wastes the technician's valuable time and delays case delivery.

The Risk of Compromised Material Properties

A restoration may look acceptable coming out of a subpar furnace, but it may not possess the physical properties (like flexural strength) intended by the manufacturer.

This creates a latent risk of premature failure after the restoration has been cemented, damaging the reputation of both the lab and the clinician.

The Challenge of Unpredictability

For a skilled dental technician, an unreliable furnace is a constant source of frustration. It makes their artistic and technical efforts a gamble.

Predictability is the cornerstone of a professional laboratory. A high-performance furnace removes variables and ensures that the technician's work is accurately translated into the final product.

Making the Right Choice for Your Goal

When evaluating a porcelain furnace, your decision should be guided by the specific demands of your laboratory or practice.

- If your primary focus is high-volume production: Prioritize a furnace known for its durability, repeatable cycle accuracy, and excellent temperature uniformity across the entire firing tray.

- If your primary focus is complex, high-aesthetic cases: Look for a furnace with exceptional temperature accuracy (within 1°C), advanced vacuum control, and highly customizable, multi-stage programming.

- If your primary focus is reliability and consistency: Ensure the furnace is built with a high-quality quartz muffle and durable heating elements, as these components are critical for long-term performance and predictable results.

Ultimately, investing in quality firing performance is an investment in predictable outcomes, clinical excellence, and the reputation of your work.

Summary Table:

| Aspect | Key Impact |

|---|---|

| Temperature Uniformity | Prevents micro-fractures and ensures even sintering for strength and color accuracy |

| Controlled Cycles | Avoids thermal shock, cracks, and guarantees predictable shrinkage for accurate fit |

| Aesthetic Quality | Achieves lifelike shades and translucency by hitting exact temperature targets |

| Structural Integrity | Reduces porosity, enhancing durability and longevity of restorations |

| Clinical Outcomes | Minimizes remakes, saves time and costs, and improves patient satisfaction |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Vacuum Furnaces, tailored to meet your unique needs for high-volume production or complex aesthetic cases. Our deep customization ensures reliable, consistent results that enhance your clinical outcomes. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision