Indirect rotary kilns are the standard for lithium processing because they provide the precise, controlled environment required for the acid roasting stage. This process converts stable beta-spodumene ore into water-soluble lithium sulfate, a critical step that allows for high-purity lithium to be leached and recovered efficiently.

The core challenge in processing hard-rock lithium is the chemical conversion of the ore, not just heating it. Indirect kilns are recommended because they separate the heating source from the material, creating the specific, non-reactive atmosphere needed for the acid roasting reaction to succeed at maximum efficiency.

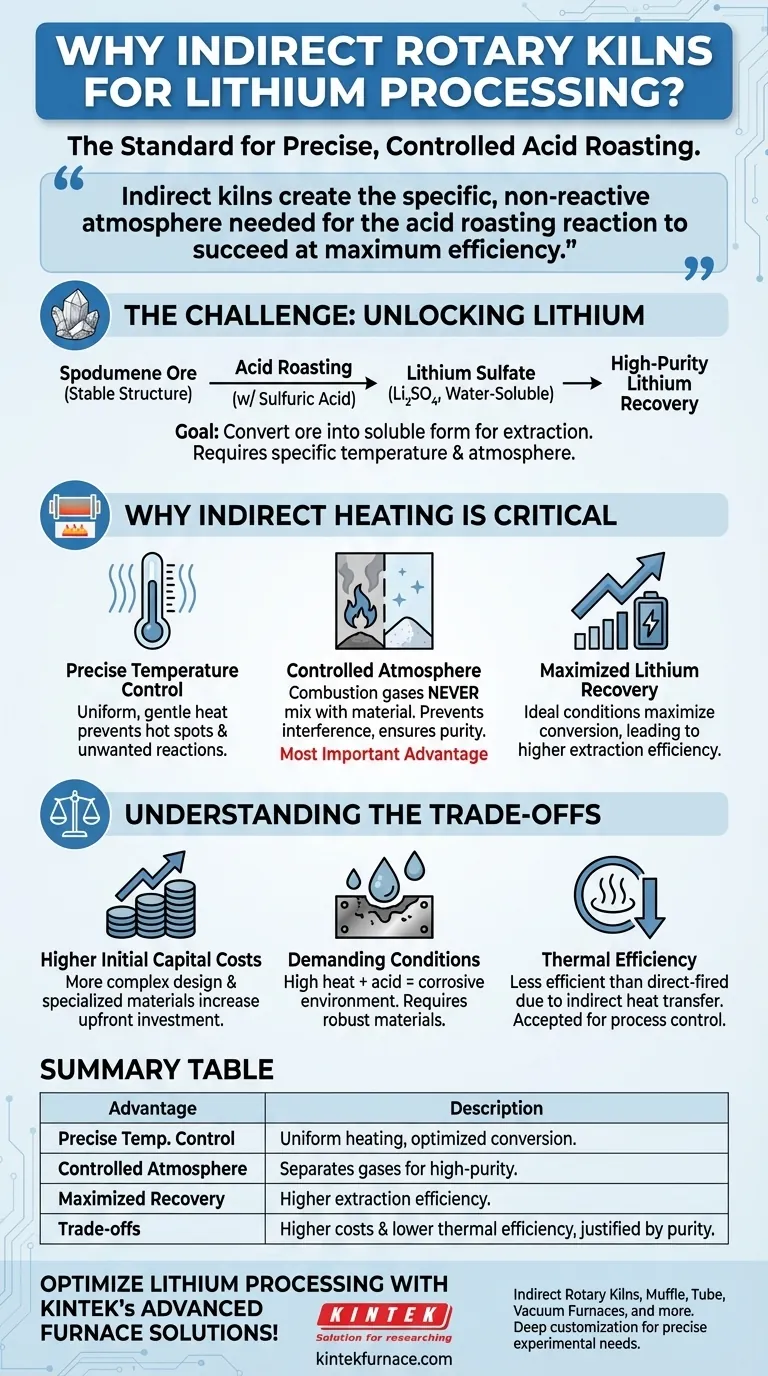

The Core Challenge: Unlocking Lithium from Spodumene

To understand the kiln's role, you must first understand the material it processes. Spodumene ore is the starting point, and it holds lithium in a very stable crystalline structure.

### The Goal: Acid Roasting for Solubility

The primary goal is to convert the lithium within the ore into a form that can be easily dissolved in water. This is achieved through a process called acid roasting.

In this stage, the prepared ore (beta-spodumene) is mixed with an acid, typically sulfuric acid, and heated. The reaction forms lithium sulfate (Li₂SO₄), which is highly soluble in water.

### Why Standard Heating Fails

Simply heating the material in a generic kiln is not sufficient. The chemical reaction has specific requirements for both temperature and atmospheric purity that must be met.

Why Indirect Heating is Critical for This Process

An indirect rotary kiln is purpose-built to meet the unique demands of acid roasting. Its design is fundamentally different from a direct-fired kiln, where the flame and combustion gases come into direct contact with the material.

### Precise and Uniform Temperature Control

The conversion to lithium sulfate occurs within a specific temperature range. Indirect heating, where the kiln's outer shell is heated, provides exceptionally uniform and gentle heat transfer to the material inside.

This prevents hot spots that could cause unwanted side reactions or decompose the target product, ensuring a consistent and high-quality conversion.

### Maintaining a Controlled Atmosphere

This is the single most important advantage. In an indirect kiln, the combustion gases from the heat source never mix with the process material.

This separation is critical because combustion byproducts could interfere with the acid roasting chemistry, reducing efficiency and purity. It ensures the reaction between the spodumene and the acid proceeds exactly as intended.

### Maximizing Lithium Recovery

By providing the ideal conditions—precise temperature and a clean atmosphere—indirect kilns maximize the conversion of spodumene to lithium sulfate.

This directly translates to higher lithium recovery rates. More of the lithium from the initial ore is successfully extracted, improving the economic viability and efficiency of the entire operation.

Understanding the Trade-offs

While ideal for the chemistry, the choice of an indirect kiln involves clear engineering trade-offs.

### Higher Initial Capital Costs

Indirect kilns are more complex than their direct-fired counterparts. They require an external combustion chamber and often use specialized alloys for the rotating shell to handle high temperatures and corrosion, leading to a higher upfront investment.

### Demanding Process Conditions

The combination of high heat and sulfuric acid creates an extremely corrosive environment. The long-term reliability of the kiln depends on robust material science and a design that can withstand these demanding conditions.

### Thermal Efficiency Considerations

Because heat must transfer through the kiln shell to the material, the process is inherently less thermally efficient than a direct-fired system. However, this trade-off is accepted to achieve the process control and purity required for lithium production.

Making the Right Choice for Your Goal

The recommendation for indirect kilns in lithium processing is not arbitrary; it is a direct consequence of the underlying process chemistry.

- If your primary focus is maximizing lithium recovery and product purity: The atmosphere separation and precise temperature control of an indirect kiln are non-negotiable for successful acid roasting.

- If your primary focus is long-term operational efficiency: Higher yields from an optimized indirect kiln process can significantly reduce downstream processing costs and waste, justifying the initial investment.

- If your primary focus is process reliability: Choose a kiln designed with materials specifically selected to resist the high-temperature, acidic environment inherent to converting spodumene.

Ultimately, selecting an indirect rotary kiln is a decision rooted in prioritizing the chemical integrity of the conversion process above all else.

Summary Table:

| Advantage | Description |

|---|---|

| Precise Temperature Control | Ensures uniform heating to prevent hot spots and unwanted reactions, optimizing lithium sulfate conversion. |

| Controlled Atmosphere | Separates combustion gases from material, maintaining a non-reactive environment for high-purity acid roasting. |

| Maximized Recovery Rates | Achieves higher lithium extraction efficiency by providing ideal conditions for the chemical reaction. |

| Trade-offs | Higher initial costs and lower thermal efficiency, but justified by superior process control and purity. |

Optimize your lithium processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide indirect rotary kilns and other systems like Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing recovery rates and purity. Contact us today to discuss how we can support your goals in lithium extraction and beyond!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is an industrial-grade rotary reactor necessary in the oil sludge pyrolysis process? Maximize Yield & Efficiency

- How does a rotary furnace compare to a fixed-bed furnace for powder? Optimize Uniformity in Large-Scale Production

- What is the working principle of a pyrolysis rotary kiln reactor? Efficient Waste-to-Energy Conversion

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- Why must precise temperature measurement and upper-limit control be implemented during the rotary furnace melting of ductile iron?