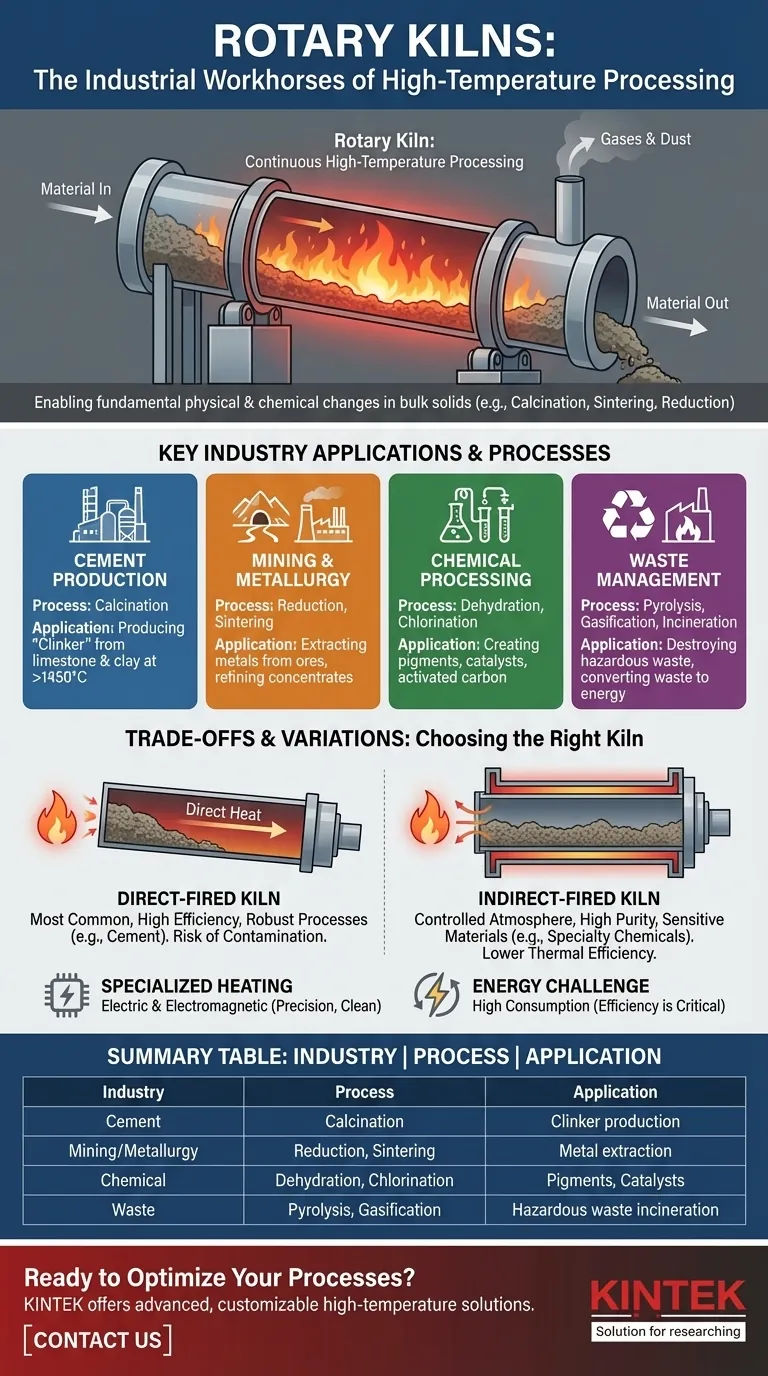

At their core, rotary kilns are the industrial workhorses for high-temperature material processing. They are indispensable in sectors like cement manufacturing, mining and metallurgy, chemical processing, and waste management. These industries rely on kilns to induce fundamental physical or chemical changes in bulk solids through processes like calcination, sintering, and reduction.

The widespread use of rotary kilns stems from a single, powerful capability: their ability to continuously process large volumes of solid materials at extreme temperatures, making them the default solution for countless thermal transformation processes.

The Core Function: Enabling High-Temperature Transformation

A rotary kiln is, in essence, a large, rotating, cylindrical vessel inclined at a slight angle. This simple design is what makes it so versatile and effective for industrial-scale thermal processing.

The Principle of Continuous Processing

The kiln's rotation and gentle slope ensure that material fed into the higher end travels continuously toward the lower end. This constant tumbling motion exposes the entire surface area of the material to heat, guaranteeing uniform processing.

The Power of Thermal Treatment

The intense heat inside a kiln is the catalyst for transformation. Different industries harness this heat to achieve specific outcomes, including:

- Calcination: Heating a solid to a high temperature to cause decomposition, often driving off a component like carbon dioxide or water.

- Sintering: Heating materials to just below their melting point, causing particles to fuse together into a solid, porous mass.

- Reduction: Removing oxygen from a compound, a critical step in turning metal ores (like iron oxide) into pure metals.

- Pyrolysis & Gasification: Decomposing organic material at high temperatures in the absence or with limited oxygen, often used in waste treatment.

A Breakdown of Key Industrial Applications

While the principle is the same, the application of rotary kilns is highly specific to the industry's goal.

Cement Production: The Cornerstone Application

The cement industry is the single largest user of rotary kilns. Here, they are used to calcine a precise mixture of limestone, clay, and other materials at over 1450°C (2640°F) to produce "clinker," the essential component of modern cement.

Mining and Metallurgy: Extracting and Refining Metals

In metallurgy, kilns are vital for the initial stages of metal production. They are used for the reduction roasting of ores, such as turning iron ore into direct-reduced iron, or for smelting concentrates to separate valuable metals.

Chemical and Mineral Processing: Creating Essential Compounds

The chemical industry uses kilns for a variety of tasks, including dehydration to remove water from compounds, chlorination reactions, and the production of pigments or catalysts. They are also used to create products like activated carbon through controlled heating.

Environmental and Waste Management: Neutralizing and Repurposing

For waste management, rotary kilns serve as high-temperature incinerators. They are exceptionally effective at destroying hazardous organic waste and can be used in gasification processes to convert waste into energy, demonstrating their role in environmental remediation.

Understanding the Trade-offs and Variations

While powerful, a rotary kiln is not a one-size-fits-all solution. The specific design is chosen based on critical trade-offs between efficiency, purity, and cost.

Direct vs. Indirect Firing

A direct-fired kiln is the most common and thermally efficient design, as the flame and combustion gases are in direct contact with the material. This is ideal for robust processes like cement production.

An indirect-fired kiln heats the material through the shell of the rotating drum, keeping the material isolated from the combustion gases. This prevents contamination and is necessary when product purity is paramount, such as in specialty chemical or food-grade applications.

Specialized Heating: Electric and Electromagnetic

For processes requiring extreme precision or involving highly sensitive materials, electric or electromagnetic induction kilns offer unparalleled temperature control. They use resistance heating or magnetic fields to generate heat, eliminating combustion byproducts entirely, though at a higher operational cost.

The Challenge of Energy Consumption

The primary trade-off of any kiln operation is its significant energy consumption. The process of heating massive volumes of material to thousands of degrees is inherently energy-intensive, making thermal efficiency a critical factor in kiln design and operational profitability.

Making the Right Choice for Your Goal

Selecting the right kiln technology depends entirely on the material being processed and the desired outcome.

- If your primary focus is high-volume commodity production (like cement or lime): A large, direct-fired kiln is the standard for its unmatched throughput and thermal efficiency.

- If your primary focus is material purity or sensitive chemical reactions: An indirect-fired kiln provides the necessary controlled, non-contaminating atmosphere.

- If your primary focus is waste treatment or resource recovery: A kiln designed for high-temperature incineration or gasification is required to ensure complete destruction of hazardous components.

- If your primary focus is refining high-value metals or specialty chemicals: An advanced electric or electromagnetic kiln may be justified for its precision and granular control over the process.

Ultimately, the rotary kiln’s value lies in its unique ability to transform raw, bulk materials into foundational products through the precise application of heat.

Summary Table:

| Industry | Key Processes | Primary Applications |

|---|---|---|

| Cement Production | Calcination | Producing clinker from limestone and clay at high temperatures |

| Mining and Metallurgy | Reduction, Sintering | Extracting metals from ores, refining concentrates |

| Chemical Processing | Dehydration, Chlorination | Creating compounds like pigments, catalysts, activated carbon |

| Waste Management | Pyrolysis, Gasification | Incinerating hazardous waste, converting waste to energy |

Ready to optimize your industrial processes with advanced high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge rotary kilns and other furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental and production requirements, enhancing efficiency and outcomes. Contact us today to discuss how our tailored solutions can benefit your operations!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing