At its core, a box furnace is a versatile tool capable of heat treating a wide range of material forms and geometries. It is well-suited for processing parts such as heavy welded fabrications, forgings, large plates, and various spun products due to its simple, accessible chamber design.

The true value of a box furnace is not defined by the specific metal it can heat, but by the fundamental thermal processes it can perform. It is a general-purpose workhorse for common heat treatments that do not require specialized atmospheric control.

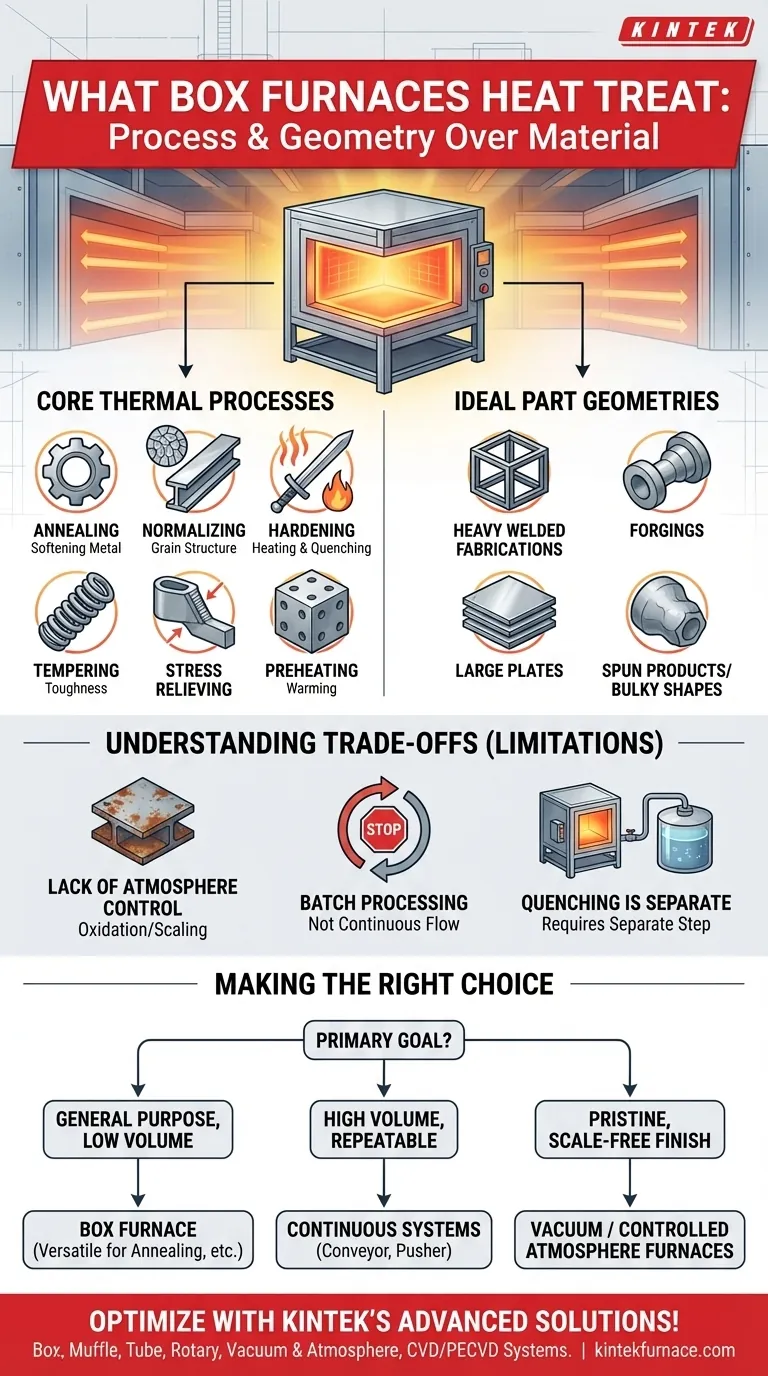

What a Box Furnace Actually Does

To determine if a box furnace is right for your needs, you must look past the material itself and focus on the required thermal process and the physical shape of the parts.

The Focus is on the Process, Not the Material

A box furnace is essentially a high-temperature oven. Its primary function is to apply heat to a part in a controlled manner over a set period in a standard air atmosphere.

The critical question is not "Can it heat my steel part?" but rather "Can it perform the annealing cycle my steel part requires?"

Core Thermal Processes Performed

Box furnaces excel at a range of common, non-atmospheric heat treatment applications.

- Annealing: Softening a metal to improve its ductility and make it easier to machine or form.

- Normalizing: Refining the grain structure of steel to improve its mechanical properties, particularly toughness.

- Hardening: Heating a metal (typically steel) to a critical temperature and then rapidly cooling it (quenching) to increase its hardness and strength. The furnace only performs the heating portion of this cycle.

- Tempering: A low-temperature heat treatment performed after hardening to reduce brittleness and increase toughness.

- Stress Relieving: Heating a part to a temperature below its transformation range to relieve internal stresses introduced during manufacturing processes like welding or machining.

- Preheating: Warming a part, often a die or a large weldment, to a specific temperature before another process begins.

Ideal Part Geometries

The "box" design makes this furnace exceptionally useful for parts that are bulky, irregularly shaped, or simply too large for other furnace types.

Common examples include individual large forgings, die blocks, custom-fabricated frames, and stacks of plate material that can be easily loaded and unloaded.

Understanding the Trade-offs

A box furnace is a powerful tool, but its utility has clear boundaries. Understanding its limitations is critical to avoiding costly mistakes.

Lack of Atmosphere Control

A standard box furnace operates in ambient air. During high-temperature heating, the oxygen in the air will cause oxidation (scaling) on the surface of most metals.

For applications where a bright, scale-free finish is required, you must use a specialized furnace with a controlled atmosphere (e.g., nitrogen, argon) or a vacuum furnace.

Batch Processing vs. Continuous Flow

By design, a box furnace is a batch processing tool. Parts are loaded, the door is closed, the cycle runs, and the parts are unloaded.

This is inefficient for high-volume, continuous production lines where a conveyor or pusher furnace would be a more appropriate choice.

Quenching is a Separate Step

For processes like hardening, the cooling rate is as important as the heating temperature. A box furnace only handles the heating.

You must have a separate, properly sized quenching system (oil, water, or polymer tank) located nearby to cool the parts rapidly and achieve the desired hardness.

Making the Right Choice for Your Goal

Select your equipment based on the process requirements and production goals, not just the part's material.

- If your primary focus is general-purpose, low-volume heat treatment: A box furnace is an excellent and highly versatile choice for annealing, stress relieving, and tempering a wide variety of parts.

- If your primary focus is high-volume, repeatable production: You should investigate continuous furnace systems like conveyor or pusher furnaces that integrate into an automated production line.

- If your primary focus is a pristine, scale-free surface finish: You must use a vacuum furnace or a furnace with a controlled inert atmosphere.

Matching the tool to the task is the foundation of efficient and effective thermal processing.

Summary Table:

| Material Type | Common Forms | Key Processes |

|---|---|---|

| Metals (e.g., Steel) | Forgings, Plates, Welded Fabrications | Annealing, Hardening, Stress Relieving |

| Various Alloys | Spun Products, Large Parts | Normalizing, Tempering, Preheating |

Optimize your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Box, Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control